Sumitomo Electric Carbide adds to their WDX collection - sumitomo carbide insert

Coating. For interrupted turning, an insert with a physical vapour deposition (PVD) coating on the substrate will help extend tool life. PVD coatings are tougher than chemical vapour deposition (CVD) coatings.

Coolant. The issue of thermal stress leads some operators to believe that running the machine with coolant is the best option.

“There needs to be a balance,” said Goss. “You don't want to have too much negativity or a large land on some of those soft, ductile materials, which could lead to excessive cutting force. But it also needs to be heavy enough to provide adequate performance and tool life.”

And he hammers home the higher speed and feed message: “Today, the world is changing and today we are saying, go for higher feed rates, even when machining 60 HRc; forget the old times when you would run at low speed and feed, run at higher values, like woodworking. Change from large depths of cut to small depths of cut, because, if you go to 3D [printing], there is less to take off.” Harpaz points to face-milling at 3.5 mm per tooth as a possibility now; before it would have been 0.35 mm per tooth. And consider hard turning rather than grinding for materials of 50 HRc and up, he advises, stating that the surface finish will be “much better than grinding”.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

Then, in 1982, an indexable system was developed that cut that to 1 minute 5 seconds. This was followed by the Tang Grip system, in 2004, that delivered 45 seconds, which was bettered by Jet Line insert toolholders having coolant delivery that reduced that to 35 seconds. Then, with the flat-top Tang-Grip-IQ blade, the current product, the time to part-off through 100 mm is 25 seconds.

The company also offers the narrowest indexable insert slitting saw, Slim-Slit, a 32 mm diameter blade that holds inserts 0.6-1.2 mm wide (the Logiq-Slim insert mentioned previously) – performance is three times faster than a solid carbide slitting saw and 10 times that of HSS, Harpaz underlines. Fast, simple insert change and directed coolant delivery to flush out swarf via special shanks feature.

“For interrupted-style cuts on hardened material, it’s best to choose heavier edge preparations,” said Goss. “With ceramic, having a large single or compound chamfer/land, or with carbide, having a heavier-duty chip form, will ensure the insert is able to handle the abusive nature of the cut and redirect those forces appropriately to allow for maximum tool life.”

“When it comes to ceramics, you want to avoid this temptation,” said Lobsinger. “It’s the first thing an operator will do when they start thinking something is going wrong, but you definitely don’t want to do that. The amount of increase in the recommended speed in severely interrupted cuts can usually be calculated. The operator can calculate the circumference of the part, then subtract the total sum of the interruptions. This will give a smaller diameter value, which increases the SFM. Essentially, when increasing cutting speed, you're reducing the time the insert spends out of the cut, thus reducing how much time the insert has to cool, ultimately reducing thermal stress and the growth of the cracks.”

Levels of interrupted cuts can vary anywhere from a light interruption, which might account for only 10 to 20 per cent of the overall process, to a heavy interruption which can be 60 to 75 per cent or more of the overall process. Regardless of how you define interrupted cutting, there are some points to consider when undertaking an interrupted operation.

ISCAR’s president revealed the company’s latest tooling developments to an audience of some 270 at Birmingham’s ICC in March. The main thoroughfares of the venue were decked with video screens and large hanging banners (cover image) to announce the event to those attending and passing through – these ISCAR (https://is.gd/tuhuno) undertakings are far from the usual product launch. And this was just one of a series of events on a world tour that Harpaz undertakes to spread the news of his company’s newest innovations, of which there are many.

Choosing the right grade depends on the type and hardness of the material, as well as the level of interruption and the machining stage, whether roughing or finishing.

Turning to new products, Harpaz offers some general themes that he gathers together under the banner ‘machining intelligently’, starting with attacking bottlenecks in milling, drilling, turning, grooving and parting off as the target for all the revealed developments. Of course, productivity can be boosted by investing in latest machine tools, but machines are not bought every day, so tooling can deliver through higher speeds and feeds. “Speed comes from the carbide grade and today ISCAR is offering very innovative grades, also taking in coatings, for any application,” the president underlines, adding later that large improvements are being gained via post-treatment of inserts.

With carbide grades, having either a large grain size or cobalt-enriched layer as part of the substrate will make for a stronger insert. Larger carbide grains have more impact on strength compared to a fine-grade carbide.

A further key theme is chip evacuation: “If you solve the problem of chip evacuation, you can go to much higher feeds,” he offers, adding that surface finish is also improved. And chip evacuation is achieved via coolant delivered directly to the cutting edge, a feature of many of the new products.

Interrupted cutting in turning is subjective. While some operators may look at a part with a keyway and a small depth of cut as a heavy interruption, another operator may classify heavy interruptions only as multiple interruptions with a larger depth of cut. The workpiece material, part configuration and features, and depth of cut will all come into play when determining how the interruption will affect the overall process.

Logiq-5-Grip, pushes this five-edge, solid insert system further on economy and performance. The current blade can employ existing 2-3 mm wide Tang-Grip inserts and can cut diameters up to 45 mm. Coolant directed at the cutting edge again features. But a new system is smaller, employing 0.8-1.6 mm wide Logiq-Slim inserts for parting diameters up to 22 mm – “The smallest width indexable insert for parting off and grooving.” When using 3 m bar and parting off components 10 mm in length, a 2 mm width insert will support production of 250 parts; 0.6 mm width inserts offer 283. Inserts are easily replaced with a simple tool in both cases – no set-up time.

When you are considering carbide grades, having either a large grain size or cobalt-enriched layer as part of the substrate will make for a stronger insert. Tungaloy

ISCAR’s Pentacut, cost-effective five-edge single, ‘star-type’ insert system for grooving and parting has proved successful, but the company has introduced a system for smaller parts, called Pentacut Miniature Master, that uses a size 17 insert system (previous systems were 24 and 34). Insert widths are 0.25 to 3.18 mm. Coolant delivery above and below the insert again features. Swiss-type sliding-head machines are a key target.

“If you have the corresponding toolholders in your facility already, a round insert is the strongest,” said Haid. “With a round insert, a rigid setup is necessary to take the impacts of the interrupted cuts. A square insert would be the second strongest. For the most part, diamond-shaped inserts are not well suited, but some interruptions could require a specific insert to get in and perform the cut.”

So, in citing a part that takes 18 seconds to machine, a 30% discount on cutting tool costs gets you a 1% part cost reduction, doubling tool life gets you 1.5%, but increasing speed and improving the process can deliver a 15% cost reduction, Harpaz underlines – that is ‘machining intelligently’ with the new ‘Logiq Chess Line’ tools.

For example, a hard grade of carbide will run faster and last longer but is more brittle, whereas a tough grade of carbide has impact resistance but runs slower and does not last as long.

Short set-up times, even zero set-up times, are another element in boosting productivity, and ISCAR has examples to offer in this area, too. For example, Multi-Master SolidMill solid carbide end-mills with replaceable tips that require no toolholder removal from the machine or presetting; also, the Swiss-Cut turning tool that can have its insert changed without the need to remove a screw – “it takes just a second to replace an insert”.

“A simple example of this would be 50 per cent of the material taken away by voids or interruptions at the surface,” he said. “Fifty per cent of the surface remains in contact with the tool compared to an interrupted part. So, in this case, double the SFM to compensate for that.”

Every five years, or so, tooling giant ISCAR unveils a major package of developments, revealed via a number of global roadshows fronted by company president Jacob Harpaz. Andrew Allcock was in the audience and reports on the company’s latest innovations

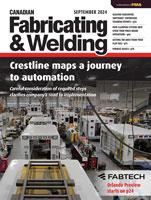

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

Regardless of how a shop classifies interrupted cuts, interruptions can present themselves in a couple of different ways.

A rigid setup is necessary for interrupted cuts to take the impact. A round insert is the strongest, followed by a square insert. Dormer Pramet

“Most commonly, an interruption is a break in the continuity of the material during the machining process,” said Matt Goss, applications engineer and project development, Greenleaf Corp., Saegertown, Pa. “This is where the insert engages and disengages with the workpiece, either once or a series of times. These interruptions can either be induced as part of the machining process, such as turning over bolt circles or holes, slots, or keyways, or they can be inherent to the workpiece, for example if it is out of round or has forging scale on the surface. Each of these cases presents a scenario where there's a break in continuous and uniform flow of material across the cutting tool.”

The experts noted that some operators tend to favour a positive geometry as they think it will help take the impact, but that is just not the case. A negative geometry is going to provide a much better cut in interrupted turning.

With interrupted cuts there is a greater risk for the cutting edge to break down prematurely or inconsistently, lowering part quality. It is important to choose the best cutting tool and process parameters during interrupted turning operations. Phuchit/iStock/Getty Images Plus

Why be concerned about cutting tool innovation, though? Cutting tools represent just 3-4% of production costs. True, but they have a leveraging effect on other costs.

This mention of 3D printing is picked up more strongly, with the president highlighting that tooling will be getting smaller, due to the material volumes being removed shrinking, especially in turning – precision casting will similarly result in less material to remove, he notes. Smaller tools have the benefit of not requiring so much cobalt in their manufacture, a material whose price and availability are both being negatively hit by the demand for electric car batteries.

For interrupted cuts in softer or more ductile materials, having an edge prep with a larger or wider land is a good option. With ceramic, the insert does not need to be as negative as it would for a harder material; with carbide, a medium-duty chip form will provide additional shear, which is beneficial in most cases.

Haid added that it’s always better to start on the low end of the feed rate to provide a bit of wiggle room, rather than running a little bit slow. Running slow can put more impact on the insert.

“However, with ceramics, we would recommend opting for a silicon-carbide, whisker-reinforced ceramic insert or a silicon nitride-based ceramic over an alumina-based or white ceramic, as it will provide much more strength and reliability,” said Goss.

ISCAR is a €3 billion turnover metal cutting tool specialist, having notched up a record year in 2017, the president underscored ahead of the technical proceedings, adding that, based on Q1 figures, 2018 is anticipated as bettering that. ISCAR is part of IMC, which includes TaeguTec, Tungaloy and Ingersoll Cutting Tools. The IMC Group is the second largest company in the world for metalworking tools, comprising 13 companies. It has over 130 subsidiaries in 60 countries. ISCAR employs some 3,200 at its headquarters in Israel, with around 10% involved in R&D, into which the company sinks 4-5% of turnover. And 40% of turnover comes from products that are under five years old.

Lobsinger explained that the smaller diameter value basically returns the operator back to the original recommended surface speed he is trying to achieve.

Extra-long inserts for the Swisscut system are also pointed up. This range supports threading, parting, turning, back turning and groove turning. Parting off up to 20 mm, rather than the previous 7.5 mm is key, but also underlined is the ease with which inserts can be replaced. Two screws are loosened (not removed) and the insert withdrawn – zero set-up time.

Choosing the right insert for interrupted turning can make all the difference in success of the overall process. One of the big misconceptions is that operators can just use whatever insert is available. Sometimes this may work out, but often operators will struggle.

Optimal strength is going to be realized by using a round geometry and a negative-style insert. Mitchell also noted that it’s important to pay attention to the chipbreaker selection. Some chipbreakers are designed for heavy interruptions, but others are designed to be free cutting and as sharp as possible, making them fragile and prone to chipping in an interrupted application.

“However, coolant should almost always be shut off, unless machining an extremely gummy material,” said Mitchell. “When coolant is applied to an insert machining an interrupted cut, the insert undergoes extreme heat, then no heat when encountering the interruption. The hot insert is then suddenly submerged in coolant, which causes thermal cracking, shortening the tool life and potentially causing catastrophic failure.”

Innovation that builds on Pentacut, Logic-5-Grip. The existing blade (left) can employ existing 2-3 mm wide Tang-Grip inserts and can cut diameters up to 45 mm. A new smaller system (right) uses 0.6-1.6 mm wide Logiq-Slim inserts for parting diameters up to 22 mm wide

“For roughing applications, I would like to have a tougher grade with a larger T-land or a roughing chipbreaker with a nice edge prep to maintain the interruptions as well as hold that dimensional tolerance,” said Haid. “When finishing, go with something harder rather than something tougher to hold the tolerance and not wear out as fast.”

Easily access valuable industry resources now with full access to the digital edition of Canadian Metalworking.

Other new introductions highlighted were: Jet-R-Turn/Jet Master rigid toolholders offering coolant channels for standard and high pressure coolant delivery from above and below the insert, three coolant inlet positions and easy insert changing; Logiq-4-Turn, economical double-sided 80° positive inserts for alloy steel, plus toolholders that deliver coolant to the cutting edge; Alu-P-Turn 35° and 80° inserts for aluminium that boast four cutting edges and 9 mm cut depth, not 12 mm, for economy (re the earlier cobalt cost comment), for use with existing Flashturn holders; Whisperline anti-vibration boring heads, recommended for 7-10xD; Nanmill 8 and 10 mm diameter indexable insert end-mills with two and three cutting edges respectively, offering 3 mm depth of cut and fast insert change; Heli-3-Mill 90° corner insert system now in diameters 10, 12 and 16 mm; Tangfin face-mills for micron-level surface finishing with tangentially-clamped inserts having four cutting edges, 50-160 mm diameter; and Logiq-8-Tang face-mill with inserts having eight cutting edges (four before), 40-125 mm diameter. ■

Lindsay Luminoso, sr. editor/digital editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

According to John Mitchell, general manager, Tungaloy Canada, Brantford, Ont., carbide cutting tools are made primarily of tungsten, a very hard, wear- resistant material that is bound together with cobalt. To produce a grade capable of handling interrupted cuts, traditionally cutting tool manufacturers simply used more cobalt. On the other hand, to make the insert more wear-resistant, capable of faster cutting speeds and longer tool life, manufacturers used grades that had less cobalt and more tungsten.

Some of the impacts of interrupted cuts on the turning process can, depending on the severity of the interruption, lead to accelerated tool wear. This increased tool wear can lead to more tool changes during the process, which ultimately leads to an increase in part cycle times and an overall increase in labour and tooling costs for the job. Here are some factors to consider to help limit tool wear.

The impacts of interrupted cuts will depend on the process itself, whether it’s a roughing or finishing application. For the most part, roughing applications tend to include interruptions from forged or cast workpieces that are irregular in material or non-concentric shapes.

Now, with a combination of both new toolholder (‘the hardware’) and insert (‘the software’), the Tang-F-Grip system that is only for high feed cutting sees that 25 seconds becomes 15 seconds. Although that’s for traditional X-axis direction parting; for Y-axis direction parting using the same insert, that is slashed again, to 10 seconds. Of course, coolant to the cutting edge is key. But that’s not the end of it; there is also a holder that will allow Y-axis benefits for X-axis parting that will deliver a cutting time of just 7.5 seconds.

“Tungaloy developed a technology that was able to draw the cobalt to the outer edges of the insert, giving just the cutting edge a higher concentration of cobalt,” said Mitchell. “This allowed for the best of both worlds: a carbide grade with a high concentration of tungsten to allow for higher cutting speeds and longer tool life, while at the same time providing additional concentration of cobalt at the cutting edge to provide additional impact resistance.”

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

For deep parting and grooving in long overhang situations, a new holder having an anti-vibration feature counteracts vibrations – Whisperline. Offered with 5.5, 7.7 and 8 mm wide inserts, tool life is four times greater than the alternative, says Harpaz. Coolant delivery to the insert through the blade body again features.

Introducing ISCAR's Latest Products for 2024: QUICK-T-LOCK A Revolutionary 3 Cutting Edged Insert with SAFE-T-LOCK for Enhanced Multi Directional Performance.

Geometry. Another consideration for interrupted cutting is the geometry of the insert. Choosing an insert that has a small nose angle and long, narrow cutting edge does not offer the rigidity needed in most interrupted cutting applications.

Shape. The experts agree that while different shapes of inserts may work, a round insert is the best option, followed by a square insert.

Moving to single-ended inserts for parting off, in 1978, 100 mm took four minutes, using brazed tip tools, but ISCAR developed a system that had a chip breaker and that cut the time to 1 minute 30 seconds.

Turning first to Grip systems for parting and grooving, he says that while others also can offer double-ended parting inserts, ISCAR’s system has the capability to allow for depths that exceed the insert length, due to its twisted Do-Grip insert design that protects the reverse end. While still retaining the same insert, which can cut through 100 mm in 35 seconds, by delivering coolant through the holder (JHP style) from above and below the insert cutting edge to improve chip evacuation, that 35 seconds becomes 25 seconds, with no need to use high pressure coolant, unless cutting challenging aerospace materials. Other inserts are available that have coolant delivery holes in them, further aiding chip evacuation.

X- and Y-axis turning innovation was underlined, with parting off in 100 mm diameter material now possible in 7.5 seconds

An interruption also can be experienced not in the physical sense of material discontinuity, but by an inconsistency in material hardness or having heterogeneity in the material makeup of the workpiece. Goss explained that heterogeneity in the material can occur because of precipitates or inclusions that form during the manufacturing process of the parent material. If these precipitates or inclusions are congregated in one area of the workpiece, they can also act as an interruption during the machining process.

“Although positive inserts are generally not recommended for interrupted cuts, sometimes they are unavoidable,” said Mitchell. “In situations such as these, it is highly recommended to use a double-sided positive insert. Traditional positive inserts sit in a pocket and the only thing preventing them from moving is a small screw. But [some inserts] utilize a dovetail pocket, ensuring no movement even in interrupted applications, while still providing a positive cutting action.”

“The benefit of dealing with interrupted cuts in the roughing stage is that the insert can be changed, from part to part, without an offset,” said Matthew Haid, application specialist, Dormer Pramet, Mississauga, Ont. “Dealing with interrupted cuts in finish-turning can be much more challenging. If the part has a tight finishing tolerance, operators typically need to adjust the tool wear offset on the CNC over the course of the insert’s life. When changing the insert, it's recommended not to start at zero or the regular offset, but rather do a first pass to confirm the tolerance dimension. Both interrupted roughing and finishing can be a challenge, but with roughing, there is always material left to be finished, whereas finishing tends to be more sensitive.”

“PVD coatings have a thin layer that really holds up better against the impacts of interruptions versus the CVD option,” said Haid.

Another area of development is in reducing the power/energy required to cut metal, which Harpaz refers to as ‘easy cut’. This also has the effect of prolonging tool life, he advises. An associated cutting by-product is vibration, another area where ISCAR has developed solutions.

Moving to milling and a miniature slitting cutter, Min-Slit, is claimed to be the smallest diameter indexable insert such tool available – 16-28 mm diameter with insert widths 2-3 mm, with those inserts having two cutting edges for greater economy. Employing special insert geometry and coolant directed to the insert, high productivity is possible. Fast insert change is again underlined. Multi-Master or Flexfit bodies are employed – no set-up time.

“Basically, you want to look for the strongest insert possible,” said Paul Lobsinger, sales and service engineer Canada, Greenleaf Corp. “It helps to have a tough negative insert to accept the interruptions and pounding.”

Speeds and Feeds. The experts agree that one of the biggest mistakes an operator can make during interrupted turning is to reduce speed.

18581906093

18581906093