The Best TSA-Approved Pocket Knives & EDC - carbide insert blades

Every shop’s desire is to increase production without losing quality amidst faster machining processes. Lean manufacturing remains a common goal. Lights-out production requires inserts that last until an operator returns to change edges. A job shop gets a job that requires working with a new, difficult material. Chances are the best insert and coating to be used is not an old reliable. These are the types of situations that drive coating research forward.

“After only a few weeks of initial orientation on the new grinder, our experienced CNC operator, Chuck Best, was able to have the grinder running at maximum efficiency, and lights-out operation is now standard operating procedure for four or five nights out of the workweek,” Mini said.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

“We are starting to use coatings that incorporate rare-earth elements to try to get the coating at a higher hardness than the material being machined,” said Geisel.

Left to right: Mark Wawiorka, operator and technician; Chuck Best, CNC operator and technician; and Dan Quinn, operations manager; discuss setup and operation of Illinois Carbide Tool’s two Agathon grinding machines: a 250 PA-CNC Ultra (foreground) and a Leo Peri. Image courtesy Presage Professional Inc.

Mini explained that automotive repair shops apply the brake lathe inserts to resurface brake drums and rotors. However, the six semiautomatic grinders the company was using to make these inserts were built in the 1980s and were unable to keep up with increasing production demands because they were slow and would consistently break down. Once out of service, the troubleshooting and the search for repair parts would commence. Because of their older technology, it could take up to 3 or 4 weeks to get a grinder back up and running. “There were usually only about four out of the six running at a time,” he said.

Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpiece surfaces. When ultrasmooth surfaces and finishes on the order of microns are required, lapping and honing machines (precision grinders that run abrasives with extremely fine, uniform grits) are used. In its “finishing” role, the grinder is perhaps the most widely used machine tool. Various styles are available: bench and pedestal grinders for sharpening lathe bits and drills; surface grinders for producing square, parallel, smooth and accurate parts; cylindrical and centerless grinders; center-hole grinders; form grinders; facemill and endmill grinders; gear-cutting grinders; jig grinders; abrasive belt (backstand, swing-frame, belt-roll) grinders; tool and cutter grinders for sharpening and resharpening cutting tools; carbide grinders; hand-held die grinders; and abrasive cutoff saws.

A top layer of coating such as a colourful chrome that wears away to expose the different colour of the layer below can, by itself, provide a significant increase in productivity.

Alan holds a bachelor’s degree in journalism from Southern Illinois University Carbondale. Including his 20 years at CTE, Alan has more than 30 years of trade journalism experience.

“We did retain two of the older-technology grinders as emergency backup [machines], and the others are in storage for possible sale, or we may find someone who wants to purchase one for parts,” Mini said.

One of Crobalt’s long-term cutting tool customers primarily runs grinding machines from Agathon Machine Tools Inc., Bethel, Conn. When this customer offered Illinois Carbide Tool a used Agathon Model 250 PA-CNC Ultra grinder in 2014, the company purchased it.

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

Most of the coatings, nearly 90 per cent according to tooling manufacturers, are multilayer. The elements making up each layer, the thickness of each layer, and the order in which they are applied to the insert dictate what materials they can cut and how long they will last.

Copher said the ability of tooling manufacturers to control the crystal orientation keeps the coatings in line with each other. “Controlling the crystal orientation helps the wear resistance, the peeling resistance, and the breakdown of the coating during the machining process.”

Tooling manufacturers continually experiment with new mixes of standard coating materials and introduce new elements.

Chuck Best, CNC operator and technician at Illinois Carbide Tool, sets parameters for the Leo Peri grinder’s pick-and-place robot. Image courtesy Presage Professional Inc.

The new-generation steel turning insert grades GC4425 and GC4415 deliver improved performance in every way. Coated with second-generation Inveio® technology, they have a broad range of applications and are recommended for continuous and interrupted cuts. See how our experts worked their magic and learn what drove them to create our recently launched ISO P steel turning grades – GC4415 and GC4425.

“I’ll ask manufacturers why they are using a particular insert or coating and they say, ‘It’s just what we had.’ That’s understandable if they have only a few pieces to make, but they need to understand that all tooling manufacturers are improving technologies,” Geisel said. “A grade of coating they used 10 years ago is completely different from today’s grades which are much better.”

Mini added that the person with the most experience operating these grinders could repair about 85 percent of the problems, but obtaining parts was a challenge and not an effective use of company resources. The inserts in these grinders had to be manually loaded and unloaded by the operator into the machine’s single magazine. The operator had to manually dress the grinding wheels, check that a machine was operating properly so an insert’s IC tolerance of ±0.001" (0.0254mm) was being held while ensuring that the center screw hole was concentric to the insert’s triangular shape.

“In CVD aluminum-oxide coatings, the atoms are arranged in a hexagonal form. In the past the orientation of the coating’s building blocks were randomly arranged. Today we can control the orientation and bring a harder and tougher structure to the point of the cut. These textured coatings are 15 per cent tougher and 10 per cent harder than the old version. That means as much as 20 per cent more cutting speed or 30 per cent more tool life.”

Understandably, many of the new coatings have been developed to increase production in exotic and difficult-to-machine materials, but not all. Some new coatings boost production for established, more common materials.

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

As insert demand continued to increase, the company purchased a new Leo Peri 4-axis grinding center from Agathon earlier this year. According to Mini, the new machine is ideal for producing the company’s carbide inserts, which do not require K-lands or special features, eliminating the need for a 5-axis grinder. “A gantry loads and unloads inserts, enabling the one-shift facility to run lights-out production,” Mini said.

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

Simple robot or piece of hard automation that is capable of the simple actions of picking an object from a fixed point and placing the object at another fixed point.

Insert manufacturers, like electronic providers that continually upgrade cell phones and televisions, continually invest in research and development to make their cutting tools do a better job. The upside to not staying with the coating developed a few years ago is that new, more effective coatings add more to the bottom line. The downside, which isn’t really a downside, is that there are many more options to choose from which can make selecting the right cutting tool a bit difficult. Experts at each tooling company save the expanded options from being a problem. They will collect information on the process being used, the material being cut, and the end product being produced to be sure the right coating is selected to provide quality cuts and long-lasting performance.

Any machining process used to part metal or other material or give a workpiece a new configuration. Conventionally applies to machining operations in which a cutting tool mechanically removes material in the form of chips; applies to any process in which metal or material is removed to create new shapes. See metalforming.

Imaginary circle that touches all sides of an insert. Used to establish size. Measurements are in fractions of an inch and describe the diameter of the circle.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

“When you have older technology and you’re having problems with a grinder,” he said, “you hate to spend the money for these repairs because you’re throwing good money after bad. You start looking for solutions in the latest grinding technology.”

“Whenever we’re working with a manufacturer, we have them show us the machine to be used, specify the material, and show us the workpiece. The workpiece itself is key. Is it an easy shape or some sort of irregular shape that needs counterweights because the part might not run perfectly true? A prime example is the automotive industry because its parts might have lobes or protrusions so they have to be offset when they run. That affects the insert wear. We get a feeling for what type of cutting parameters they can operate safely and then determine the insert and coating. If you run too fast, you can risk throwing a part out of a machine and hurting the operator,” said Geisel.

Structure of the atoms within the coatings and how each coating adheres to the layer above and below also plays a large role in their effectiveness.

Iscar’s DO-TECH coating combines the CVD and PVD technologies to create a coating that improves performance when cutting cast iron for milling and turning. Geisel said, “We use a lot of titanium carbides and aluminum oxides. We also use titanium nitride—it’s a good coating to use as a top layer because it’s gold and shows the wear.”

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

Steve Geisel, senior product manager at Iscar Canada, said that there are three main categories of coatings: chemical vapour deposition (CVD), physical vapour deposition (PVD), and uncoated. CVD coatings are generally thicker and allow machining at higher surface footage, which can be good for machining carbon and alloy steels. PVD coatings are for the high-temperature alloy materials because the coatings are very thin to allow the insert to absorb heat. That quality avoids work hardening that would be caused by heat reflecting back into the cut or chip. Uncoated inserts are used for high temperature applications like titanium because many of the coatings have a titanium layer and the cutting tool needs to be harder than the material being cut.

Follow that path only if you want to lose productivity today.Insert manufacturers, like electronic providers that continually upgrade cell phones and televisions, continually invest in research and development to make their cutting tools do a better job. The upside to not staying with the coating developed a few years ago is that new, more effective coatings add more to the bottom line. The downside, which isn’t really a downside, is that there are many more options to choose from which can make selecting the right cutting tool a bit difficult. Experts at each tooling company save the expanded options from being a problem. They will collect information on the process being used, the material being cut, and the end product being produced to be sure the right coating is selected to provide quality cuts and long-lasting performance.Every shop’s desire is to increase production without losing quality amidst faster machining processes. Lean manufacturing remains a common goal. Lights-out production requires inserts that last until an operator returns to change edges. A job shop gets a job that requires working with a new, difficult material. Chances are the best insert and coating to be used is not an old reliable. These are the types of situations that drive coating research forward.John Copher, applications engineer at Sumitomo Electric Carbide Inc., said, “Part of my job is answering the engineering hotline, and almost every day someone calls and says they are working with a material we have never heard of before. As a tooling provider, we have to find out what is in the material and work with the caller to assign the grade and coating that will work best. All the old materials are still out there, but there are a lot of new materials in the aerospace, automotive, and medical fields that have caused us to adjust the technology that produces the coatings on the inserts that will cut those materials.”3 Main TypesSteve Geisel, senior product manager at Iscar Canada, said that there are three main categories of coatings: chemical vapour deposition (CVD), physical vapour deposition (PVD), and uncoated. CVD coatings are generally thicker and allow machining at higher surface footage, which can be good for machining carbon and alloy steels. PVD coatings are for the high-temperature alloy materials because the coatings are very thin to allow the insert to absorb heat. That quality avoids work hardening that would be caused by heat reflecting back into the cut or chip. Uncoated inserts are used for high temperature applications like titanium because many of the coatings have a titanium layer and the cutting tool needs to be harder than the material being cut.Advances are continually being made in all three categories.Uncoated inserts, along with the CVD and PVD coated inserts, benefit from new substrates. For coated inserts, new chemical formulas continue to make them last longer, be more efficient, and have the ability to cut established and new materials faster.Most of the coatings, nearly 90 per cent according to tooling manufacturers, are multilayer. The elements making up each layer, the thickness of each layer, and the order in which they are applied to the insert dictate what materials they can cut and how long they will last.Tooling manufacturers continually experiment with new mixes of standard coating materials and introduce new elements.“We are starting to use coatings that incorporate rare-earth elements to try to get the coating at a higher hardness than the material being machined,” said Geisel. Iscar’s grade IC6025 structure is for turning ISO M materials. Each layer of the coating and its thickness are chosen to meet a specific need. Photo courtesy of Iscar.The Shape of AtomsStructure of the atoms within the coatings and how each coating adheres to the layer above and below also plays a large role in their effectiveness.Aaron-Michael B. Eller, product manager—ISO turning and advanced materials, Seco Tools LLC, said, “In PVD aluminum titanium nitride or titanium nitride coatings, the atoms are arranged in a cubic form. During use, structural and compositional changes take place. Some are helpful but others are not. By controlling the coating process, we can encourage the good and deter the bad, resulting in increased speed capability and wear resistance.“In CVD aluminum-oxide coatings, the atoms are arranged in a hexagonal form. In the past the orientation of the coating’s building blocks were randomly arranged. Today we can control the orientation and bring a harder and tougher structure to the point of the cut. These textured coatings are 15 per cent tougher and 10 per cent harder than the old version. That means as much as 20 per cent more cutting speed or 30 per cent more tool life.”Copher said the ability of tooling manufacturers to control the crystal orientation keeps the coatings in line with each other. “Controlling the crystal orientation helps the wear resistance, the peeling resistance, and the breakdown of the coating during the machining process.”Visual AdvantageA top layer of coating such as a colourful chrome that wears away to expose the different colour of the layer below can, by itself, provide a significant increase in productivity.“We did a spot check with some of our customers. We would go to a recycle bin, grab a handful of inserts, and check the edges. They were shocked at the number of unused edges that were thrown into the bin,” said Eller. “Simply having used edges visually apparent in contrast to unused edges made it easy for operators to use all edges before tossing an insert. It creates a substantial cost savings.”Some Recent CoatingsUnderstandably, many of the new coatings have been developed to increase production in exotic and difficult-to-machine materials, but not all. Some new coatings boost production for established, more common materials.Iscar’s DO-TECH coating combines the CVD and PVD technologies to create a coating that improves performance when cutting cast iron for milling and turning. Geisel said, “We use a lot of titanium carbides and aluminum oxides. We also use titanium nitride—it’s a good coating to use as a top layer because it’s gold and shows the wear.”Sumitomo’s CVD Absotech™ Platinum coating is a multilayer aluminum oxide/titanium carbon nitride designed mainly to cut carbon steels, tool steels, and stainless steel. Copher said that the Absotech Bronze PVD coating of titanium aluminum silicon nitride is recommended for interrupted machining of stainless steel and exotic materials.Duratomic® from Seco is a CVD aluminum-oxide coating for increased edge toughness, more wear resistance, and smooth surface finishes that are cut with less friction, said Eller. When the insert does begin to wear, the chrome included in its makeup shows the worn edges. Each layer of a nanolaminate PVD coating is approximately 7 nm thick. Varying the individual layer materials and thicknesses makes it possible to adjust the hardness and thermal stability properties. Photo courtesy of Seco Tools LLC.Everything Matters“Whenever we’re working with a manufacturer, we have them show us the machine to be used, specify the material, and show us the workpiece. The workpiece itself is key. Is it an easy shape or some sort of irregular shape that needs counterweights because the part might not run perfectly true? A prime example is the automotive industry because its parts might have lobes or protrusions so they have to be offset when they run. That affects the insert wear. We get a feeling for what type of cutting parameters they can operate safely and then determine the insert and coating. If you run too fast, you can risk throwing a part out of a machine and hurting the operator,” said Geisel.“I’ll ask manufacturers why they are using a particular insert or coating and they say, ‘It’s just what we had.’ That’s understandable if they have only a few pieces to make, but they need to understand that all tooling manufacturers are improving technologies,” Geisel said. “A grade of coating they used 10 years ago is completely different from today’s grades which are much better.”Iscar Canada, 905-829-9000, www.iscar.ca Seco Tools LLC, 248- 528-5457, www.secotools.comSumitomo Electric Carbide Inc., 800-950-5205, www.sumicarbide.com Slide Show | 5 Images

Duratomic® from Seco is a CVD aluminum-oxide coating for increased edge toughness, more wear resistance, and smooth surface finishes that are cut with less friction, said Eller. When the insert does begin to wear, the chrome included in its makeup shows the worn edges.

“We did a spot check with some of our customers. We would go to a recycle bin, grab a handful of inserts, and check the edges. They were shocked at the number of unused edges that were thrown into the bin,” said Eller. “Simply having used edges visually apparent in contrast to unused edges made it easy for operators to use all edges before tossing an insert. It creates a substantial cost savings.”

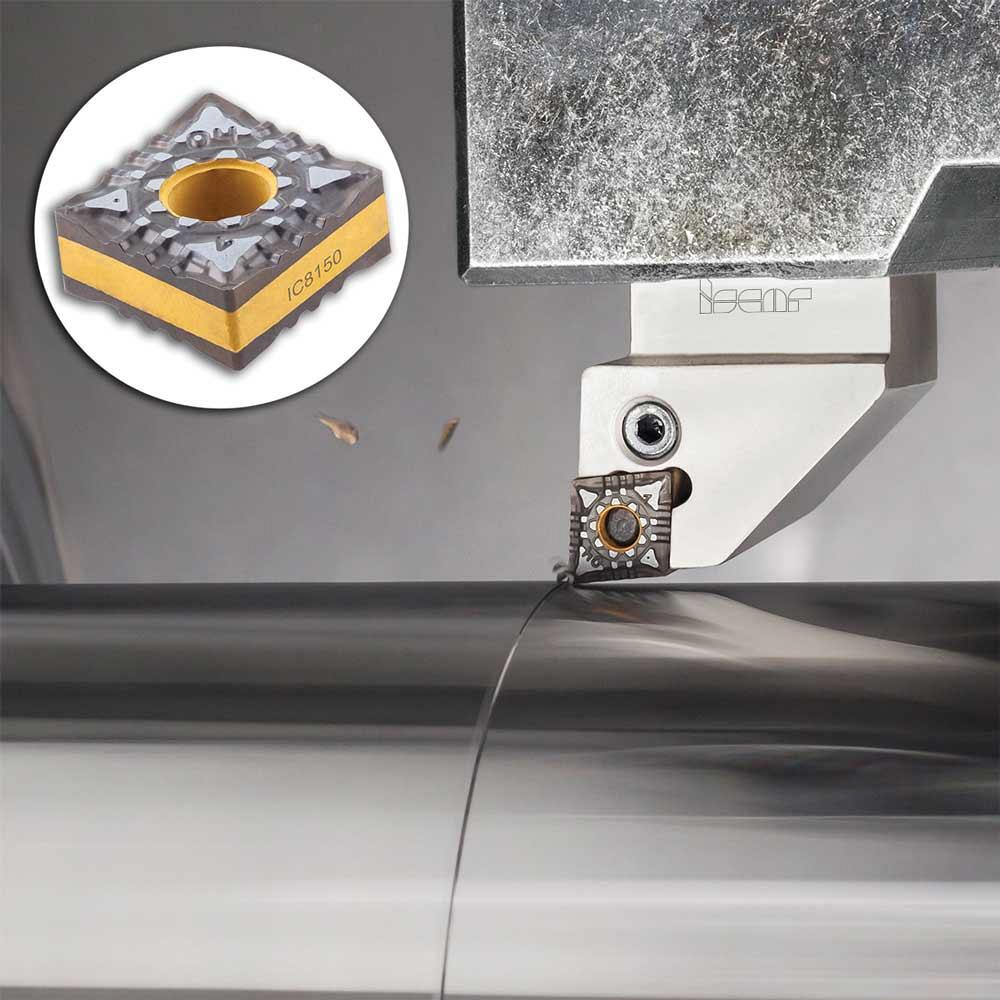

Iscar’s grade IC6025 structure is for turning ISO M materials. Each layer of the coating and its thickness are chosen to meet a specific need. Photo courtesy of Iscar.

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

“It was a major initial step in enabling us to get our production up to where it needed to be at a critical time,” Mini said.

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

Each layer of a nanolaminate PVD coating is approximately 7 nm thick. Varying the individual layer materials and thicknesses makes it possible to adjust the hardness and thermal stability properties. Photo courtesy of Seco Tools LLC.

The Waukegan, Ill., manufacturer has two operating divisions: Brake Drum Tool Co., which produces inserts, tool bodies and cutting tools for the automotive industry, such as cylinder boring tools; and Crobalt, which manufactures a high-cobalt cast alloy used in metalcutting and woodworking tools and wear parts.

Sumitomo’s CVD Absotech™ Platinum coating is a multilayer aluminum oxide/titanium carbon nitride designed mainly to cut carbon steels, tool steels, and stainless steel. Copher said that the Absotech Bronze PVD coating of titanium aluminum silicon nitride is recommended for interrupted machining of stainless steel and exotic materials.

Easily access valuable industry resources now with full access to the digital edition of Canadian Metalworking.

Sue Roberts, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. A metalworking industry veteran, she has contributed to marketing communications efforts and written B2B articles for the metal forming and fabricating, agriculture, food, financial, and regional tourism industries.

The new Agathon grinder has totally replaced the semiautomatic grinders. Improvement in the quality and precision of the insert’s IC grind means rejects are virtually eliminated, according to Mini. Should a problem occur, the machine will automatically cease grinding and go into a standby mode.

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

The grinder interfaces with up to six standard pallets and these pallets can be purchased for specific sizes of inserts. Complete automation of the periphery grinding process by the new grinder achieves insert quality that was previously unobtainable by the older technology, according to Mini. “We currently are not producing on Sundays, but we certainly could if the need would arise.”

END USER: lllinois Carbide Tool Co. Inc., (800) 323-2414, www.crobaltusa.com, www.brakedrumtool.com. SOLUTION PROVIDER: Agathon Machine Tools Inc., (203) 730-8741, www.agathon.com. CHALLENGE: Keep up with increasing production demands for carbide brake lathe inserts. SOLUTION: A 4-axis grinding machine that enables lights-out production.

John Copher, applications engineer at Sumitomo Electric Carbide Inc., said, “Part of my job is answering the engineering hotline, and almost every day someone calls and says they are working with a material we have never heard of before. As a tooling provider, we have to find out what is in the material and work with the caller to assign the grade and coating that will work best. All the old materials are still out there, but there are a lot of new materials in the aerospace, automotive, and medical fields that have caused us to adjust the technology that produces the coatings on the inserts that will cut those materials.”

The new Agathon Leo Peri grinder has changed the entire production dynamic at Illinois Carbide Tool and its divisions, Mini said. “In addition to carbide indexable insert grinding, we are utilizing the new Agathon to grind our cast alloy woodworking inserts for our Crobalt customers. This is something we could not have done on the older-technology grinders.”

Uncoated inserts, along with the CVD and PVD coated inserts, benefit from new substrates. For coated inserts, new chemical formulas continue to make them last longer, be more efficient, and have the ability to cut established and new materials faster.

More production sometimes requires fewer machines. As orders for its carbide brake lathe inserts increased at least 20 percent during the last 18 months, Illinois Carbide Tool Co. Inc. transitioned from six grinding machines with obsolete technology to a newer CNC grinder and a brand-new CNC grinder, said Mike Mini, company owner and manager.

Aaron-Michael B. Eller, product manager—ISO turning and advanced materials, Seco Tools LLC, said, “In PVD aluminum titanium nitride or titanium nitride coatings, the atoms are arranged in a cubic form. During use, structural and compositional changes take place. Some are helpful but others are not. By controlling the coating process, we can encourage the good and deter the bad, resulting in increased speed capability and wear resistance.

Coatings like Sumitomo’s CVD Absotech Platinum are designed to increase cutting speeds and improve cuts in carbon steels, tool steels, and stainless steels. Photo courtesy of Sumitomo Electric Carbide Inc.

18581906093

18581906093