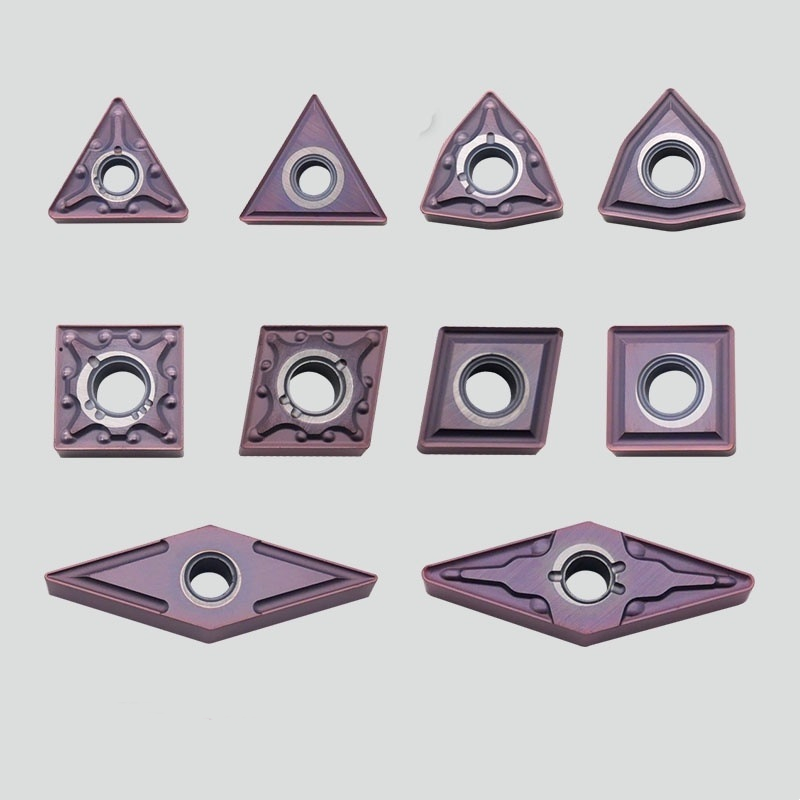

10Pcs CNC Insert Cutter Tools,Carbide Turning ... - cnc cutting tool insert

Reason: improper parameter setting, improper selection of blade material, poor rigidity of workpiece, unstable blade clamping. Action: Check the machining parameters, such as reducing the line speed and changing to a higher wear-resistant insert.

Influence: sudden and unpredictable occurrence, resulting in scrapped tool holder material or defective workpiece and scrapped. Cause: The processing parameters are set incorrectly, and the vibration tool workpiece or blade is not installed in place.

On this bit, you will never need to get your cutting edges professionally sharpened, thanks to the 4 sided replaceable inserts. Simply loosen the screw, rotate 1/4 turn, & retighten screw for a brand new, razor sharp cutting edge.

2. The overall hardness of the blade is stronger, the cutting edge is sharper and more wear-resistant, and the service life is longer.

Measures: Set reasonable processing parameters, reduce the feed amount and reduce the chips to select the corresponding processing inserts.

Influence: The size of the protruding workpiece is inconsistent, the surface finish is poor, and the surface of the workpiece is attached with fluff or burrs. Reason: The cutting speed is too low, the feed is too low and the blade is not sharp enough.

18581906093

18581906093