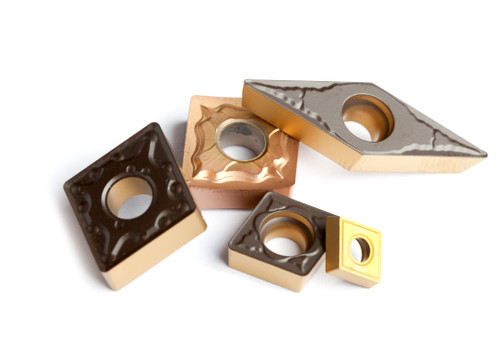

CNC turning: Insert nomenclature details - insert for cnc machine

1. DTF model is designed specially finishing machining for quenched steel up to 60HRC 2. DPM is for Semi-Finishing chip-breaker work for steel. 3. DMA special chip breaker designed to work for both steel and stainless steel 4. DGH Suitable for semi-finishing,excellent with interrupted cutting,margin and negative chamfer design ,good for high feed cutting on alloy steel

the cutting force small, the chip breaking range is wide, and the edge edge is sharper than epmk. Therefore,even when cutting

2. CVD coating : High Co content and fine WC grain substrate ,gives wonderful cutting edge strength,combines with good thermal stability silicon coating ,it has very small coefficient of friction ,and good nano hardness

DPMK Negative insert chipbreaker,the special three-dimensional groove design of double rake angle and variable edge width makes

alloy steel with high viscosity, it can obtain good surface quality; it also has good performance in the case of uneven processing

.DMA special chip breaker designed to keep both sharp cutting edge and good impact resistance, which can efficiently avoid accumulating and suitable for semi-finishing ISO M and ISO P20-P30 steel material.

18581906093

18581906093