Cutting inserts - types, designations, purpose, colors ... - cnc machine insert supplier

The Seco comprehensive grade and geometry range covers all material groups and allows you to achieve improved material removal rates, tool life and surface finishes.

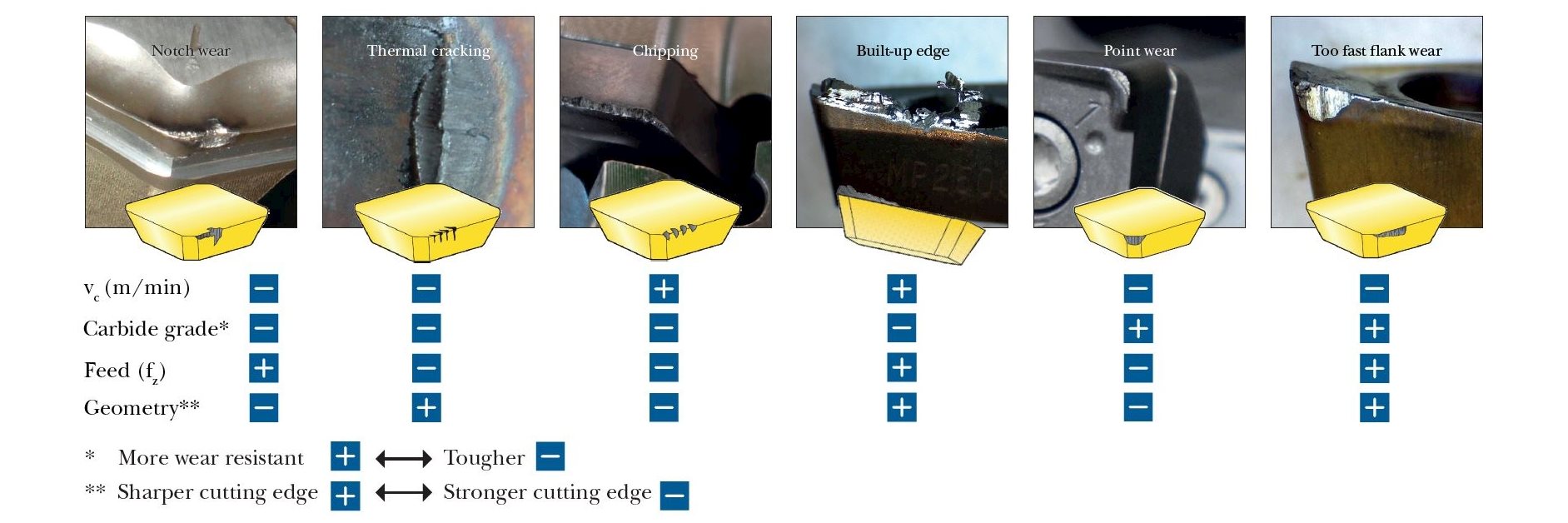

Tougher grades also have fewer issues with the thermal cracking and notch wear that can be challenges in milling. The drawback with tough grades is that they tend toward higher flank, crater wear and plastic deformation, which require an adjustment toward the harder, more wear-resistant grades shown at the top of the chart.

For historic reasons, many grades do not adopt the new nomenclature. These legacy grades will be updated as new generations launch.

For each product family, Seco provides a first choice of grade and geometry based on material group. This reduces complexity and provides a starting point for further optimization. The digital catalog and Seco Suggest online application provide this information.

To submit forms on this page, you need to consent to the transfer of data and storage of third-party cookies by Google. With your consent, reCAPTCHA, a Google service to avoid spam messages via contact forms, will be embedded. This service allows us to provide our customers with a safe way to contact us via online forms. At the same time, the service prevents spam bots from compromising our services. After you gave your permission, you might be asked to answer a security prompt to send the form. If you do not consent, unfortunately you cannot use the form. Please contact us in a different way.

In addition to grade, the insert geometry has a tremendous impact on the machining process and the way the grade behaves and wears.

Conversely, extreme thermal and abrasive conditions will adversely impact tool life on an insert with a tough grade and heavily protected geometry.

To view Vimeo contents on this website, you need to consent to the transfer of data and storage of third-party cookies by Vimeo.. This allows us to improve your user experience and to make our website better and more interesting. Without your consent, no data will be transferred to Vimeo. However, you will also not be able to use the Vimdeo services on this website.

Understanding the diversity of Seco milling grades’ strengths and alignments will help guide you to the best choice for the material you are machining.

To view YouTube contents on this website, you need to consent to the transfer of data and storage of third-party cookies by YouTube (Google). This allows us to improve your user experience and to make our website better and more interesting. Without your consent, no data will be transferred to YouTube. However, you will also not be able to use the YouTube services on this website.

From top to bottom, the chart arranges grades by increasing toughness, with the toughest grades indicated at the bottom.

To send data to Brevo, you need to consent to the transfer of data and storage of third-party cookies by Brevo. This allows us to improve your user experience and to make our website better and more interesting.

Newly launched grades follow a simple nomenclature format that allows you to quickly understand grade characteristics and suitable working ranges.

Supporting inserts of different shapes, sizes and thicknesses, we developed each of these solutions with the same goal in mind: to optimize your milling operations for increased productivity.

Our General Grade Mapping chart below will help optimize your application with the appropriate combination of grade and geometry.

Would you like to see these contents? Activate the desired contents for one session only or allow the website to remember these settings. Once you have given your consent, the third-party data can be loaded. For this, third-party cookies might be stored on your device. You can change these settings at any time (fingerprint icon in the bottom left corner). For further details, please see the Privacy notice.

Click on the workpiece material to find the most suitable Seco milling grade and geometry combinations for your application.

By selecting "Accept all", you give us permission to use the following services on our website: YouTube, Vimeo, ReCaptcha, Google Analytics, Google Ads, Google Tag Manager, dash.bar, Brevo. You can change the settings at any time (fingerprint icon in the bottom left corner). For further details, please see Individual configuration and our Privacy notice.

This chart provides an overview of most milling grades in the context of workpiece material. The chart also shows basic grade toughness, as well as geometric characteristics for sharpness and strength. Based on workpiece material, you can identify suitable grade/geometry combinations as a first orientation. You can also see the various types of materials a grade can machine as well as suitable geometry matches.

Tougher grades can handle higher chip loads and enable the use of sharper geometries, work with interrupted cuts or vibrations, heterogenous workpiece conditions, and machine in inclusions with less edge chipping and disruption.

This is an advertising service. This service can be used to display personalized or non-personalized advertising to users. With Google Ads Conversion Tracking, we can measure our advertising success in the Google advertising network. We place advertisements in the Google advertising network so that our offers can be found more easily. We try to optimize our advertising as much as possible. Also to keep advertising costs as low as possible. This is reflected in our prices.

End mill with indexable inserts The end mill consisting of tool steel is equipped with carbide indexable inserts. The indexable inserts are standardized and can be easily exchanged. Application: Aluminum, plastic, wood Technical data Indexable inserts APGT1135 - solid carbide Basic body Tool steel Scope of delivery: End mill incl. Indexable inserts and tools Diameter Shank Cutting length / total length Indexable inserts Length B 10 10 8 / 70 APGT1135 12 12 8 / 70 APGT1135 16 16 8 / 80 APGT1135

Anything is possible when it comes to machining with our broad selection of general insert milling grades and geometries.Supporting inserts of different shapes, sizes and thicknesses, we developed each of these solutions with the same goal in mind: to optimize your milling operations for increased productivity.The Seco comprehensive grade and geometry range covers all material groups and allows you to achieve improved material removal rates, tool life and surface finishes.For enhanced performance, many of our variants are coated with CVD or PVD layers on the carbide substrate.Physical Vapor Deposition (PVD) uses an electrical charge to vaporize solids in a vacuum. The vapor adds up to a 4-5 µm coating to add hardness, reduce friction and improve wear resistance for increased speeds and feeds.Chemical Vapor Deposition (CVD) injects a combination of volatile gas and metal or ceramic vapor into a heated chamber to bond a coating to the surface of a tool. The resulting 7 µm or thicker coating provides resistance to wear as well as heat.Uncoated inserts are more suited to machine non-ferrous material such as aluminium alloys. When you know the name, you know the gradeBefore you dive into the strength and the alignment of our Seco milling grades, understand the nomenclature involved.Newly launched grades follow a simple nomenclature format that allows you to quickly understand grade characteristics and suitable working ranges.For historic reasons, many grades do not adopt the new nomenclature. These legacy grades will be updated as new generations launch.Learn more about the nomenclature How to find the optimal milling gradeUnderstanding the diversity of Seco milling grades’ strengths and alignments will help guide you to the best choice for the material you are machining.Our General Grade Mapping chart below will help optimize your application with the appropriate combination of grade and geometry.This chart provides an overview of most milling grades in the context of workpiece material. The chart also shows basic grade toughness, as well as geometric characteristics for sharpness and strength. Based on workpiece material, you can identify suitable grade/geometry combinations as a first orientation. You can also see the various types of materials a grade can machine as well as suitable geometry matches.From top to bottom, the chart arranges grades by increasing toughness, with the toughest grades indicated at the bottom.Tougher grades can handle higher chip loads and enable the use of sharper geometries, work with interrupted cuts or vibrations, heterogenous workpiece conditions, and machine in inclusions with less edge chipping and disruption.Tougher grades also have fewer issues with the thermal cracking and notch wear that can be challenges in milling. The drawback with tough grades is that they tend toward higher flank, crater wear and plastic deformation, which require an adjustment toward the harder, more wear-resistant grades shown at the top of the chart.Find out more about tool wear patterns Download our Milling Wear poster Understanding grade and geometry combinationsIn addition to grade, the insert geometry has a tremendous impact on the machining process and the way the grade behaves and wears.A hard grade combined with a too-sharp geometry can easily chip and fracture during extreme interrupted cuts or when machining in inclusions.Conversely, extreme thermal and abrasive conditions will adversely impact tool life on an insert with a tough grade and heavily protected geometry.Optimizing your tool life and application is always a balance between insert grade and geometry.For each product family, Seco provides a first choice of grade and geometry based on material group. This reduces complexity and provides a starting point for further optimization. The digital catalog and Seco Suggest online application provide this information.Learn more about geometries Find suitable grades and geometries for your applicationClick on the workpiece material to find the most suitable Seco milling grade and geometry combinations for your application.Inline Content - Gridded LinksTags: 'milling_grade_iso_p', 'milling_grade_iso_m', 'milling_grade_iso_k'Max links: 3 Inline Content - Gridded LinksTags: 'milling_grade_iso_s', 'milling_grade_iso_n', 'milling_grade_iso_h'Max links: 3 The table below ranks the features and resistance to different wear modes of major Seco milling grades. From left to right, the grades get tougher with more forgiving characteristics.CVD Milling Grade MappingCVD Grade OfferingMK1500MP1501MP2501MS2500MP3501MM4500Mechanical ShockFracture Resistance********************Thermal Shock Resistance*****************Thermal Wear Resistance**********************Abrasive Wear Resistance********************Crater Resistance********************Material StrengthKP, K, HP, M, KS, M, PP, M, SM, S, P PVD Milling Grade MappingPVD Grade OfferingMH1000F15MMK2050MP3000F30MMS2050F40MMP2050Mechanical ShockFracture Resistance********************Thermal Shock Resistance*******************Thermal Wear Resistance******************Abrasive Wear Resistance*********************Crater Resistance*****************Material StrengthH, KK, P, HP, H, MS, M, PP, M, SP, M, S Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

A hard grade combined with a too-sharp geometry can easily chip and fracture during extreme interrupted cuts or when machining in inclusions.

This is a tag management system. The Google Tag Manager allows tags to be integrated centrally via a user interface. Tags are small sections of code that can track activities. Script codes from other tools are integrated via the Google Tag Manager. The Tag Manager makes it possible to control when a specific tag is triggered.

The settings you specify here are stored in the "local storage" of your device. The settings will be remembered for the next time you visit our online shop. You can change these settings at any time (fingerprint icon in the bottom left corner).For more information on cookie lifetime and required essential cookies, please see the Privacy notice.

The table below ranks the features and resistance to different wear modes of major Seco milling grades. From left to right, the grades get tougher with more forgiving characteristics.

This is a web analysis service. It allows the user to measure advertising return on investment (ROI) and track user behavior. Data collected: anonymized IP address, date and time of visit, usage data, click path, app updates, browser information, device information, JavaScript support, pages visited, referrer URL, location information, purchase activity, widget interactions.

18581906093

18581906093