Cutting inserts - types, designations, purpose, colors ... - grooving insert designation

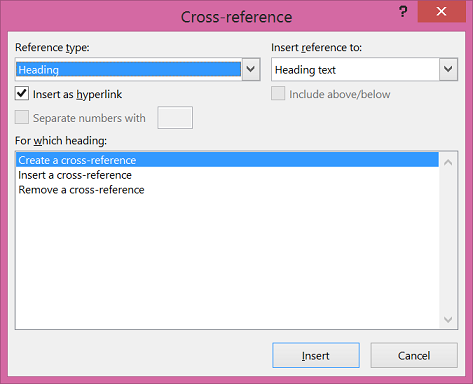

If the Include above/below check box is available, check it to include specify the relative position of the referenced item.

It is composed of WC and Co. It has high bending strength, toughness, good thermal conductivity, but poor heat resistance and wear resistance. It is mainly used for processing cast iron and non-ferrous metals. Fine-grained YG cemented carbide (such as YG3X, YG6X), when the cobalt content is the same, its hardness and wear resistance are higher than YG3, YG6, strength and toughness are slightly worse, suitable for processing hard cast iron, austenitic stainless steel , heat-resistant alloy, hard bronze, etc.

As a professional supplier of cabride insert, we are happy to help you. If you have any more questions, please contact us immediately.

As the hardness and melting point of TiC are higher than that of WC, compared with YG, its hardness, wear resistance, red hardness are increased, the bonding temperature is high, the oxidation resistance is strong, and it will generate TiO2 at high temperature, which can reduce the adhesion. But it has poor thermal conductivity and low bending strength, so it is suitable for processing tough materials such as steel.

Adding TaC (NbC) on the basis of YT hard alloy improves the bending strength, impact toughness, high temperature hardness, oxygen resistance and wear resistance. It can process steel, cast iron and non-ferrous metals. Therefore, it is often called general-purpose cemented carbide (also known as universal cemented carbide).

In the M type, the range is relatively small. The stainless steel materials include ferrite/martensite, and the cast steel materials include martensite and austenite.

Cross-references are inserted into your document as fields. A field is a set of information that instructs Word to insert text, graphics, page numbers, and other material into a document automatically. For example, the DATE field inserts the current date. The advantage of using fields is that the content being inserted--date, page number, graphics, etc.--gets updated for you whenever there's a change. For example, if you're writing a document over a period of days, the date will change each day when you open and save the document. Similarly, if you update a graphic that's stored elsewhere but referenced in the field, the update will get picked up automatically without you having to re-insert the graphic.

In the document, type the text that begins the cross-reference. For example, "See Figure 2 for an explanation of the upward trend."

The hardness of cemented carbide in the K-class cutting range includes ferrite, pearlite gray cast iron, nodular cast iron, pearlite ferritic malleable cast iron.

Type S refers to iron-based high-temperature alloys. Superalloy materials include nickel-based, cobalt-based, titanium-based, and titanium alloys.

If you want to cross-reference items that reside in a separate document but don't want to use hyperlinks, you'll have to first combine the documents into one master document and then insert the cross-references. A master document is a container for a set of separate files (or subdocuments). You can use a master document to set up and manage a multi-part document, such as a book with several chapters.

A cross-reference allows you to link to other parts of the same document. For example, you might use a cross-reference to link to a chart or graphic that appears elsewhere in the document. The cross-reference appears as a link that takes the reader to the referenced item.

In the Insert reference to box, click the information you want inserted in the document. Choices depend on what you chose in step 3.

Class H refers to the cutting hardness of the blade in the range of hardened hardened steel, cast chilled cast iron, hardened cast iron, etc.

In carbide insert, the cutting range of P products refers to carbon steel and cast steel, including 0.25-0.25% C quenching and quenching and tempering. Free-cutting steel includes annealing and quenching and tempering. Low-carbon alloy steel contains less than 5%, high-carbon alloy steel cast iron and tool steel including annealing and quenching and tempering series.

If you've inserted a cross-reference and it looks similar to {REF _Ref249586 \* MERGEFORMAT}, then Word is displaying field codes instead of field results. When you print the document or hide field codes, the field results replace the field codes. To see the field results instead of field codes, press ALT+F9, or right-click the field code, and then click Toggle Field Codes on the shortcut menu.

You can't cross-reference something that doesn't exist, so be sure to create the chart, heading, page number, etc., before you try to link to it. When you insert the cross-reference, you'll see a dialog box that lists everything that's available to link to. Here's an example.

Suppose someone asks you what P, M, K, N, S, and H represent in carbide insert? What is its cutting hardness? do you know? How would you answer this question? If you don’t know, just follow me to find out.

Class N refers to uncured aluminum, refined alloys, cast alloys, and copper alloys include free-cutting steel, brass, and electrolytic copper.

In the Reference type box, click the drop-down list to pick what you want to link to. The list of what's available depends on the type of item (heading, page number, etc.) you're linking to.

Commonly used cemented carbide has WC as its main component. According to whether other carbides are added, it can be divided into the following three categories:

(3) Tungsten Titanium Tantalum Cobalt (WC+TiC+TaC+Co)) Cemented Carbide (YWYS) "Mainly process difficult-to-process materials such as heat-resistant steel, high manganese steel, stainless steel, etc."

18581906093

18581906093