Cutting inserts - types, designations, purpose, colors ... - milling carbide insert designation

The A&M Industrial Metalworking Team has identified the most common end mill problems, along with their likely cause and solution. Utilize the handy chart below to...

Insert cratering is caused by excessive heat. In addition, cratering can occur when hard micro inclusions in the workpiece cut into the insert. Also, small pieces of the coating can break off and cut into the insert. The cobalt then wears out and the carbide grains no longer have any adhesion, and therefore break off.

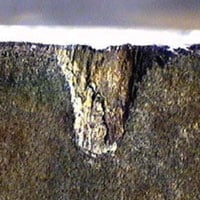

Rapid change in thermal loads can cause thermal cracking. Temperature difference between warm and cold zones causes thermal stress which leads to cracking of the insert.

Use a tougher grade with higher cobalt content.Reduce the risk of vibrations.Select a larger nose radius.Increase cutting speed.

Learn the cause and solution to the most common insert wear problems. Utilize the Tungaloy Insert Wear Chart to quickly identify the root cause of carbide insert wear problems including built up edge, chipping, cratering, edge deformation, flank wear, notching, and thermal cracking. Utilize the expert recommendations provided to fix the issue and optimize your machining process. Learn how to tackle the most common insert wear problems and keep your Tungaloy inserts performing at their best.

Use heat resistant grades.Use an abundant supply of coolant OR do not use coolant.Reduce cutting speed.Use positive rake tools.

This product works with these LittleMachineShop.com products: 3698 Insert, TCMW-321 HSS 2381 Insert, TPGH-32.51 Carbide 5644 Insert, TPGH-322 Carbide 2694 Screw, Insert Retaining, M4x10 5554 Torx Wrench, T-15 4846 Torx Wrench, T-15, Wiha

Heavy feeds and high cutting speeds can cause edge deformation. The heat softens the insert structure, causing the cobalt to soften and the insert becomes deformed.

Excessive heat. Hard micro inclusions in the workpiece cut into the insert. Small pieces of the coating break off and also cut into the insert. The cobalt then wears out and the carbide grains no longer have any adhesion and therefore break off.

Our metalworking experts team up with the professionals at Tungaloy to deliver unparalleled expertise and recommendations.

Understanding how to troubleshoot some typical band sawing challenges can be helpful for new and experienced band saw operators alike. Although cutting issues will vary...

Use harder, more wear resistant grade.Reduce your cutting speed.Reduce feed rate.Use larger corner radius for shallow cuts.

Style E Neutral threading tool with 60° included angle Style BL left hand tool with a 15° lead angle Style AL left hand tool Carbide inserts are TPGH-32.51.

Style E Neutral threading tool with 60° included angle Style BL left hand tool with a 15° lead angle Style AL left hand tool Carbide inserts are TPGH-32.51.

Style BR right hand tool with a 15° lead angle Style E Neutral threading tool with 60° included angle Style BL left hand tool with a 15° lead angle Style AL left hand tool Carbide inserts are TPGH-32.51.

Style AR right hand tool Style BR right hand tool with a 15° lead angle Style E Neutral threading tool with 60° included angle Style BL left hand tool with a 15° lead angle Style AL left hand tool Carbide inserts are TPGH-32.51.

Style AR right hand tool Style BR right hand tool with a 15° lead angle Style E Neutral threading tool with 60° included angle Style BL left hand tool with a 15° lead angle Style AL left hand tool Carbide inserts are TPGH-32.51.

Style BR right hand tool with a 15° lead angle Style E Neutral threading tool with 60° included angle Style BL left hand tool with a 15° lead angle Style AL left hand tool Carbide inserts are TPGH-32.51.

See Tungaloy's latest innovations in action, including the Tungaloy AddForce line! A&M Industrial's YouTube channel features hundreds of application videos and product introductions, plus exclusive videos you can only watch at A&M!

18581906093

18581906093