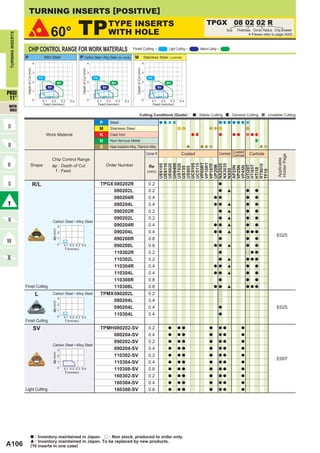

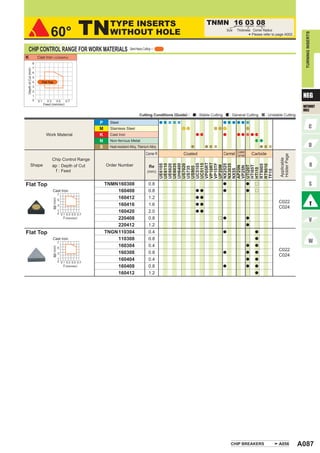

Insert nose radius chart- for feed rate selection in turning - cnc lathe insert chart

23 Olive Road, PenrosePO Box 112114 Auckland 1642Phone: (09) 525-8900Freephone: 0800 4 TOOLSEmail: sales@tradetools.co.nz

Shop at your convenience across our huge range of first-class tooling for something specific or just your normal stock orders. It has never been easier to access product from the most trusted name in the NZ Engineering scene.

CBN300: Brazed layer, Ten Edges (single sided). Composition: 90% CBN content grade with an average grain size of 22 µm and a Al ceramic binder. Coating: No coating • For medium rough machining of hardened steel (ap = 0,5–1,0 mm). • For finishing and roughing of pearlitic and white/chilled cast iron. • For finishing of sintered iron. • For roughing and finishing of powder metal (iron). Polycrystalline Cubic Boron Nitride (PCBN) is a material which is sintered at extremely high pressure and high temperature into a wear-resistant material with properties close to those of diamond. Due to the hot hardness, oxidation resistance and fracture toughness of the material, inserts made of PCBN have excellent edge strength and long tool life in machining operations on hard ferrous materials and pearlitic grey cast iron. Secomax PCBN inserts are suitable for machining: • Hardened steel (including hard-facing alloys) • Pearlitic grey cast iron • Chilled and white cast iron • Manganese steel • Cemented carbide • Valve seat materials • Powder Metallurgy (PM) alloys • Nickel-based superalloys e.g. Inconel 718

We also have FREE SHIPPING on orders above $100 to any address in mainland New Zealand. However, items weighing above 45KG & deliveries to island addresses (Chatham’s, Stewart, Great barrier & Waiheke etc) and Rural delivery are exempt from the offer and will attract additional shipping rates (Please contact customer services for exact cost).

CBN200: Brazed Layer, Ten Edges (single sided). Composition: 85% cBN content grade with an average grain size of 2 µm and a Co-W-Al ceramic binder. Coating: No coating • For medium rough machining of hardened steel (ap = 0,5–1,0 mm). • For finishing and roughing of pearlitic and white/chilled cast iron. • For finishing of sintered iron. • For roughing and finishing of powder metal (iron). Polycrystalline Cubic Boron Nitride (PCBN) is a material which is sintered at extremely high pressure and high temperature into a wear-resistant material with properties close to those of diamond. Due to the hot hardness, oxidation resistance and fracture toughness of the material, inserts made of PCBN have excellent edge strength and long tool life in machining operations on hard ferrous materials and pearlitic grey cast iron. Secomax PCBN inserts are suitable for machining: • Hardened steel (including hard-facing alloys) • Pearlitic grey cast iron • Chilled and white cast iron • Manganese steel • Cemented carbide • Valve seat materials • Powder Metallurgy (PM) alloys • Nickel-based superalloys e.g. Inconel 718

Most products will be shipped to your nominated address by tracked courier. Our preferred courier company is New Zealand Couriers, however, we may have to use other freight companies from time to time based on an items size, configuration or dangerous goods requirements. Trade Tools cannot be held accountable for delivery times once items have been dispatched.

CBN200: Brazed Layer, Ten Edges (single sided). Composition: 85% cBN content grade with an average grain size of 2 µm and a Co-W-Al ceramic binder. Coating: No coating • For medium rough machining of hardened steel (ap = 0,5–1,0 mm). • For finishing and roughing of pearlitic and white/chilled cast iron. • For finishing of sintered iron. • For roughing and finishing of powder metal (iron). Polycrystalline Cubic Boron Nitride (PCBN) is a material which is sintered at extremely high pressure and high temperature into a wear-resistant material with properties close to those of diamond. Due to the hot hardness, oxidation resistance and fracture toughness of the material, inserts made of PCBN have excellent edge strength and long tool life in machining operations on hard ferrous materials and pearlitic grey cast iron. Secomax PCBN inserts are suitable for machining: • Hardened steel (including hard-facing alloys) • Pearlitic grey cast iron • Chilled and white cast iron • Manganese steel • Cemented carbide • Valve seat materials • Powder Metallurgy (PM) alloys • Nickel-based superalloys e.g. Inconel 718

CBN300: Brazed layer, Ten Edges (single sided). Composition: 90% CBN content grade with an average grain size of 22 µm and a Al ceramic binder. Coating: No coating • For medium rough machining of hardened steel (ap = 0,5–1,0 mm). • For finishing and roughing of pearlitic and white/chilled cast iron. • For finishing of sintered iron. • For roughing and finishing of powder metal (iron). Polycrystalline Cubic Boron Nitride (PCBN) is a material which is sintered at extremely high pressure and high temperature into a wear-resistant material with properties close to those of diamond. Due to the hot hardness, oxidation resistance and fracture toughness of the material, inserts made of PCBN have excellent edge strength and long tool life in machining operations on hard ferrous materials and pearlitic grey cast iron. Secomax PCBN inserts are suitable for machining: • Hardened steel (including hard-facing alloys) • Pearlitic grey cast iron • Chilled and white cast iron • Manganese steel • Cemented carbide • Valve seat materials • Powder Metallurgy (PM) alloys • Nickel-based superalloys e.g. Inconel 718

Our FREE SHIPPING offer applies to the noted locations within New Zealand only. For international delivery, please Contact Us to discuss your requirements.

CBN200: Brazed Layer, Ten Edges (single sided). Composition: 85% cBN content grade with an average grain size of 2 µm and a Co-W-Al ceramic binder. Coating: No coating • For medium rough machining of hardened steel (ap = 0,5–1,0 mm). • For finishing and roughing of pearlitic and white/chilled cast iron. • For finishing of sintered iron. • For roughing and finishing of powder metal (iron). Polycrystalline Cubic Boron Nitride (PCBN) is a material which is sintered at extremely high pressure and high temperature into a wear-resistant material with properties close to those of diamond. Due to the hot hardness, oxidation resistance and fracture toughness of the material, inserts made of PCBN have excellent edge strength and long tool life in machining operations on hard ferrous materials and pearlitic grey cast iron. Secomax PCBN inserts are suitable for machining: • Hardened steel (including hard-facing alloys) • Pearlitic grey cast iron • Chilled and white cast iron • Manganese steel • Cemented carbide • Valve seat materials • Powder Metallurgy (PM) alloys • Nickel-based superalloys e.g. Inconel 718

CBN300: Brazed layer, Ten Edges (single sided). Composition: 90% CBN content grade with an average grain size of 22 µm and a Al ceramic binder. Coating: No coating • For medium rough machining of hardened steel (ap = 0,5–1,0 mm). • For finishing and roughing of pearlitic and white/chilled cast iron. • For finishing of sintered iron. • For roughing and finishing of powder metal (iron). Polycrystalline Cubic Boron Nitride (PCBN) is a material which is sintered at extremely high pressure and high temperature into a wear-resistant material with properties close to those of diamond. Due to the hot hardness, oxidation resistance and fracture toughness of the material, inserts made of PCBN have excellent edge strength and long tool life in machining operations on hard ferrous materials and pearlitic grey cast iron. Secomax PCBN inserts are suitable for machining: • Hardened steel (including hard-facing alloys) • Pearlitic grey cast iron • Chilled and white cast iron • Manganese steel • Cemented carbide • Valve seat materials • Powder Metallurgy (PM) alloys • Nickel-based superalloys e.g. Inconel 718

CBN300: Brazed layer, Ten Edges (single sided). Composition: 90% CBN content grade with an average grain size of 22 µm and a Al ceramic binder. Coating: No coating • For medium rough machining of hardened steel (ap = 0,5–1,0 mm). • For finishing and roughing of pearlitic and white/chilled cast iron. • For finishing of sintered iron. • For roughing and finishing of powder metal (iron). Polycrystalline Cubic Boron Nitride (PCBN) is a material which is sintered at extremely high pressure and high temperature into a wear-resistant material with properties close to those of diamond. Due to the hot hardness, oxidation resistance and fracture toughness of the material, inserts made of PCBN have excellent edge strength and long tool life in machining operations on hard ferrous materials and pearlitic grey cast iron. Secomax PCBN inserts are suitable for machining: • Hardened steel (including hard-facing alloys) • Pearlitic grey cast iron • Chilled and white cast iron • Manganese steel • Cemented carbide • Valve seat materials • Powder Metallurgy (PM) alloys • Nickel-based superalloys e.g. Inconel 718

Trade Tools will use all reasonable endeavors to quickly ship your orders. In most cases orders are shipped overnight, however, factors like weekends, public holidays, rural delivery or shipment size can create delays outside of our control.

This document provides information on how to read turning insert standards. It is organized by insert shape and includes details like grade, application, recommended work materials, and cutting conditions. Graphs show recommended chip breakers and cutting ranges for different materials and applications, from finish to heavy cutting. Inserts are shown in order of negative or positive type, with breakers arranged from finish to heavy cutting. Specifications for individual inserts include size, grade, recommended uses and cutting conditions.Read less

18581906093

18581906093