12 answers regarding today's cutting tools - osg carbide end mills

Owing to the current global shortage in semiconductors, NS Tool has recently gained a foothold in the semiconductor manufacturing industry and is looking to expand into the Internet of Things. The key applications for their tools, however, remain the smartphone and automotive industries. With the Japanese government phasing out the sale of internal combustion engines by 2035, the latter in particular is experiencing an unprecedented phase of transition.

Pressed on the company’s international strategy more broadly, Mr. Goto is realistic enough to know that as a manufacturer of small parts, NS Tool cannot expect to be successful everywhere: “we need to carefully choose the markets in which we can thrive… zeroing in on those where precision tools are required, such as that for Swiss watches.”

To regain access, please make sure that cookies and JavaScript are enabled before reloading the page.

As you were browsing something about your browser made us think you were a bot. There are a few reasons this might happen:

Here, too, NS Tool appears well placed to respond. Huge investments are being made into both electric and fuel cell vehicles (FCVs), and with investment comes opportunity. CBN end mills developed by the firm are already being used to create fuel cell separators for FCVs, the application of which is widespread, encompassing trains, ships and trucks as well as vehicles that are automated with fixed tracks and stations.

“More than ten years ago, when we created [the Micro Edge end mill], some said there was no market for it. But without tools, things cannot be made. Back then, we standardized the product and added it to our catalog, meaning when electronics companies reduced the size of their parts, it was readily available for use.”

Looking to the near future, the second half of 2022 provides several key opportunities. Already present in Hong-Kong and mainland China, NS Tool opened a new subsidiary in the U.S.A. this year to increase stock availability and provide technical support, through which the company will target medical equipment and the expanding high-precision machining industry in the American market. In September, meanwhile, the International Manufacturing Technology Show (IMTS) offers the chance to forge new relationships with global clients.

Though the company’s longevity can be partly attributed to its high-quality production standards, there are other factors at play. Not the least of these is NS Tools’ forward-thinking approach to the market. “Our strategy,” NS Tools President, Hiroji Goto, confirms, “is to look ahead and prepare for future market needs, so that when these arrive, we are ready to meet them.”

The Worldfolio provides business, industrial and financial news about global economies, with a focus on understanding them from within.

“Some people claim to be able to trace a company’s future over the next five or ten years, but they are almost always wide of the mark," he says. "Company growth is not our main purpose; our strategy is not to set goals three years down the line. Instead, we need to watch the market closely and adapt to it accordingly. I do not want to dream the impossible. I simply want to make our company stronger.”

With the market for small end mills currently experiencing exponential growth, it is clear that NS Tool tagline ‘For Crafting Tomorrow’ is more than just an empty slogan.

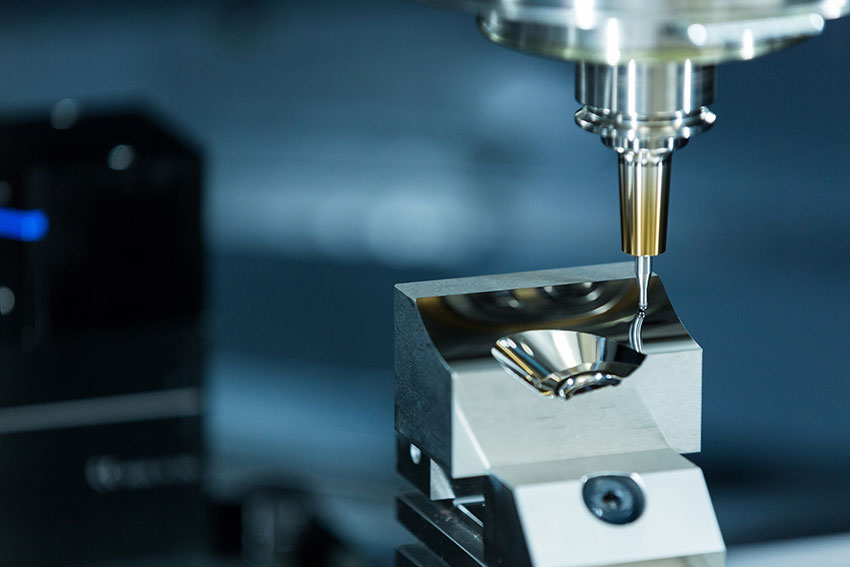

The benefits of such an approach can be clearly seen in the context of the miniaturization trend currently taking place in the electronics-based manufacturing industry. A decade ago, NS Tool developed the smallest diameter end mill in the world as a standard product, measuring 0.01mm in diameter. “This is even thinner than a strand of hair, which is on average around 0.1 mm. The technology paved the way for the creation of the Micro Edge end mill,” Mr. Goto emphasizes.

NS Tool's cemented carbide small-diameter end mills are a mainstay in the industrial world where only cutting-edge micro-precision machining will suffice.

A company that sets great importance on the Japanese concept of monozukuri (manufacturing craftsmanship), NS Tool was established in 1954 and will shortly celebrate its 70th anniversary.

Indeed, the firm is always on the lookout for innovations that have not yet reached the market, with the recent establishment of a new facility at the company’s Sendai factory offering the perfect environment for targeted research. As Mr. Goto explains: “The new R&D center at Sendai incorporates a seismic isolation system under the building which ensures that we can achieve mirror-like finishes in our machining processes.” By shielding the factory building from vibrations such as traffic, the company’s manufacturing process is guaranteed to be consistent – and the quality of the finished product high.

Mr. Goto’s desire for NS Tool to grow “naturally” with the market is in keeping with his aspirations for the company more generally.

In time, as Mr. Goto notes, “the electrification of cars and adoption of autonomous driving may turn vehicles into smartphones.” And while certain companies specializing in tools for engines are facing difficulties, thanks to the increased demand for electronic parts such as vehicle cameras, radars and sensors, NS Tool sees only “growth potential.”

18581906093

18581906093