Need help with Kennametal carbide grades - kennametal carbide insert grades

Solution:Increased efficiency. Reduced costs. Versatile, consistent performance. All with Seco CH1050 and CH2581 PCBN hard part turning insert grades. Designed for high-quality surface finishes, using fewer tools.

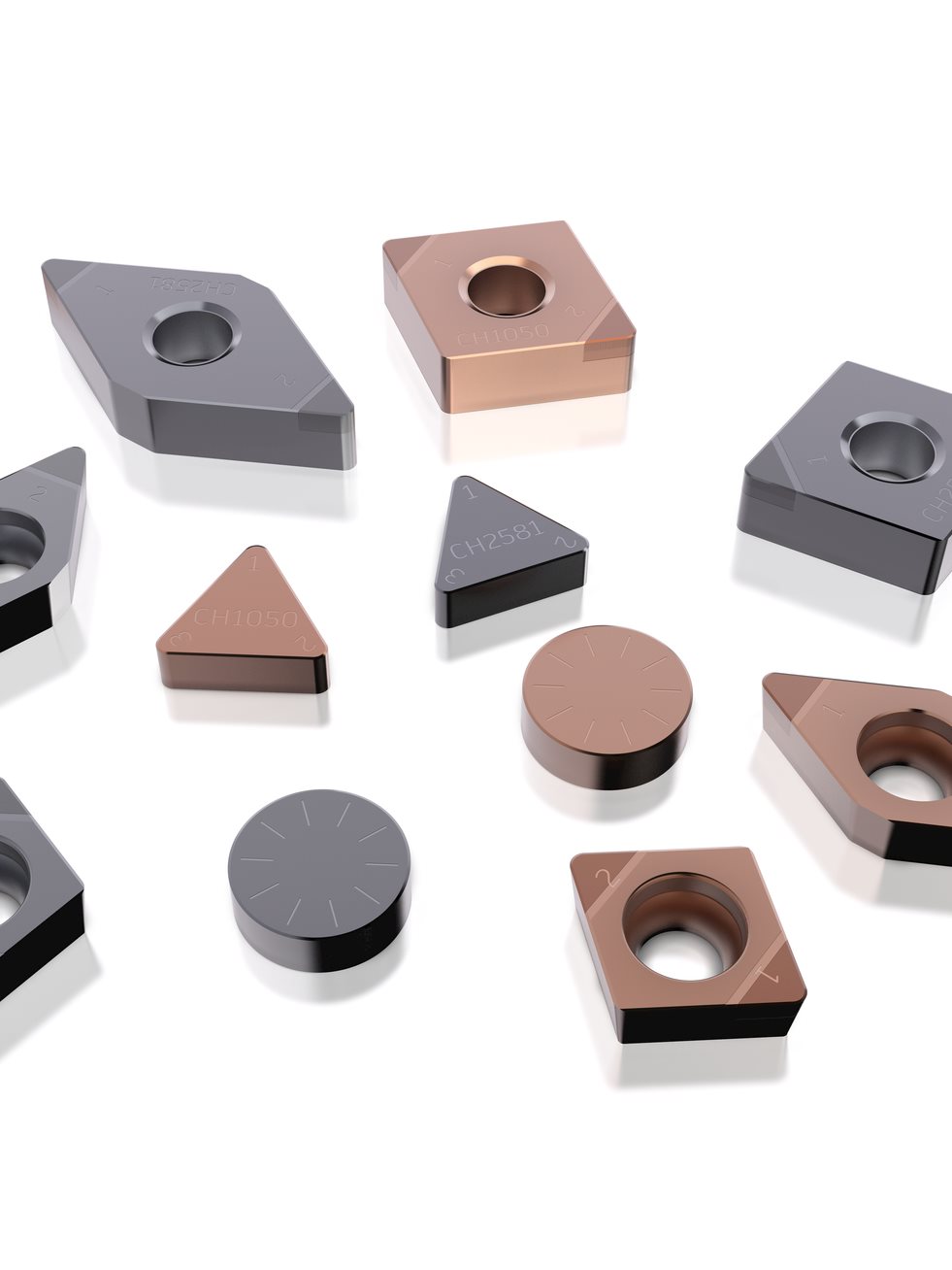

Discover the product range Hard Turning made easy To hard part turn steel components up to 62Rc, you need reliable tooling inserts. New Seco CH1050 and CH2581 PCBN insert grades make it easy to handle continuous and semi-interrupted operations that provide high quality surfaces. Think: high-accuracy edge preps and innovative coatings to deliver extreme performance consistency. Plus, longer tool life to lower your cost per part. Challenge: Inconsistent hard-turning tool performance slows production, increases job costs, and lowers part quality.Solution:Increased efficiency. Reduced costs. Versatile, consistent performance. All with Seco CH1050 and CH2581 PCBN hard part turning insert grades. Designed for high-quality surface finishes, using fewer tools. More Hard Turning. Less breakageHard-turning steel is tough on tools, especially with semi-interrupted surfaces. Avoid tool breakage and increase process stability with the new Seco CH2581 PCBN hard turning insert grade. Designed specifically for interrupted cuts, these inserts achieve 10% longer life with a high-accuracy edge prep. Plus, a unique Seco PVD coating. Challenge: Hard turning steel parts with semi-interrupted surfaces cause sudden tool breakage and scrapped parts.Solution:Seco CH2581 PCBN insert grade. Curb the risk of sudden tool breakages when hard part turning with semi-interrupted surfaces. Meet and maintain requirements with every finishHardened steel parts often come with exacting surface finish requirements. Many hard turning insert grades cannot consistently meet these requirements, even if the inserts don't show wear. Seco CH1050 PCBN grade hard turning inserts can. We use special high-accuracy edge preps and nanolaminate PVD coatings to give you 20% more tool life. Challenge: Hard turning inserts show minimal wear. But they still can't meet surface finish requirements for hardened steel parts through extended machining.Solution: Meet surface finish requirements for hardened steel parts with Seco CH1050 PCBN hard turning insert grade. Plus, discover the cost-saving benefits of extended tool life. Discover the product range Contact Us

Seco CH1050 PCBN grade hard turning inserts can. We use special high-accuracy edge preps and nanolaminate PVD coatings to give you 20% more tool life.

Solution:Seco CH2581 PCBN insert grade. Curb the risk of sudden tool breakages when hard part turning with semi-interrupted surfaces.

For steel , mild steel , hrc up to 45-55 with and without coolantR6 for EMRW6R-CUTTER BODY SUITABLE TO ALL MILLING CUTTER FOR R6 1204

Carbide insert for Steel and Stainless Steel machining with or without coolant , used in any suitable cutter for EMRW6R and this is used in milling machine mainly. Suitable cutter any cutter which suits RPMT1204 insert.

Hard-turning steel is tough on tools, especially with semi-interrupted surfaces. Avoid tool breakage and increase process stability with the new Seco CH2581 PCBN hard turning insert grade. Designed specifically for interrupted cuts, these inserts achieve 10% longer life with a high-accuracy edge prep. Plus, a unique Seco PVD coating.

Solution: Meet surface finish requirements for hardened steel parts with Seco CH1050 PCBN hard turning insert grade. Plus, discover the cost-saving benefits of extended tool life.

Challenge: Hard turning inserts show minimal wear. But they still can't meet surface finish requirements for hardened steel parts through extended machining.

To hard part turn steel components up to 62Rc, you need reliable tooling inserts. New Seco CH1050 and CH2581 PCBN insert grades make it easy to handle continuous and semi-interrupted operations that provide high quality surfaces. Think: high-accuracy edge preps and innovative coatings to deliver extreme performance consistency. Plus, longer tool life to lower your cost per part.

18581906093

18581906093