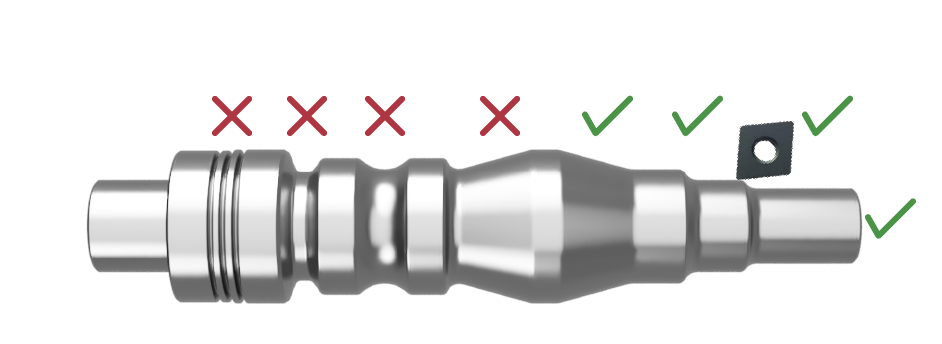

TopGroove™ NF3156LK Grooving Insert 3607333 - grooving insert name

The new screw-in type thread milling cutters are an addition to the existing ChipSurfer series 17Y_/18Y_ in partial profil range 55°/60°.

The TDXY insert is designed for various applications: external, internal and face grooving as well as turning applications. High feed capability due to the reinforced edge strength and optimal chip breaker result in improved productivity. The insert line enables good performance even in both continuous and interrupted cutting conditions; the straight front cut-ting edge shape not only enables a flat bottom surface when grooving but also improves tool life by minimizing chipping and notch wear.

V Type inserts, have a distinct shape with a 35° cutting edge.Here are the advantages and disadvantages of using V-shaped inserts in turning:

Ingersoll has expanded the RhinoTurnX line by adding the 70-degree corner angle XNMV1105 insert for multidirec-tional and high feed turning applications. The RhinoTurnX line dramatically improves productivity due to its all-directional and high feed turning capabilities.

![]()

The special Ingersoll HPC geometry offers multifunctional applicability of the ball end mills and meets the requirements for machining common material groups. The excellent roughing-finishing geometry can easily be used in different machining strategies.

It’s important to note that the advantages and disadvantages of D type inserts can vary depending on the specific cutting conditions, workpiece material, and the intended application. Manufacturers and machinists should consider these factors alongside their specific requirements to make informed decisions about insert selection.

This cutter series has ChipSurfer connections in maximum diameter range for reliable and highly effective machining, even in deep threads.

W type inserts (with 80° edge angle) are commonly used in turning operations, particularly for roughing and semi-finishing applications. Due to their versatility and effectiveness these inserts have specific advantages and disadvantages that are important to consider.Advantages of W type Inserts in Turning:

Our proven InnoFit modular adaption system is expanded by a I·Absorber vibration damped prolongation for shell type milling cutter in the length of 200 mm. This new I·Absorber prolongation can be combined with all standardized spindle adaptors and solid prolongations.

As part of the new innovative SFeed products, Ingersoll is introducing the modular DeepTwist tool for deep hole drilling operations. The modular DeepTwist "TD" part-hole drills in a stable design offer optimum performance, even with workpiece materials with a tensile strength over 1000 N/mm². The solid material design makes it possible to transmit high torsional forces.

A sharp cutting edge due to the ground fl ank face and high rake angle reduces cutting force, therefore provides good surface fi nish and longer tool life.

It’s important to note that the advantages and disadvantages listed here are general observations and may vary based on specific machining conditions, workpiece materials, and machine tool capabilities. Manufacturers and machinists should consider these factors along with their specific requirements when choosing the appropriate inserts for turning operations.

C Type (80° diamond) inserts are commonly used in turning operations due to their versatility and effectiveness. Here are some advantages in turning:

The TDT… -RS precision round type insert provides excellent surface fi nish for external and internal profi ling, turning and grooving applications.

In order to optimize our website for you and to be able to continuously improve it, we use cookies. With your acceptance you agree to the use of cookies. Further information on cookies can be found in our data protection declaration.

It’s important to note that the advantages and disadvantages of V-shaped inserts can vary depending on the specific application, cutting conditions, and the material being machined. Proper tool selection and setup, along with considerations for cutting parameters, are essential for achieving the best results.

Overall, W type inserts offer versatility, good cutting edge strength and cost-effectiveness, making them a very popular choice for roughing and semi-finishing turning operations. However, their limitations in finishing cuts, higher cutting forces, limited precision and size constraints should be considered when selecting the appropriate insert for a specific turning application.

The vibration damped prolongations are available for centering-Ø27, -Ø32 und -Ø40 mm at first in the modular Z5-size, i.e. outer Ø of 78mm, the smaller Z4-size with outer Ø of 61mm will follow soon in centering-Ø22 and Ø27.

18581906093

18581906093