91-10540 High Speed Steel Tap 5-40 - Plug - 5-40 high speed steel plug taps

Add products to your Micro100.com shopping cart and then submit the cart to a participating distributor to place your order

Micro 100 has built, and earned, an international reputation for manufacturing high quality solid carbide turning tools that are built to last.

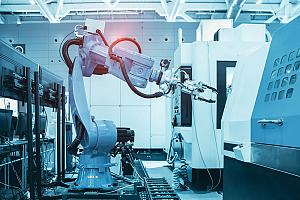

Micro 100 tooling is engineered using the latest CNC grinding technology and manufacturing practices to create the industry’s highest quality products.

These reduced neck end mills feature long flutes for deep pocket milling, and are stocked in either 2, 3, or 4 flutes, each o. . .

Micro 100 has built, and earned, an international reputation for manufacturing high quality solid carbide turning tools that are built to last.

Micro 100 tooling is engineered using the latest CNC grinding technology and manufacturing practices to create the industry’s highest quality products.

Add products to your Micro100.com shopping cart and then submit the cart to a participating distributor to place your order

EMUGE-FRANKEN USA has introduced its Cera-Cut end mills featuring a high-hardness cutting ceramic head brazed to a carbide shank for vibration dampening and long tool life. Featuring a high-feed duplex cutting edge geometry, the end mills produce high metal removal rates in challenging nickel-based alloys. According to the company, tool life is five times higher than regular carbide end mills.

Fully stocked in 2, 3, and 4 long flute styles, this ball profile end mill features a 30° helix and is offered with an AlTiN . . .

The end mills are designed for the consistent cutting of high-temperature resistant materials such as Inconel, Hastelloy, and Nimonic, as well as the machining of hardened tool steels. They are also suitable for making interrupted cuts, and offers a tight cutting diameter tolerance ranging from -0.0008 to -0.0016 in. (-20 to -40 microns), depending on the tool diameter.

Designed in our world class grinding facility in Meridian, Idaho, Micro 100's Micro-Quik product line is a breakthrough system that saves machinists countless hours without sacrificing performance.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

The end mills can be used for roughing or pre-finishing, and can produce 2D or 3D contours, and are suitable for face milling, slot milling, helical milling, contour milling, and pocket milling. They are offered in different diameters from 0.24 to 0.79 in. (6 to 20 mm). Corner radius, modular and special designs are also available.

Designed for general purpose machining, this solid carbide, ball profile, 30° end mill is offered with an AlTiN coated option. . .

Designed for general purpose machining, this solid carbide, 30° helix corner radius end mill is offered in 2, 3, and 4-flute styles in sizes ranging from .031" to 1 inch and is CNC ground in the USA.

The long length design of this square, reduced neck end mill makes it an excellent choice for deep cavity machining operation. . .

![]()

Designed for general purpose machining, this long reach, corner radius end mill features 2 flutes and reduced neck geometry, . . .

Micro 100 tooling is designed to excel at vastly increased speed and feed rates while providing exceptional results in a wide array of difficult-to-machine materials.

![]()

The design of Micro 100's PSC Holders combines a Capto® compatible connection with our proprietary Micro-Quik quick change system, which maximizes productivity by allowing for incredibly fast tool changes.

Designed in our world class grinding facility in Meridian, Idaho, Micro 100's Micro-Quik product line is a breakthrough system that saves machinists countless hours without sacrificing performance.

Micro 100 tooling is designed to excel at vastly increased speed and feed rates while providing exceptional results in a wide array of difficult-to-machine materials.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

The design of Micro 100's PSC Holders combines a Capto® compatible connection with our proprietary Micro-Quik quick change system, which maximizes productivity by allowing for incredibly fast tool changes.

18581906093

18581906093