Bending the rules - cnc tool insert material

YOU Milling Intelligently? QUICK-X-FLUTE – NEW Innovative Extended Flute Cutters Optimized for Efficient and Cost-Effective Roughing at High Material Removal Rates

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

“One could say that these advances, together with progressive capabilities in modern machines and CAM software, have paved the way for the new Y-axis turning method,” explained Staffan Lundström, product manager, Turning. “And with the tools and method now in place, we look forward to exploring the possibilities this method can present to our customers.”

The inserts can be used on GD-GH gundrills and BTA deep drilling tools for Ø14-28mm diameters. The line includes deep drilling inserts with 3 chip splitting cutting edges, positive rake chipbreaker, and a wiper.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

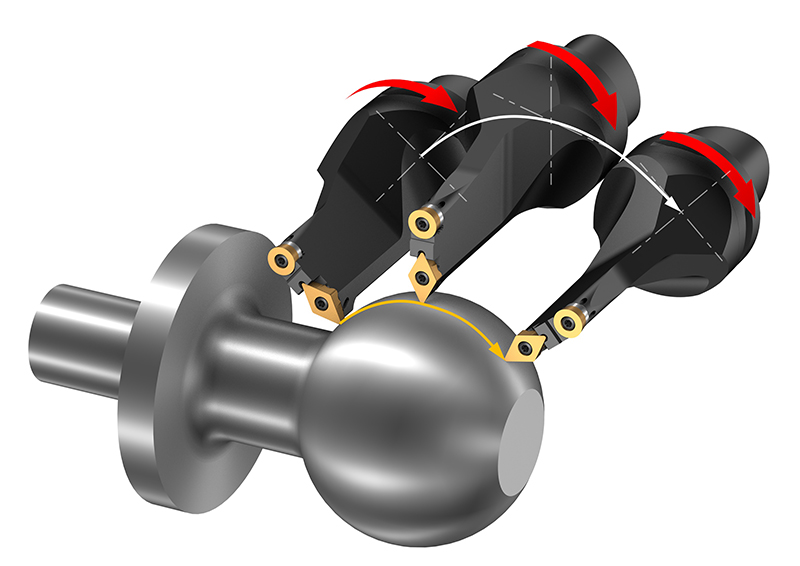

To summarize, Y-axis turning is a method for simultaneous three-axis turning with interpolation of the milling spindle axis. The new tools can also be used in “static mode” with a locked spindle for flexible two-axis turning with fast insert indexing. The method is suitable for all materials and requires a multitask machine with options to allow interpolation of the milling spindle axis during turning.

The ability to machine several features with a single tool reduces cycle time, and no tool changes are required, which minimizes the risk of “blend points,” or irregularities between adjacent machined surfaces. The main cutting forces are directed into the machine spindle, thus improving stability and reducing the risk of vibration. A constant entering angle drastically improves chip control and makes it easier to avoid chip jamming.

The technique makes use of the Y-axis, and all three axes are used simultaneously when machining. The tool rotates around its own center, the insert is placed for machining in the Y-Z plane and the milling spindle axis interpolates during turning. This allows intricate shapes to be machined with a single tool.

The GF chip former is characterized by a unique chip gullet that helps to cut the material to short chips at low to medium feeds. Chip former with positive rake results in an easy cut and avoids long and curly chips that may jam in the drill gullets and damage the tool. Available in a wide range of inserts in Grade IC908.

SANDVIK COROMANT has developed two new tools to support a new turning method – Y-axis turning. The new CoroTurn® Prime variant is recommended for turning shafts, flanges, and components with undercuts. The CoroPlex® YT twin-tool, featuring CoroTurn TR profiling inserts and CoroTurn 107 round inserts with rail interface, can be used for components with pockets and cavities.

18581906093

18581906093