Buy Carbide burrs MX cut 5 pcs Syska online - tungsten carbide burr bits

The new generation of SHOCKWAVE™ driver bits will include a variety of bit tip sizes, lengths and kit configurations of Phillips, Square, Torx®, Slotted, ECX™ & Hex driver bits. Designed to deliver maximum life, each bit is optimized with a unique Shockzone™ geometry in varying lengths and thicknesses to absorb torque in all applications.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

“Following the launch of SHOCKWAVE™ in 2009, several competitors have followed in our footsteps with their own imitation of the Shockzone™, but these designs do not absorb peak torque without snapping at the tip,” says James Grow, Sr. Product Manager for Milwaukee Tool. “As impact tools continue to gain momentum in the industry, and the available offerings have more power and more speed control than ever before, we are proud to be on the forefront of accessory solutions that deliver extreme durability for the most demanding tools and applications.”

MILWAUKEE, WI – Milwaukee Tool continues to deliver game-changing solutions with the next generation of their market-leading SHOCKWAVE™ Impact Duty driver bits. Engineered and tested to be the most durable, best fitting driver bits on the market, the new generation will feature an optimized Shockzone™ geometry to provide up to 30x longer life and absorb 3x more torque vs. other impact bits.

With the expansion of the SHOCKWAVE™ Impact Duty line, Milwaukee Tool demonstrates its continued commitment to delivering innovative accessory solutions to save time and increase productivity on the jobsite.

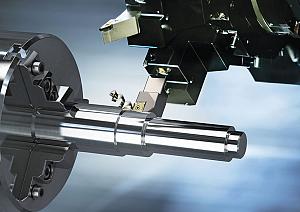

EMUGE-FRANKEN USA has introduced its Cera-Cut end mills featuring a high-hardness cutting ceramic head brazed to a carbide shank for vibration dampening and long tool life. Featuring a high-feed duplex cutting edge geometry, the end mills produce high metal removal rates in challenging nickel-based alloys. According to the company, tool life is five times higher than regular carbide end mills.

The end mills can be used for roughing or pre-finishing, and can produce 2D or 3D contours, and are suitable for face milling, slot milling, helical milling, contour milling, and pocket milling. They are offered in different diameters from 0.24 to 0.79 in. (6 to 20 mm). Corner radius, modular and special designs are also available.

In addition, the Precise Fit Custom Machined Tip™ prevents stripping and reduces wobble for the best fit in the industry. Made of Custom Alloy76™ Steel, a proprietary heat treat process maximizes resistance to wear and shock.

The end mills are designed for the consistent cutting of high-temperature resistant materials such as Inconel, Hastelloy, and Nimonic, as well as the machining of hardened tool steels. They are also suitable for making interrupted cuts, and offers a tight cutting diameter tolerance ranging from -0.0008 to -0.0016 in. (-20 to -40 microns), depending on the tool diameter.

18581906093

18581906093