Carbide Burrs in Standard & Double Cut - die grinder bits for steel

“I always recommend the highest quality holder you can get,” says MacNeil. “High feed and speed is used to maximize metal removal rates. Investing in a high quality machine and programming methods and not investing in quality tools and holders … is equivalent to owning a Ferrari and putting the cheapest tires you can find on it. You won’t win the race, and you may end up with damaged components.”

“Obviously the faster the rpm, the shorter the tool life … but tool life is really a small player in total cost,” agrees Mitchell. “I think you’re always better off running as fast as you can, within reason. If you have to go in and index your insert every three minutes on the machine [then speed is not a benefit]. You have to balance tool wear and speed,” he says.

“When it comes to high speed machining, we usually like to look at ALTiN [aluminum titanium nitride] coatings, primarily because of their heat resistance and their abrasion resistance,” says Jay Ball, product manager for solid carbide endmills, NAFTA at Seco Tools “In high speed machining, there’s a lot of heat generated.”

A previous Canadian Metalworking story noted that on the first indication of premature tool wear, chatter or chipping, machinists will often turn down the override controlling the feedrate. In such situations, however, might it be better to boost the feedrate instead?

“Higher than normal speeds and feeds can be applied to any material group by changing from conventional techniques,” suggests MacNeil. “Techniques allow for cutting data increases relative to material (for example, Titanium 6al4v at 250 sfm using standard toolpath can achieve 450-500 sfm with high feed side milling techniques),” he says.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

![]()

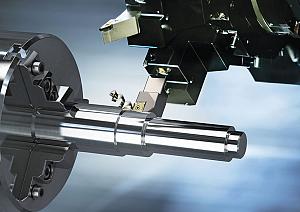

So, you want to maximize cutting speeds and feeds to reduce cycle times? If this is your goal, there’s a series of cutting tool factors to be considered, including coatings, coolant, materials, applications, etc.

One final piece of wisdom: Morrison advises machinists looking to maximize speeds and feeds to take a moment to reflect before commencing work.

“Tungaloy recently expanded its DoOcto line…this milling cutter can now take a double positive eight-edged insert or an eight-edged high feed insert. The high feed insert can be used as a conventional milling tool when the depth of cut exceeds the recommended depth for high feed,” says Mitchell.

“We have several new products out: Gold-Quad F and Gold-Quad XXX [high feed mills]. The first one, Gold-Quad F, is a 12-degree lead angle style tool. It does an excellent job of managing cutting forces and has up to seven different insert styles to address different milling scenarios,” says Fiorenza.

“When you’re running an interrupted cut in a turning situation, it’s almost always best to turn the coolant off and run dry [due to the risk of] thermal cracking,” states Mitchell.

The new-generation steel turning insert grades GC4425 and GC4415 deliver improved performance in every way. Coated with second-generation Inveio® technology, they have a broad range of applications and are recommended for continuous and interrupted cuts. See how our experts worked their magic and learn what drove them to create our recently launched ISO P steel turning grades – GC4415 and GC4425.

“Pretty much all of our tools are designed with coolant through applications in mind,” says Cullen Morrison, business development manager at Komet of America. “We also have applications for MQL [Minimum Quantity Lubrication]…we’re looking at how can we run these components as fast and as stable as possible,” he adds.

“Be conscious of average chip thickness,” echoes Fiorenza. “All high feed tooling has a feed rate multiplier associated with the tool that is different for almost every cutter. That multiplier allows you to compensate for chip thinning. You do have to be aware of slowing down the feed rate and possibly generating too thin of a chip in which case you end up rubbing the material … it’s a very important thing for end users of high feed milling tools to understand what their feed rate multiplier is,” he says.

“Until the process is secure and the programming suits the machine, material and fixturing, I don’t worry about wear. We can do a lot of damage before a tool wears,” says MacNeil. “To me it is the last factor left in the equation…wear is inevitable. Slow controlled wear that is predictable is the goal after we have everything else in the process secure.”

Tweaking the feedrate “depends on the situation…if you’re dealing with chip thinning, then yes you really need to ramp up your feed rate. If it’s not chip thinning, I’m not sure I would agree [with increasing the feedrate],” adds Mitchell.

“Another option for finishing or semi-finishing is to use cermet,” suggests Mitchell. “Cermet is capable of running at higher speeds than carbide, produces excellent surface finish and lasts a very long time. Use CBN in hard turning applications. Some shops are still grinding their hardened parts. It is much faster to produce these parts on your CNC lathe using a CBN insert,” notes Mitchell.

“We tell them, ‘look at everything as a system.’ Balance everything. You can’t put the cart in front of the horse. What are the limitations of the machine? What are its speed characteristics? You have to look at the whole system … it’s all about controlling the process,” states Morrison.

“Unfortunately, there’s really no tools that exist that allow you to take a very, very large depth of cut and also take a very, very aggressive feedrate. Because of the heat that’s generated, you either take a big depth of cut with a light feed or a small depth of cut with a high feed…you can only generate so much heat in a cut. The minute you generate more heat than what is needed, you’re going to burn out your cutting tool.”

“We have a new Plura endmill optimized for high feed side milling. This tool also incorporates new coating process technology designed to keep the coating intact at higher speeds,” says MacNeil.

“CVD grades have a thicker coating and are better able to withstand heat in larger arcs of engagement and high speeds,” explains MacNeil. “PVD inserts are thinner and sharper which is better at low arcs of engagement. They do not withstand heat as well, but we have less heat in the process when the arc is low,” says MacNeil.

“I would say that’s very relative to what the process is … a low feed rate does cause increased wear. If that is the reason for the wear, then a higher feedrate would be better. If the cutting speed is too high, a higher feed rate is not going to help. If you’re talking about turning hardened steel at 60 Rc, the wear on the tool is just going to be a fact of life,” says Morrison.

“A low arc of engagement tends to lend itself to high speeds and feeds…reducing the contact area of a square shoulder tool keeps the heat low and allows us to increase feed to compensate for chip thinning that occurs at the low arc of engagement. An example of this is often called Trochoidal milling in slots but applies to any shape,” states Brian MacNeil, milling products and application specialist, Sandvik Canada. “Also Dynamic milling is a common method supported by CAM software that uses small arc of engagement with higher speeds and high feeds,” adds MacNeil.

“Almost every application lends itself to cycle time reductions,” says John Mitchell, general manager of Tungaloy Canada. “The options available to reduce cycle time are almost endless. When turning, the maximum feed rate should not exceed half of the insert nose radius, therefore use the largest nose radius possible to increase feed rates. If the part requires a good surface finish or has some corner radii restrictions, use a wiper insert.”

We also wanted to know what materials work best in high speed/feed operations—and what materials are best machined slowly.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

“Typically when you deal with very, very high feed tooling, you’re also dealing with very, very light depths of cuts. So that’s the trade-off,” says Steve Geisel, senior product manager at Iscar Tools Inc.

Heat has the greatest impact on tool life, and speed has the greatest impact on heat. With this in mind, we asked pundits about the role of coolant in maximizing speeds and feeds.

“Because we’re talking about the heat generated, the quicker you can reduce the heat, the more aggressive you can be. Coolant is one means that you can reduce the heat in the cut. One thing we’ve developed, we call it our Jet HP line. It’s a high pressure coolant, tooling system. With our Jet HP line, people can run the coolant pumps up to 5,000 psi,” says Geisel.

Other tips from the experts: “Programming is the key in high feed milling,” says William Fiorenza, die and mold product manager at Ingersoll Cutting Tools. “Proper programming that utilizes high speed machining techniques and programing features such as corner welding and corner smoothing promotes free and smooth cutting and constant chip load. These are all key things you need to have to effectively high feed mill.”

“We have a new tool we’re releasing to the US market—the Brinkhaus ToolScope machine monitoring system. It monitors load on spindle, torque forces and other key indicators of machining performance,” says Morrison.

Other tips: if maximizing high speeds and feeds is the goal, use a rigid machine tool—“As rigid as possible. Rigid will benefit everyone,” says Morrison.

“High feed milling works well in a variety of materials including, but not limited to, carbon steels, alloy steels, stainless steels, heat resistant alloys, and titanium. Cutting conditions vary depending on the type of material,” says Paul Rice, applications engineer at Kyocera Precision Tools. “For example, slower feeds and speeds are used when machining heat resistant alloys and greatly increased when machining low carbon steels.”

“Kyocera recently released an innovative high feed milling line-up. The MFH-Raptor and the MFH Mini high feed end mills and face mills utilize new insert grades with complex geometries that drastically reduce spindle loads and are capable of extremely high feed rates for maximum material removal,” says Rice.

18581906093

18581906093