Corner Radius End Mills [Bull Nose]: Guide - bull nose cutter

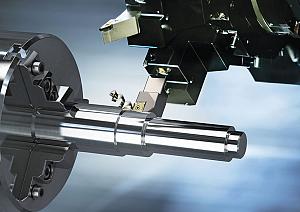

The anti-chatter boring bars have a serrated, bolt-on connection at the front of the bar that securely clamps a variety of styles and sizes of indexable heads.

Setting the head exactly on centreline is accomplished by bringing the angle finder to zero and then locking the bar in place.

Setting the head exactly on centreline is accomplished by bringing the angle finder display to zero and locking the bar in place.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

The vibration-free system has been shown to offer better boring performance in applications up to 10xD, explained Eichelberger, which is much deeper than solid-carbide or heavy metal boring bars are capable.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

Considering the higher cost of such a boring system, it’s important that heads can be replaced in the event of a crash, avoiding damage to the bar itself. And users of the company’s older boring system will find that their new heads fit with the use of an adapter.

Sam Eichelberger, Kennametal product engineer for lathe systems engineering, is part of the team that developed the tool’s internal dampening mechanism.

Kennametal’s new vibration-free boring system features interchangeable heads that include screw-on and lever-style clamping mechanisms in positive- and negative-rake configurations.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

“The portfolio for our imperial bars ranges from 1 inches in diameter up to four in., while the metric version starts at 25 mm and goes to 100 mm,” Gable said. “There are a variety of interchangeable head styles available as well, everything from screw-on, positive-rake inserts for fine-finishing needs to negative-rake, clamp-style geometries for heavy roughing.”

This vibration-free boring system also is essentially plug-and-play with an array of interchangeable heads, including screw-on and lever-style clamping mechanisms in positive- and negative-rake configurations.

It’s a sound that every machinist dreads: the high-pitch whine of a deep-boring operation complete with chatter loud enough to seep through even the best earplugs.

The manufacturer has addressed this critical consideration by supplying machine-specific turret adapters, along with a special split sleeve bushing for maximum rigidity.

There’s more to the story than making the shop a quieter place to work, however. Eliminating vibration and therefore chatter extends tool life and improves surface finish. And when tools last longer, they can be pushed harder, increasing feed rates, cutting speeds, and depths of cut.

“Perhaps the most important thing to know about the new bar is that it’s plug-and-play,” said Eichelberger. “There's no need whatsoever for tuning or adjustments; you simply pull it out of the package, mount it in the turret, and get boring.”

It’s a problem that plagues many machine shops that produce long, deep holes, and it only gets worse in materials that are tough and more difficult to machine.

“That’s the goal of this product,” said Kennametal Global Product Manager John Gable. “The greatest stability possible and the most effective dampening solution available, period.”

The heads themselves for this tool also have changed and now are shorter and lighter. This helps provide greater stability, contributing to the bar’s improved performance, the company states. They’re also coolant-fed, precisely directing a stream of high-pressure coolant where it’s needed most. The result is improved chip control together with maximum cooling in the cutting zone.

“There’s a reference flat on the top of the head that accommodates a visual angle finder,” Eichelberger said. “You just rotate the bar until the indicator reads zero, then clamp it in place.”

To battle the vibration of deep boring, which can cause drifting, out-of-round holes, and poor surface quality, tooling supplier Kennametal has introduced a new boring system with a new anti-chatter mechanism and numerous indexable heads and shank sizes.

With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. Register for the world’s largest manufacturing technology forum for free today to stay in the know. Learn more about us.

“The bars are both vibration- and maintenance-free. Within the bar there sits a mass that's supported by a pair of elastic supports, inside of which sits a dampening fluid. This mass vibrates at a predetermined frequency during machining, attenuating the natural frequency of the bar around it to suppress vibration. There are no wear components to worry about [and] no tuning,” said Eichelberger.

Anyone who’s ever struggled to get a boring bar exactly on centre will appreciate the fact that setup has been simplified.

The MD133 milling cutter offers high process reliability and maximum productivity with an optimal metal removal rate with reduced machining times.

18581906093

18581906093