Cutting tool wear | Find suppliers, processes & material - milling insert wear

HRH – Roughing Heavy For medium-duty to roughing. Outstanding chip control. High edge strength for interrupted cuts, forging skin, or scale. Preferred for all cast iron, such as gray, malleable, and nodular.

This insert has 3 cutting edges per side. The 80° cutting angle provides high cutting-edge strength for roughing, but the depth of cut is limited by the short cutting edge.

Whatever the thread pitch, profile or material, we can provide you with the solutions you need. The threading tools and inserts we offer help you produce quality threads for interiors and exteriors.

In just the same way that replacing threaded inserts is a straightforward process, removing them is equally straightforward. If you wish to see how to do this, please see below.

HFS – Finishing High-Temp For finishing applications. Ground periphery with positive cutting edge. Ideally suited for high-temp alloys. Micro-finished edge on the ground periphery adds just a slight hone for improved edge integrity and reliability.

HUR – Universal Roughing Roughing geometry, with smooth chip forming and improved coolant flow for increased tool life. Positive geometry reduces cutting forces, and improves depth-of-cut notching resistance. Ideally suited for stainless steel applications, and for smooth machining of steel.

The inserts have an external thread that resembles a coarse wood screw thread and an inside thread that resembles a fine machine screw thread. You can effectively use machine screws in wood with them, as they are useful for any item that will require the screw to be removed later. The threads of conventional wood screws are damaged when you remove them from the wood. If the line completely disappears from a wood screw hole, the screw will no longer be able to be fitted into that hole. Threaded inserts allow threaded machine screws, which is a more convenient method to accomplish this task.

These are suitable for sticky, work-hardening materials such as low-carbon steel, stainless steel, non-ferrous materials, and superalloys, to name a few. Their cutting edge is sharp, resulting in a high level of surface finish and low cutting forces.

For a stronger thread, it ensures the bottom, top, and depth of the thread are all in the right places. Also, regardless of the thread profile, this will help eliminate any deburring. Due to the larger nose radius, fewer passes are needed compared to a V-profile insert. In addition, it allows you to thread more efficiently. For this reason, it is necessary to have a separate insert for each pitch and profile.

This video uses insert nuts with an outside diameter of around 8.5mm, smaller than those I am using in the video. The first hole should be 9mm in diameter for something like this. You can use softwoods as thin as 8mm if you need a tight-fitting. The manufacturer should always determine the pilot hole size. For drilling depths, drills are equipped with depth-stops. This is especially useful if you need to drill many holes at once.

Choose the insert grade (coatings) based on the type of material being cut, the specific machining operation (finishing, medium, roughing), and the cutting conditions (smooth, lightly interrupted, heavily interrupted). The insert grade and the chip breaker complement each other to provide specific performance characteristics. A tougher grade can compensate for a cutting edge with less strength, while a more wear resistant grade can provide longer tool life on a stronger cutting edge.

There are several threaded inserts, each featuring a unique design, but they are all designed with female threading to support fasteners with male threading. A spiral design is a characteristic of circular threaded inserts, for example, and they are usually made of steel or bronze. The metal is coiled up in the appropriate size and shape to support the threaded fastener.

Choose the insert style (shape and size) based on the features of the part and the desired depth of cut. A larger nose radius is stronger, but requires more machine power, and increases the tendency for vibration. A smaller nose radius increases the access to fine part features, but has a weaker cutting edge.

There is no V-profile insert attached to the thread crests. Using the same diameter screw and nut is imperative before threading any screw or nut. This can be accomplished by turning the outer diameter of the screw to the same diameter as the inner diameter of the nut. Furthermore, it is possible to use the same insert for multiple pitches as long as the thread profile angle (60° or 55°) and radius are the same. As a result, the nose radius of the insert is smaller to cover the range of pitches, therefore reducing the tool life and creating Burrs on the tool.

The term internal thread refers to a thread found on nuts or tapped holes, while the term external thread refers to one found on bolts, studs, or screws. The axial thread form is the name given to orientated threads that are oriented axially. There are three parts to a thread profile. These are the crest, the root, and the flanks.

For thread turning, one of the most important considerations in choosing the correct insert geometry. Geometry affects many aspects of the tool life, such as chip control, insert wear, thread quality, and tool life in general.

HFF – Fine Finishing For finish turning, producing smooth, accurate surfaces. Very good chip control, especially at low depths of cut

The GlobalSpec SpecSearch database provides information about many different types of threading inserts. Most are described according to shape.

HMP – Medium Positive (Single-Sided) For medium to rough turning, with reduced cutting forces and improved chip control for high feedrates. Suitable for high metal removal rates.

HFP – Finishing Positive (Single-Sided) For finishing to medium turning operations, with optimal chip control over a wide range of cutting conditions and workpiece materials.

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

HUF – Ultra-Fine Finishing For finishing, with a positive cutting edge for reduced cutting forces and superior surface quality.

CCET – Finishing Positive (Single-Sided) For finishing turning operations, with optimal chip control over a wide range of cutting conditions and workpiece materials.

Additionally, some inserts feature a nut wrapped around female threading that belongs to this kind of product; when a fastener is driven into the cage nuts, the tops of the nuts feature “wings” that dig into the object when the fasteners are driven into them.

Hardwoods, softwoods, and plywood all work well with press-in inserts because of their barbed exteriors. The well should be drilled so that the body of the insert will fit inside the hole. You can clamp the insert into place or tap it with a hammer and a block of wood. The drilling hole needs to be deep enough so that the epoxy engages only the tips of the insert barbs. This is especially important for applications where the clamping action tends to pull the inserts out of the wood, such as knobs on a drill-press fence extension.

For external machining and facing. The large point angle is very rigid, and good for rough machining. This is the most commonly used insert.

Among threading inserts, some have a single cutting surface, while others have multiple surfaces which can be used to continue threading when a tooth wears out. Several dimensions determine the number of sides and angles of the threading insert.

Once you know all the necessary details regarding threading inserts, you will now be able to use threading inserts in CNC threading more efficiently. It is important to remember all the steps mentioned above to give the best shot of Inserting the threads.

HMU – Medium Universal A medium universal geometry with a soft cutting action due to its positive geometry. Has a versatile application range, and is suited for turning unstable components and for boring applications.

HMR – Light to Medium Roughing For light to medium roughing of steels, difficult-to-machine high-alloy titanium, and aluminum materials. High strength to deal with heavy chip deformation.

Inserts with threads are an excellent choice for reinforcing threads on bolts and studs when they are frequently installed and removed. Choosing the right threaded inserts when working with weaker materials can provide a strong, durable solution.

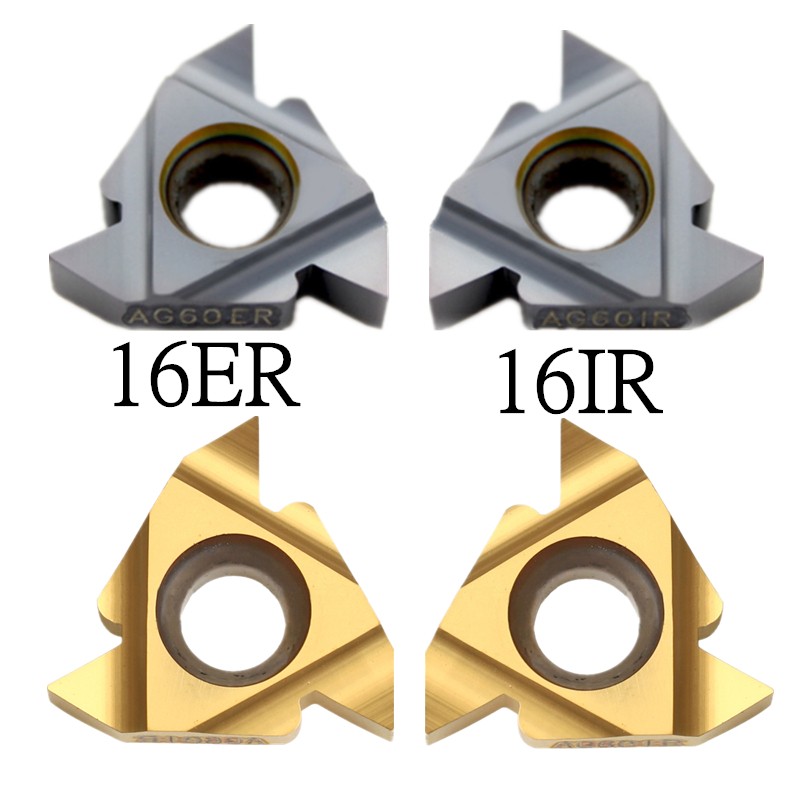

Some of the most common or standard angles for turning inserts include 55, 60, and 90. There could be some variation in these, but they are most frequently used. In addition, some common models of threading inserts include 16ER AG55, 16IR AG55, GC1125, GC1135, GC1025, 16er ag60 insert, 11er a60, 11ir a60 inserts, 16Ir ag60 insert and CB7015.

In terms of threading, externally threaded inserts are those with threads on the exterior, as their name implies. The threads have been internalized, but the external threads are also present. In this regard, I would like to know what this external threading is for. It is much easier to drive them into predrilled holes if they feature external threading since they can easily be driven into them.

It can be challenging to fit the screw into the hole. Some screws include a hex socket built into the head. You can use flat blade screwdrivers with the slot. You can prevent the machine screw from moving by using the one you plan to use in the final fitting and attaching a locking nut. Once the insert nut is fully driven home, it can be finished with an impact driver. You can remove the machine screw by removing the nut with a small spanner. In addition to threaded inserts with heads.

HMS – Medium High-Temp For medium machining in high-temp materials. Utilizes a micro-finished edge preparation to increase edge toughness.

Inserts with threads on both the outside and the inside of the carbide threading insert are called externally threaded inserts. Generally, the inserts are threaded into a pre-tapped hole, or, in the case of some carbide threading inserts, the inserts can tap their own thread into a drilled or molded hole. Various types of anchorages are then used, including nylon locking elements, as well as other means.

The smaller point angle of this insert is more versatile for finishing and detail work, but it has less cutting-edge strength than other geometries.

HUM – Universal Medium For medium-duty turning operations. Soft-cutting chip breaker. Used in applications producing varying chip sections, such as profile or copy turning. Good dimensional accuracy. For soft steel materials and stainless steels.

There are many variables that go into choosing the correct insert for your turning operations: insert shape, geometry, grade, and more. The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness.

Full profile inserts are the most popular inserts. With this tool, the crest of the thread can be cut completely, as well as the thread’s profile.

Unlike full profile inserts, multi-point inserts have more than one insert point (NT>1), similar to full profile inserts. If an insert consists of two points, the productivity is doubled. If an insert consists of three points, the productivity is tripled. As a result, the tool’s life is extended, productivity is increased, and costs are reduced since fewer passes are required. Because the cutting edge has a longer contact length, stable conditions are necessary due to the increased cutting forces. Besides being able to clear all the teeth, it also needs to have a sufficient gap behind the last thread for the insert to insert fully.

When threading is necessary for your application, precise and consistent threading is paramount. Huana Tools offers an exclusive selection of high-performance threading inserts that will ensure 100% accurate threading every time. Huana Tools threading inserts are made of tungsten carbide for both standard and custom threading applications. Our threading experts are also ready to help you improve the threading of your products.

Flat geometry provides overall functionality; it can be used to work with a wide range of materials. A round cutting edge adds strength to the cutting edge.

Choose the chip breaker (geometry) based on the selected machining operation: finishing, medium, or roughing. Roughing with high depths of cut and feedrates requires an insert with a stronger cutting edge.

The smaller point angle of this insert is more versatile for finishing and detail work, but it has less cutting-edge strength than other geometries.

For internal machining. The 60° cutting angle provides medium cutting-edge strength that allows for both ID roughing and finishing applications.

In softer woods and plywood, thread-in inserts are a good choice because their coarse outside threads ease the cutting process. You can then screw the insert into place by drilling a hole the right size for its body. White oak and maple are hardwoods, so drilling a hole slightly larger than the outside thread diameter and epoxying in the insert is recommended. If the insert is close to the edge of the part and screwing it in might split it, make sure to drill a hole slightly larger than the outside thread diameter. It would be best if you covered the end of the insert with epoxy to protect the threads inside.

Finishing operations with light depths of cut and lower feedrates produce lower cutting forces, so cutting-edge strength is not as important. Medium turning operations, with a wide range of depths of cut and feedrate, require a more versatile geometry.

This type of geometry is used for materials that are long in the chips. The product can also be used as a byproduct to strengthen stainless steel, alloyed steel, and non-ferrous metals. A machining geometry optimized for chip-forming to maximize the efficiency and precision of the process. The use of this geometry is not recommended for radial infeed operations.

18581906093

18581906093