Cutting tools of Cemented Carbide - carbide insert manufacturing process

Sorry, we just need to make sure you're not a robot. For best results, please make sure your browser is accepting cookies.

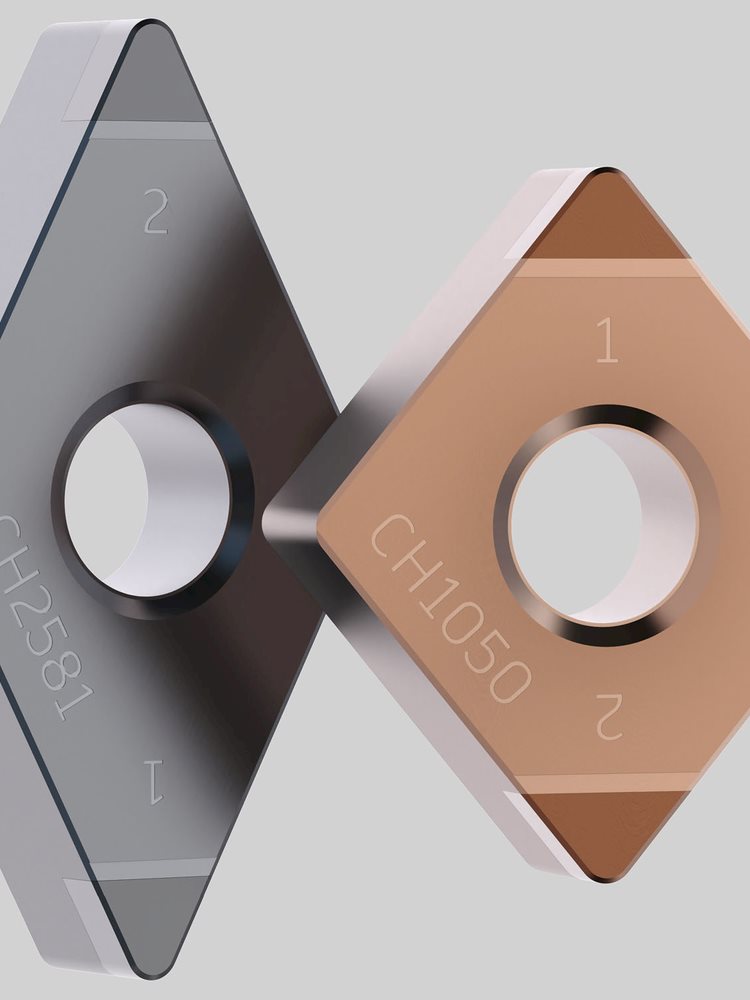

Selecting the right grade for the specific application is crucial for the success of a PCBN-test. The selection should be based on the application, but it is also important to look at the existing grade, cutting data and tool wear to be able to make the right choice.

The competition was using a tougher grade suitable for more interrupted turning. Tool wear was chipping of the insert. Looking at the surface of the component, it was obvious that there were small vibrations present.In this case it was not possible to reduce the vibrations (by changing machine tool, clamping etc), so CBN060K was selected, which is tougher than CH0550, and more able to resist the vibrations, and the result was 25% longer tool life than the competitor.

In a continuous application, turning the face and inner diameter of a gear, a typical H05 application, a hard and wear resistant grade like CH0550 should be the right choice, but testing was not successful.

Selecting the right grade for the specific application is crucial for the success of a PCBN-test. The selection should be based on the application, but it is also important to look at the existing grade, cutting data and tool wear to be able to make the right choice.In a continuous application, turning the face and inner diameter of a gear, a typical H05 application, a hard and wear resistant grade like CH0550 should be the right choice, but testing was not successful. The competition was using a tougher grade suitable for more interrupted turning. Tool wear was chipping of the insert. Looking at the surface of the component, it was obvious that there were small vibrations present.In this case it was not possible to reduce the vibrations (by changing machine tool, clamping etc), so CBN060K was selected, which is tougher than CH0550, and more able to resist the vibrations, and the result was 25% longer tool life than the competitor.Two conclusions can be drawn from this:When selecting the grade, look at the application, and look at what the competitor is using. In this case, the competitor had selected the right grade. CBN060K has been available for a while, but it is part of the HPT-chain, and still a very good grade, and it has its given position in the wear resistance versus toughness (ISO application area) chart, fully capable of beating any competitor in the H15 area. In a continuous application, turning the face and inner diameter of a gear, a typical H05 application, a hard and wear resistant grade like CH0550 should be the right choice, but testing was not successful.

18581906093

18581906093