Big Kaiser adds 30 pressed-geometry carbide inserts for its tools - carbide insert geometry

CBN grades are available for continuous cuts, light interruptions, light and heavy interrupted cuts, and heavy interrupted cuts and unstable conditions, depending on what the project calls for. The binding force between particles and grain size determines whether the insert is suited for hard or tough applications.

Easily access valuable industry resources now with full access to the digital edition of Canadian Metalworking.

Tool wear depends on a number of factors, including workpiece material, CBN grade, cutting conditions, edge geometry, and machine stability. In HPT, the most common forms of CBN tool wear are crater and flank wear.

“The toolpath is key to an efficient cut and achieving the best insert tool life,” said Howard. “It’s important to create a program that eliminates cutting conditions that will prematurely wear or reduce tool life. Key aspects to focus on are the entry and exit angles of the insert, sudden directional changes, and interrupted-type toolpaths.”

One of the major advantages of HPT as a process is the elimination of coolant. This is because both CBN and ceramic inserts can tolerate high cutting temperatures. Image courtesy of Sandvik Coromant Canada

“Successful HPT demands not only suitable cutting tools, but also the right conditions, preparation, and environment,” said Guruswamy. “The soft state is the state in which the workpiece material is yet to be hardened to its final hardness (around 20 to 40 HRC).”

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

“CBN is, however, the ultimate cutting tool material for HPT,” said Burton. “Modern CBN inserts offer up to eight edges per insert and built-in security that further enhances the bondage of CBN cutting tips on negative inserts.”

He also noted that HPT shares a lot of basic principles with soft turning, so machinists can easily transfer their knowledge and skill from one to the other. Alternatively, grinding requires very specific skills and an experienced machinist to perform similar tasks.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

“A one-cut strategy is feasible for both external and internal operations,” explained Burton. “However, a stable setup is important, and tool overhang should not exceed the bar diameter in internal turning (1xD). The big advantage of a one-cut strategy is minimal cycle times, although the trade-off is reduced tool life and potential difficulties in meeting stringent dimensional tolerances.”

“Concentricity and perpendicularity of the part will be much better in parts that are finished using HPT with a single setup,” said Ashok Guruswamy, product manager, grip/turn/thread, Iscar Tools Inc. Canada, Oakville, Ont. “Machining a taper and radius profile surfaces and complex contours are possible in HPT. In grinding, this would require a custom dressed wheel.”

Beyond grades and geometry, edge preparation selection is important for protecting the cutting edge and achieving good tool life. However, Guruswamy added that sharp edges are generally not recommended on CBN since a sharp edge can chip or break. In situations where cutting forces need to be reduced because of an unstable setup like in internal boring applications, machine limitations, or workpiece clamping, a sharp edge can then be used.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

Guruswamy noted that machining on an older machine versus a new CNC machine really makes zero difference in the overall output. As long as there is a high degree of stability and no vibration, HPT will be effective.

Last but far from least among HPT considerations is a machining strategy, with the choice made very often a balance between accuracy and productivity.

“This is because both CBN and ceramic inserts can tolerate high cutting temperatures. Typically, the heat generated when performing HPT operations is distributed into the chip (80 per cent) and insert (10 per cent), with only the remaining 10 per cent entering the workpiece.”

“HPT provides flexible machine utilization as the same machine can be used for external and internal machining,” said Kevin Burton, turning product and industry specialist, Sandvik Coromant Canada, Mississauga, Ont. “Complex component shapes can also be machined in a single setup.”

Howard added that cubic boron nitride (CBN) inserts associated with HPT are much more cost-effective than purchasing a cylindrical and centreless CBN diamond grinding wheel. Although the grinding process can achieve higher tolerances, cylindricity, and roundness, there are a number of benefits with opting for HPT.

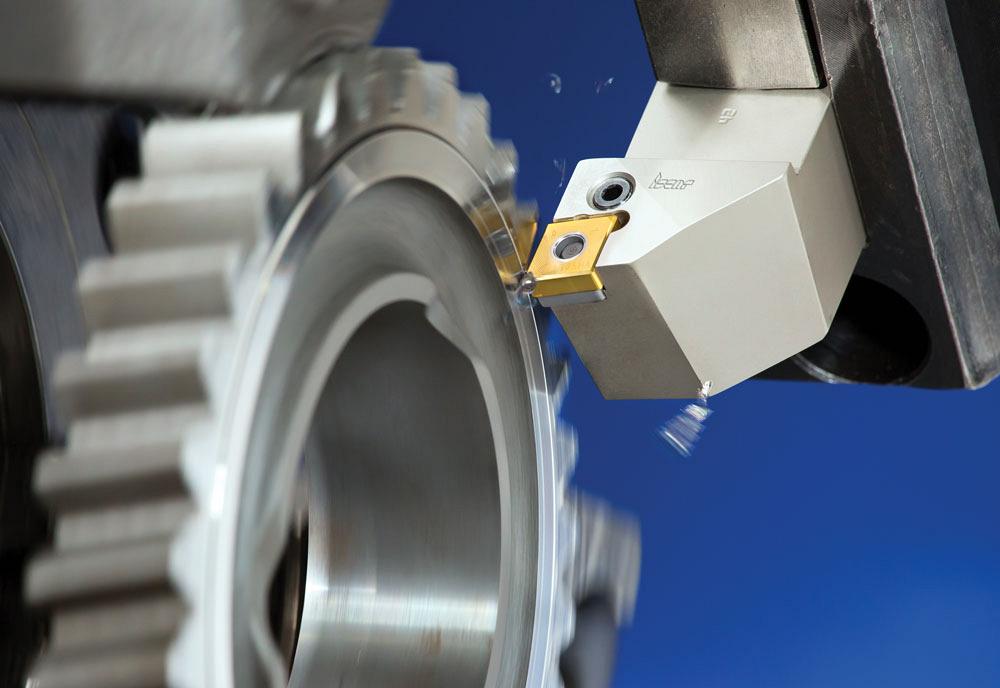

The high hardness of CBN enables it to machine hard materials at high speeds and feeds. However, successful HPT demands not only suitable cutting tools, but also the right conditions, preparation, and environment. Image courtesy of Iscar.

“The insert geometry, as with any operation, should be chosen based on the strongest geometry allowable for the specific application while considering the cutting efficiency,” said Howard.

Hard-part turning (HPT) has many advantages to help shops achieve better accuracy more efficiently in hardened steels from 45 to 70 HRC, superalloys, sintered materials, and grey cast iron. In recent years turning has eclipsed grinding as the preferred method for producing parts in their hardened state. As a process, it has been proven to reduce machining time and costs by 70 per cent or more over more traditional methods.

“Flank wear is the type of wear you would want to see on any insert,” Burton added. “It is the most predictable and progresses over time. Premature flank wear is not ideal, though. Large flank wear has a negative effect on surface integrity and dimensional accuracy. Even though wear is complex, there are ways to control it and maintain a consistent and reliable machining operation.”

Lindsay Luminoso, sr. editor/digital editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

When it comes to HPT, insert geometry should be chosen based on the strongest geometry allowable for the specific application while considering the cutting efficiency, said Howard. Image courtesy of NTK Cutting Tools

Not only that, but there are significant environmental concerns when it comes to grinding, particularly in relation to the slurry left behind. The mix of coolant and grinding dust needs to be disposed of properly, and in many cases separating the coolant from the mixture can be time-consuming. Many shops will look toward HPT as an alternative to grinding because it can be dry-machined, eliminating this challenge. However, HPT has its own set of demands and challenges that need to be overcome before it can be effective. Choosing the right cutting tool for the job is necessary.

Applying regular cutting insert grades to hardened steel will simply fail. HPT demands CBN or ceramic grades to ensure successful processing. CBN inserts are designed to withstand the high cutting temperatures and forces associated with HPT while retaining their cutting edge. Ceramic grades can be used on materials between 50 and 60 HRC when surface finish demands are moderate. Ceramic grades offer good heat resistance and high wear resistance and can prove beneficial for light, continuous HPT.

“When using standard flat top CBN without chipformers, long, unbroken chips are often produced,” said Guruswamy. “It can harm the workpiece surface finish and even interrupt the machining process. CBN inserts with chipformers will provide improved chip control at various depths of cut.”

HPT demands CBN or ceramic grades to ensure successful processing. CBN inserts are designed to withstand the high cutting temperatures and forces associated with HPT while retaining their cutting edge. Image courtesy of Iscar

The two-cut strategy is ideal in situations where too much material was left on in the soft stage. If an operator is trying to remove too much material with one pass, the cutting forces and pressure involved could be detrimental. In this scenario, a two-cut strategy could be a good option.

Modern CBN inserts offer up to eight edges per insert and built-in security that enhances the bondage of CBN cutting tips on negative inserts, said Burton. Image courtesy of Sandvik Coromant Canada.

Flank wear can be limited by increasing both the cutting speed and feed.DRY MACHINING“Of course, one of the major advantages of HPT as a process is the elimination of cool-ant,” said Burton.

An alternative is the two-cut strategy, which is ideal for unattended machining of high-quality surfaces. In this scenario, both inserts should have a wiper geometry. One of the main advantages of this strategy is it provides higher security, closer tolerances, and potentially longer runs between tool changes.

OSG’s A-BRAND® ADO-TRS drill is an advanced performance high-feed 3-flute carbide drill. Patented geometry provides stable chip ejection, even with less flute space inherent in 3-flute drills. The result is up to 3X faster cycle times and 3X longer tool life than 2-flute drills.

The experts agree that the use of features such as chamfers and radii on the part will help with entry and exit paths to maximize tool life, especially because sharp corners can damage or break the cutting edge. Also, operators should avoid burrs and use wiper inserts to achieve superior surface finish.

Careful preparation of the component in the soft (unhardened) state will significantly increase success in HPT. One way to achieve this is through machining as close as possible to the final dimension, leaving only a few 10ths of an inch for finishing. HPT requires a relatively small depth of cut, so tight dimensional tolerances in the soft machining stage will make all the difference.

“With crater wear, you’ll want to try and get the crater about a third or two-thirds the way up of the negative land that’s put on the inside of the insert,” said Burton. “When the crater gets too big, the edge will basically chip away and break, because it weakens the edge.”

“Clamping and alignment of the workpiece are also crucial,” said Burton. “As a guide, a workpiece length-to-diameter ratio of up to 2-to-1 is normally acceptable for workpieces that are supported on only one end. If there is additional tailstock support, this can be extended.”

Guruswamy added that another benefit of dry machining is that during the turning process, the material becomes slightly softer as it heats, making it easier to machine. He noted that dry machining is not always advised, even though it offers economic and environmental benefits. For example, in cases of continuous turning, when high surface finish is required, coolant should be applied.

For productivity, a one-cut pass would be the best option, especially because HPT should be more of a finishing process rather than a roughing process. After the correct cutting strategy is deter-mined, proper programming will help ensure long tool life. This will be enhanced if proper soft machining strategies have been put in place.

“Also, in many aerospace applications it is a requirement to use coolant to ensure surface integrity of the component,” Burton said.

Beyond the cutting strategy, machining conditions also come into play. Having good machining stability and rigidity will help eliminate vibration, which is absolutely critical in HPT.

“An important element of CBN is the wiper configuration, which helps greatly to improve surface finish and quality similar to grinding,” said Guruswamy. “Wiper inserts enable work with a higher feed and good surface finish on the workpiece.”

According to Howard, coatings also will help protect the insert edge from the heat generating during machining and will provide an excellent surface finish on the part. For example, a physical vapour deposition coating adds wear resistance, helps to improve cutting conditions, and extends the tool life.

And it plays a vital factor in successful turning of hard workpieces. When it comes to insert geometry, the experts agree that with respect to insert corner geometry, a wiper configuration allows for significant process improvements and productivity gains.

“A part design with specific features can be generated with the standard tooling and insert geometries,” said Steve Howard, engineering and marketing manager, NTK Cutting Tools, Wixom, Mich. “A grinding wheel applied to the same part would need to be specially made with features dressed into the face of the wheel, only adding to the already costly tool. In certain circumstances, where very fine finishes are required on the part surface, grinding will be necessary.”

18581906093

18581906093