Endmills - metric Vs imperial - nominal end mill sizes

With over 40 years experience in press tooling, our efficient, high quality service is best suited to companies looking for runs of between 500 to 10,000.

Total Carbide has an extensive stock of more than two thousand existing die sets which can be used to produce a wide range of unique Tungsten Carbide cutting inserts for the metalcutting industry.

Let’s start by choosing the best type of Face Milling Cutter for your Face Milling needs. The biggest differences between Face Milling Cutters are:

If you’re on a CNC Router, a very common operation is “Spoilboard Surfacing“, and while the router crowd likes to call the milling cutters used for Spoilboard Surfacing “Spoilboard Cutters”, they’re just another form of Face Mill.

Use of Wiper Inserts can greatly improve the surface finish when Face Milling. High feed rates and low depth of cut (0.8mm or less) will facilitate this. PVD (diamond) inserts with very sharp edges can also improve your surface finish.

Of course you can use end mills for surfacing, but it is seldom optimal to use an end mill. There are two major problems using end mills.

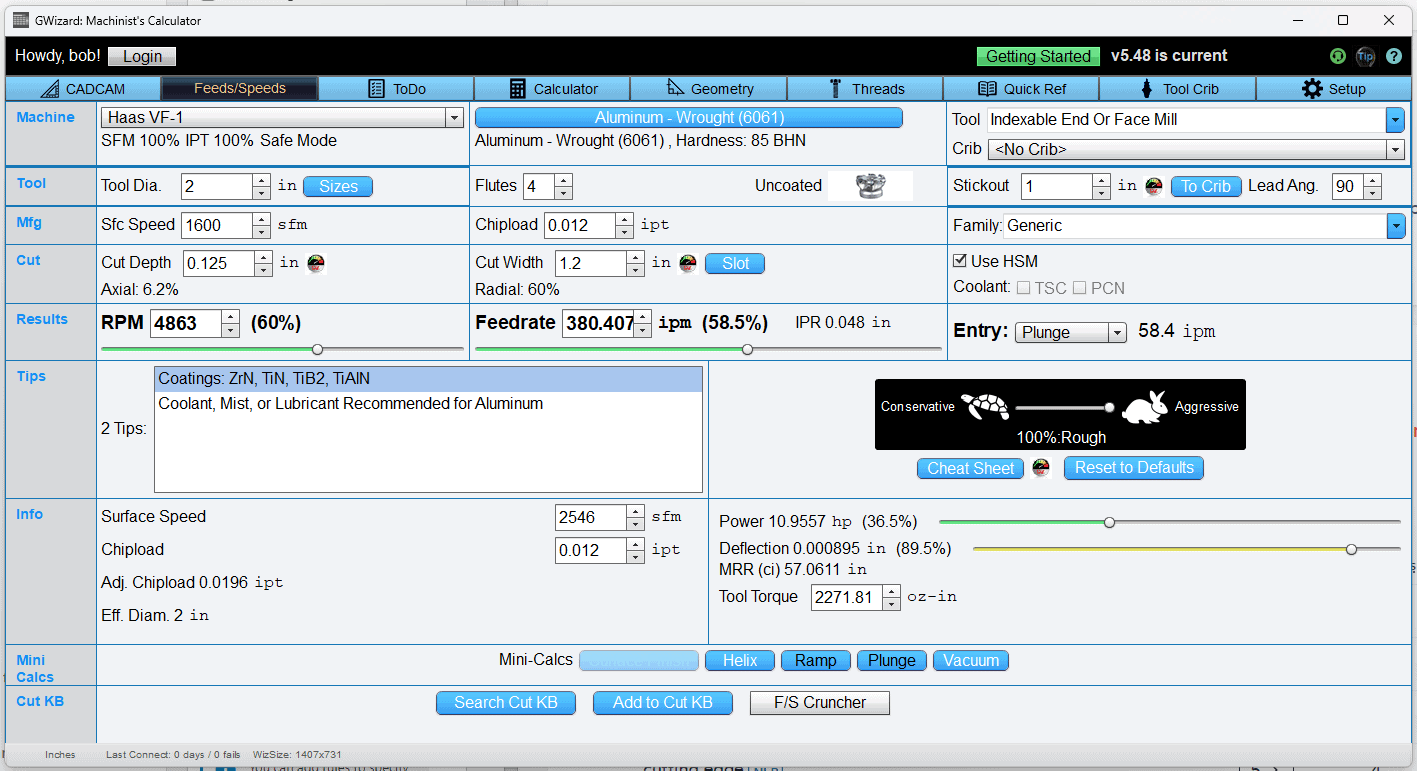

I did do a couple of jazzy things. First, I’m doing a 60 percent width pass. This will give a better finish and go easier on the inserts in tough materials than a full width pass. Second, I have specified this as an HSM cut. That’s HSM for “High Speed Machining.”

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

If you’re primarily after a great finish, then you probably want a fly cutter. The lowly fly cutter gives the best finish in most cases. BTW, you can easily convert any face milling tool to a fine fly cutter by simply removing all but one cutting edge.

One last thought about face mills–they’re horsepower hogs. Don’t try to use too large a face mill on your machine. I’ve stalled the 3 horsepower spindle of my mill running my 3″ pretty easily. Granted, it’s a smaller mill, but you need to keep in mind even if you have plenty of spindle power that the face mill is going to transfer a whole lot of it into your workpiece. Make sure it’s clamped down tight!

What is Face Milling? Think of milling with the side of an end mill. The general term for that is “peripheral milling”. Now, what if we cut strictly with the bottom?

Other alternatives include 75 Degree Face Mills and Button Cutters (Round Insert Indexable Mills). The 75 Degree Face Mill’s primary purpose seems to be providing just a bit more clearance than the 45 degree can. It might be your 3rd or 4th choice if you already have a 45 and 90 and want more options for difficult cases.

Louis, thanks for raising that issue. You’re quite correct about the 45’s higher axial forces and the issues they may cause for a workpiece that is not well supported or perhaps that is simply a bit thin.

And lest we forget button cutters, they combine some of the advantages of each plus they are also the strongest. So if you have to deal with nasty materials, a button cutter might be your best choice.

Yes! The angle is the angle of that cutting edge–45 degrees for the cutter on the left and 90 degrees for the one on the right. That angle is also called the lead angle of the cutter.

Working in conjunction with our customers we can offer expert advice on specific design criteria ensuring you end up with the best solution for your application. We are not restricted by size or shape.

I selected my machine, workpiece material, and indexable tool type. I’m modeling a smallish 2″ diameter face mill with 4 inserts, and I have set the Lead Angle to be 90 degrees. My Cut Depth is 1/8″.

If there’s a slot or other recessed feature in the surface you’re Face Milling, you’re going to be doing some interrupted cuts. This is hard on the inserts, so if you’re dealing with a tough material, you may want to reduce the feedrate up to 50%.

I can do that since I will use a toolpath that arcs gently into the cut and I will arc the end of each pass to avoid a sharp corner and also to avoid completely leaving the cut. Those are CAM toolpath tricks that can really help you out on tool life, surface finish, and in this case, they let you opt for a big increase in feeds and speeds too. If your CAM won’t do those things the Conversational CNC Face Milling Wizard in G-Wizard Editor will do them very easily.

At one time, octagonal face mills were at war with the 45 degree face mills for supremacy. The octagonal inserts have more edges, so you can rotate the insert if one gets chipped. But, tooling costs are usually only about 3 percent of the manufacturing cost, so the greater efficiency of the 45’s eventually won out.

I keep a 2″ diameter 90 degree facemill in my shop as well as a 3″ Glacern FM45 45 degree face mill. The FM45 sees a lot more use for sure.

Now, we can check out the 45 degree face mill / shell mill just by changing the lead angle to 45. Let’s assume every thing else stays the same, here are the results:

Technically, that’s face milling, though we typically only refer to it as face milling when we are using special milling cutters called “Face Mills” or “Shell Mills”. Note that there is literally no difference between face mills and shell mills.

Try to roll into the cut with an arc. It will improve your finish as well as your insert life. More toolpath ideas here.

As we do not market our own range of tooling and inserts we offer a completely confidential service. Our experience in tooling design enables us to provide innovative solutions for new applications, safeguarding revenue streams for replacement inserts.

Of course if you can afford it, it’s great to have both 45 and 90-degree face milling tools, but what are the pros and cons for each?

Lately, you can get some face mills that use a 45 degree insert that’s double sided, so we have the best of both worlds since these inserts now have 8 edges like the octagonal inserts.

Louis, thanks for raising that issue. You’re quite correct about the 45’s higher axial forces and the issues they may cause for a workpiece that is not well supported or perhaps that is simply a bit thin.

Be careful where you use 45 and 90 degree cutters. A workpiece that is not well supported, will deflect under a 45 degree cutter due to the high axial forces. A 90 degree cutter will produce a more consistent cut and the corresponding decrease in chatter will extend the life of the cutter.

First, what are we talking about when we say 45 or 90 degrees? The answer is fairly obvious from the photo above comparing two Glacern cutters. Take a look at the angle of the cutting edge on the inserts.

Contact Total Carbide and find out how we can help to provide you with special inserts that will last the distance +44 (0)1844 275171

You can get a face miling cutter in a wide range of cutter diameter. What you want to do is balance 2 factors. First, the bigger the better. It will take fewer passes, and ideally maybe even a single pass, which is best for surface finish. Number two is the counter point to number one. You must respect the horsepower and rpm limits of your machine. The bigger the cutter diameter, the more power it takes. I will also add that spindle speed can be a limiting factor. In general, larger cutter diameter cutters have to spin at lower rpms, while smaller cutter diameters can spin at higher rpms.

The Button Cutter (also called a Copy Mill or Toroidal Cutter) uses a round insert and has many advantages of its own. Tough to call a winner with a Button Cutter versus these other Face mills, so click through and see about Button Cutters in their own right.

Now we see why the 45 degree models are so popular–that’s more than 40% more material removed. That’s definitely going to pay for the new face mill pretty quickly if you’re using it for very many parts.

It’s easy to compute Feeds and Speeds to compare these two face milling solutions using our G-Wizard Calculator software (click the link for a free 30-day trial if you’ve never played with G-Wizard).

First, end mills are generally smaller in diameter. This means it will take many more passes to do the job and all those passes will leave that many more marks on the work. The end result is end mills will take longer and they will have a much less fine surface finish.

By the way, round insert cutters are also called “Button Cutters”. We have an entire article about Button Cutters if you’re interested.

Both Sandvik and Kennametal will suggest the 45 degree cutter is a better bet for general purpose face-milling. The arguments given by these two for choosing the 45 are:

Be careful where you use 45 and 90 degree cutters. A workpiece that is not well supported, will deflect under a 45 degree cutter due to the high axial forces. A 90 degree cutter will produce a more consistent cut and the corresponding decrease in chatter will extend the life of the cutter.

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

18581906093

18581906093