Horn R114.1225.5.00 TN35 Grooving Insert - wintech grooving insert

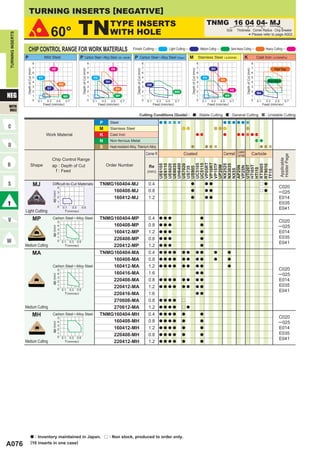

This document provides information on how to read turning insert standards. It is organized by insert shape and includes details like grade, application, recommended work materials, and cutting conditions. Graphs show recommended chip breakers and cutting ranges for different materials and applications, from finish to heavy cutting. Inserts are shown in order of negative or positive type, with breakers arranged from finish to heavy cutting. Specifications for individual inserts include size, grade, recommended uses and cutting conditions.Read less

THE ISO designation system for indexable insertsThe ISO designation system for indexable inserts (ISO 1832) is a standardized system to name an indexable insert.The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert. This system has several advantages:Unique naming of an indexable insert (supplier independent)All important features and dimensions are clearly stated in the nameSome code positions relate to the insert carrier in which the insert can be mounted It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system. This is an example for milling inserts. For other applications, you can refer to the relevant Machining Navigator. Do you want to know more?Contact Us Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert.

It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system.

18581906093

18581906093