How to choose a suitable corner radius for CNC turning inserts? - carbide insert radius

In just the same way that replacing threaded inserts is a straightforward process, removing them is equally straightforward. If you wish to see how to do this, please see below.

... shoulder milling in all steel and cast iron workpieces, stainless steels and difficult-to-cut materials The tool With Weldon shank Walter M4132 shoulder milling cutter ...

For a stronger thread, it ensures the bottom, top, and depth of the thread are all in the right places. Also, regardless of the thread profile, this will help eliminate any deburring. Due to the larger nose radius, fewer passes are needed compared to a V-profile insert. In addition, it allows you to thread more efficiently. For this reason, it is necessary to have a separate insert for each pitch and profile.

Full profile inserts are the most popular inserts. With this tool, the crest of the thread can be cut completely, as well as the thread’s profile.

The inserts have an external thread that resembles a coarse wood screw thread and an inside thread that resembles a fine machine screw thread. You can effectively use machine screws in wood with them, as they are useful for any item that will require the screw to be removed later. The threads of conventional wood screws are damaged when you remove them from the wood. If the line completely disappears from a wood screw hole, the screw will no longer be able to be fitted into that hole. Threaded inserts allow threaded machine screws, which is a more convenient method to accomplish this task.

... feed milling cutter, the MultiEdge 2Feed mini is used particularly for roughing small and medium-sized components. With a carrier program in diameters of 16-42mm as a screw-on milling ...

... productivity, performance and cost effectiveness required in specific applications. Shanghai Nagoya offers customized PCD milling tools for specific applications to meet production demands, and ensures ...

Inserts with threads on both the outside and the inside of the carbide threading insert are called externally threaded inserts. Generally, the inserts are threaded into a pre-tapped hole, or, in the case of some carbide threading inserts, the inserts can tap their own thread into a drilled or molded hole. Various types of anchorages are then used, including nylon locking elements, as well as other means.

... performance and cost effectiveness required in specific applications. For obtaining the screw threads with exact dimension in cutting procedures, SNSTC develops economic special tools to machine thread for all metal ...

When threading is necessary for your application, precise and consistent threading is paramount. Huana Tools offers an exclusive selection of high-performance threading inserts that will ensure 100% accurate threading every time. Huana Tools threading inserts are made of tungsten carbide for both standard and custom threading applications. Our threading experts are also ready to help you improve the threading of your products.

FinishLine Premium, the universal milling product by LMT Kieninger for semi finishing and finishing has been completely upgraded. New inserts with optimized wiper geometry have been added. For the user, ...

44° ONMX 1205 Face Milling Face Mills Indexable are cutting tools designed for machining large flat surfaces, primarily in milling operations. These tools use indexable ...

Unlike full profile inserts, multi-point inserts have more than one insert point (NT>1), similar to full profile inserts. If an insert consists of two points, the productivity is doubled. If an insert consists of three points, the productivity is tripled. As a result, the tool’s life is extended, productivity is increased, and costs are reduced since fewer passes are required. Because the cutting edge has a longer contact length, stable conditions are necessary due to the increased cutting forces. Besides being able to clear all the teeth, it also needs to have a sufficient gap behind the last thread for the insert to insert fully.

In the field of machining of spherical joints for the railway industry, the execution of semi-spherical radius offers a wide range of applications for special ball head milling cutters ...

{{#each product.specData:i}} {{name}}: {{value}} {{#i!=(product.specData.length-1)}} {{/end}} {{/each}}

APPLICATIONS Worldia PCBN Face Milling Cutter with indexable inserts used for finishing on end milling of cast iron,it can satisfy the demand for surface roughness ...

SMOXH Cutting Tools offers you quality, time, and cost savings simultaneously. Our tools, constantly updated with innovations every day, guarantee that quality doesn't have to come at a high price

43° SYNU 0704 Face Milling Face Mills Indexable are cutting tools designed for machining large flat surfaces, primarily in milling operations. These tools use indexable ...

This type of geometry is used for materials that are long in the chips. The product can also be used as a byproduct to strengthen stainless steel, alloyed steel, and non-ferrous metals. A machining geometry optimized for chip-forming to maximize the efficiency and precision of the process. The use of this geometry is not recommended for radial infeed operations.

These are suitable for sticky, work-hardening materials such as low-carbon steel, stainless steel, non-ferrous materials, and superalloys, to name a few. Their cutting edge is sharp, resulting in a high level of surface finish and low cutting forces.

Flat geometry provides overall functionality; it can be used to work with a wide range of materials. A round cutting edge adds strength to the cutting edge.

It can be challenging to fit the screw into the hole. Some screws include a hex socket built into the head. You can use flat blade screwdrivers with the slot. You can prevent the machine screw from moving by using the one you plan to use in the final fitting and attaching a locking nut. Once the insert nut is fully driven home, it can be finished with an impact driver. You can remove the machine screw by removing the nut with a small spanner. In addition to threaded inserts with heads.

The GlobalSpec SpecSearch database provides information about many different types of threading inserts. Most are described according to shape.

... includes PCD and PCBN lSO inserts as well as PCD and PCBN indexable end mills with corresponding inserts. Main Applications: Worldia FMP-BE milling cutters are ...

Shell-type milling cutter body for high-feed milling with Time-S-Cut indexable inserts (IC 8.5). Product features and benefits: With internal coolant-lubricant supply, ...

... automobile parts, but the machining of CFRP is facing issues such as burrs (fiber residue) and delamination. In particular, the final finishing of joints with other parts is sometimes performed manually, and more efficient ...

This video uses insert nuts with an outside diameter of around 8.5mm, smaller than those I am using in the video. The first hole should be 9mm in diameter for something like this. You can use softwoods as thin as 8mm if you need a tight-fitting. The manufacturer should always determine the pilot hole size. For drilling depths, drills are equipped with depth-stops. This is especially useful if you need to drill many holes at once.

Cutter and insert design optimized for finishing operations with high quality surface demands. High precision ground inserts and cutter body tolerances give consistent ...

... each and every cutting edge Cutter body has a special protective polished coating for uninterrupted chip flow and protection from corrosion and wear The inserts are available in ...

{{#each product.specData:i}} {{name}}: {{value}} {{#i!=(product.specData.length-1)}} {{/end}} {{/each}}

In terms of threading, externally threaded inserts are those with threads on the exterior, as their name implies. The threads have been internalized, but the external threads are also present. In this regard, I would like to know what this external threading is for. It is much easier to drive them into predrilled holes if they feature external threading since they can easily be driven into them.

... face milling cutter PFK88-SN is the milling system for rough milling when it comes to high removal rates, even in rough operating conditions. Characteristics Entering ...

circular thread milling bodies for face replaceable inserts Gr.C Technical details thread orientation: internal, external basic version: Zirk-GF - circular thread milling bodies type: face ...

circular thread milling bodies for 4-tooth indexable inserts Gr.11 Technical details thread orientation: internal, external basic version: Gigant - circular thread milling bodies type: 4-tooth ...

Universal indexable insert thread milling cutter Radius correction values: Walter GPS/Technical information TOOL Shank in accordance with DIN 1835 HB Multiple cutting ...

Whatever the thread pitch, profile or material, we can provide you with the solutions you need. The threading tools and inserts we offer help you produce quality threads for interiors and exteriors.

SMOXH Cutting Tools offers you quality, time, and cost savings simultaneously. Our tools, constantly updated with innovations every day, guarantee that quality doesn't have to come at a high price

... quality single-crystal diamond ball end mill can be used at speeds up to 100,000 revolutions per minute (RPM). It has a fine cutting edge and a low axis deviation. W.A.90 products will be available.

... " (12mm), the program offers versatility to cover many shoulder milling applications. • Left hand inserts with multiple corner nose radii for tailormade slot mills. • Fine pitch cutters ...

... cutter has been so developed, that by the most suitable combination of the cutting edges of different inserts, can perform the "full bullnose" profile machining in a single tooling machine ...

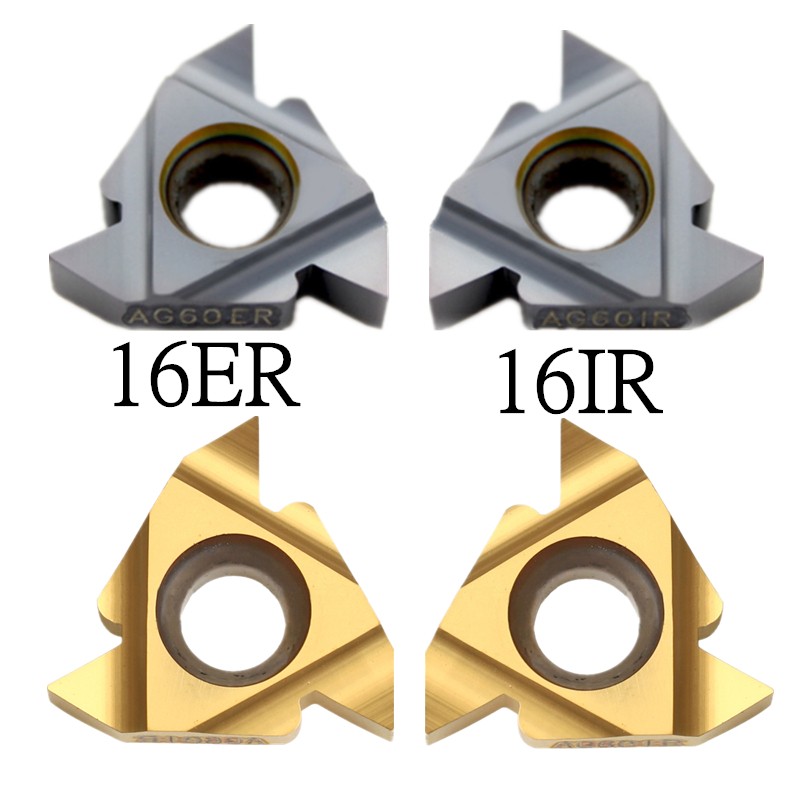

Some of the most common or standard angles for turning inserts include 55, 60, and 90. There could be some variation in these, but they are most frequently used. In addition, some common models of threading inserts include 16ER AG55, 16IR AG55, GC1125, GC1135, GC1025, 16er ag60 insert, 11er a60, 11ir a60 inserts, 16Ir ag60 insert and CB7015.

Once you know all the necessary details regarding threading inserts, you will now be able to use threading inserts in CNC threading more efficiently. It is important to remember all the steps mentioned above to give the best shot of Inserting the threads.

The term internal thread refers to a thread found on nuts or tapped holes, while the term external thread refers to one found on bolts, studs, or screws. The axial thread form is the name given to orientated threads that are oriented axially. There are three parts to a thread profile. These are the crest, the root, and the flanks.

Additionally, some inserts feature a nut wrapped around female threading that belongs to this kind of product; when a fastener is driven into the cage nuts, the tops of the nuts feature “wings” that dig into the object when the fasteners are driven into them.

There are several threaded inserts, each featuring a unique design, but they are all designed with female threading to support fasteners with male threading. A spiral design is a characteristic of circular threaded inserts, for example, and they are usually made of steel or bronze. The metal is coiled up in the appropriate size and shape to support the threaded fastener.

For thread turning, one of the most important considerations in choosing the correct insert geometry. Geometry affects many aspects of the tool life, such as chip control, insert wear, thread quality, and tool life in general.

Inserts with threads are an excellent choice for reinforcing threads on bolts and studs when they are frequently installed and removed. Choosing the right threaded inserts when working with weaker materials can provide a strong, durable solution.

... achieve secure indexing of inserts. ・ Secure insert indexing is achieved with rotation-prevention mechanism in 2 locations. ・ Improved attaching operability enables reliable error prevention. 03 ...

Among threading inserts, some have a single cutting surface, while others have multiple surfaces which can be used to continue threading when a tooth wears out. Several dimensions determine the number of sides and angles of the threading insert.

Ultra Hard Cutting Materials Cubic Boron Nitride (CBN) and all Diamond Cutting Materials: Monocrystalline Diamond (MCD), Polycrystalline Diamond (PCD), CVD-D Diamond.

3PKT 1505 Face Milling Face Mills Indexable are cutting tools designed for machining large flat surfaces, primarily in milling operations. These tools use indexable ...

Walter M4002 high-feed milling cutter Facts and advantages: High level of cost efficiency Reduced procurement and warehousing costs thanks to universal system indexable insert Four ...

SMOXH Cutting Tools offers you quality, time, and cost savings simultaneously. Our tools, constantly updated with innovations every day, guarantee that quality doesn't have to come at a high price

... PRO8 as modular milling systems with tangential inserts are designed for roughing and semifinishing operations in steel and cast iron. The program covers cutter bodies in the diameter ...

For removing spot welds from sheet metal. Exchangeable and double-headed milling crown. Adjustable milling depth with setting screw. No tearing of the sheet metal. No deformation of the sheet metal. Efficient ...

... times longer than other aluminum face milling cutter. High-precision pocket seat keeps 0.02mm axial runout without insert adjustment. It can be easily adjusted to 2μm axial run ...

... & Stability Give the Words "Chip Control" a new meaning Features and Benefits • 4-Edged Inserts • Higher Positive Radial Geometry • Larger Insert Screw With Deeper Engagement • Keener Edge/Higher Shear

Hardwoods, softwoods, and plywood all work well with press-in inserts because of their barbed exteriors. The well should be drilled so that the body of the insert will fit inside the hole. You can clamp the insert into place or tap it with a hammer and a block of wood. The drilling hole needs to be deep enough so that the epoxy engages only the tips of the insert barbs. This is especially important for applications where the clamping action tends to pull the inserts out of the wood, such as knobs on a drill-press fence extension.

High-Feed Milling - System MaxiMill HFC The high-feed milling System for extreme chip removal rates. |Advantages ▲ - Cutting depth of up to 3.3 mm ▲ - Soft eut with positive ...

There is no V-profile insert attached to the thread crests. Using the same diameter screw and nut is imperative before threading any screw or nut. This can be accomplished by turning the outer diameter of the screw to the same diameter as the inner diameter of the nut. Furthermore, it is possible to use the same insert for multiple pitches as long as the thread profile angle (60° or 55°) and radius are the same. As a result, the nose radius of the insert is smaller to cover the range of pitches, therefore reducing the tool life and creating Burrs on the tool.

Shanghai Nagoya is a professional manufacturing enterprise with production, development and design, marketing and customer service. We product specific customized tools and can also design for you to meet the processing conditions, ...

In softer woods and plywood, thread-in inserts are a good choice because their coarse outside threads ease the cutting process. You can then screw the insert into place by drilling a hole the right size for its body. White oak and maple are hardwoods, so drilling a hole slightly larger than the outside thread diameter and epoxying in the insert is recommended. If the insert is close to the edge of the part and screwing it in might split it, make sure to drill a hole slightly larger than the outside thread diameter. It would be best if you covered the end of the insert with epoxy to protect the threads inside.

Tool material: Solid carbide Standard: Manufacturer’s standard Type: N Helix angle: 40 Direction of infeed: horizontal, oblique and vertical Note: Standard application values for ap max ≤ 0.5×D.

... Mills have a sharp cutting edge by both high radial and axial rake angles and positive rake angle offering high toughness in a highly rigid integral body. The Fullcut Mill Arbor type corresponds to form FMH of the new ...

... indexable inserts a Irregular pitch for extremely quiet running a Perfect chip control, réduction of chip jams a Positive indexable insert geometries for soft cutting Indexable inserts ...

... round indexable inserts Irregular pitch for extremely quiet running a Perfect chip évacuation Positive indexable insert geometries for soft cutting Indexable inserts ...

... chatter suppression over symmetrical designs. Features Radial Rake Specially designed radial rake balances positive cutting action and edge strength. End grind features include a positive axial rake for high-performance ...

Special tangential combined milling cutter The length of the railway tracks and intersection points requires working on machine tools with a very long stroke. Particularly heavy (and expensive) in ...

18581906093

18581906093