How To Identify Indexable Inserts - milling insert cross reference - milling insert cross reference

This is only relative to the cnc side of the shop, but repeatability is one of the major benefits to a cnc machine and replaceable cutters that are dimensionally accurate from one cutter to the next supply this repeatability.

While the above reasons are good in their own right, there is an even greater reason that I can share and that is accuracy.

The early versions of carbide inserts were borrowed/stolen from the metal turning world and really didn’t stand up as a viable wood turning tool.

These tools cut effectively when the cutter and handle are presented with the tool in a horizontal plane, meaning parallel to the lathe bed.

For info on how we attack a lump of wood like the image above, have a read of this post titled “How to turn wood safely using faceplates“, and it is closely related to “how to turn a large display platter“. Both these articles dive into safety, whether carbide insert tools are used or not.

When it comes to bowls, some spindle work, and one-off pieces such as platters and the like I will always use HSS. No questions about it.

How often the wood turner is at the lathe may seem like a trite comment but if you think about it, the turner who seldom uses the carbide tool will have it last for years and this can alter perceptions and opinions causing the turner to think that the inserts last longer than reality.

It may seem like a long time on a calendar but when measured in MIW or miles in wood (revolutions of tool buried in wood) per insert the turner will likely be close to everyone else.

The internet is abound with stories of the difficulties and mysteries that surround this mystical tool so if using carbide inserts is what it takes to get fresh talent at the lathe then more power to it I say.

The uptake of carbide insert cutting tools has set the stage for many debates and arguments as to whether they are preferable and/or better than the HSS gouges and chisels or not.

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

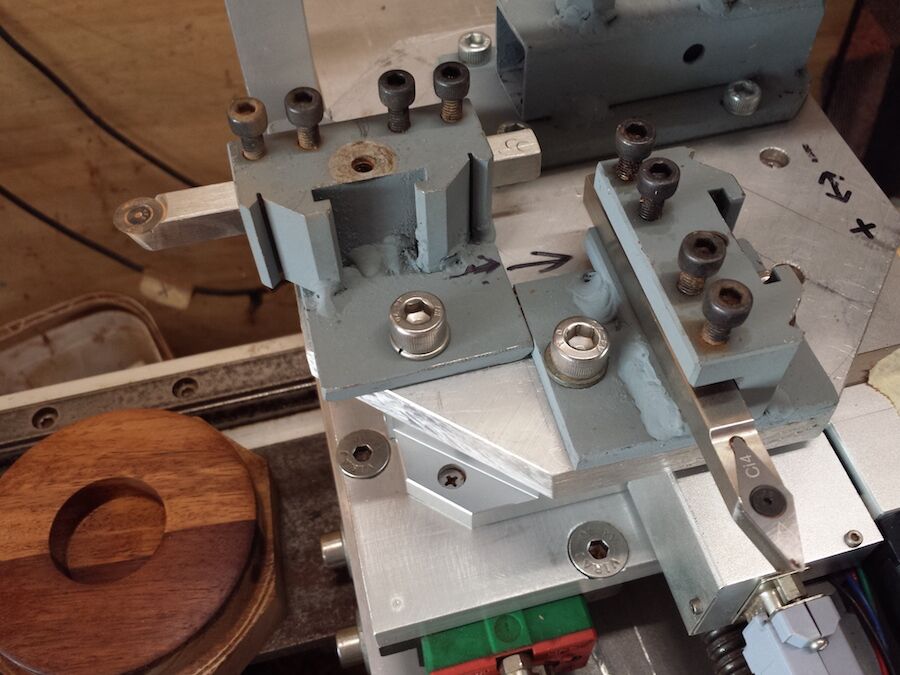

It is a homegrown cnc that is the subject of another article at another time but it is suffice to say that the carbide cutters of today have transformed the turning world upside down with the potential for small businesses to compete with much larger firms in the cnc space when smaller job lots are involved.

I have turned woods with HSS tools where I have left the grinder running beside me because the wood was so difficult to cut. Carbide inserts outlast everything else in these situations.

If the turner has to contend with just the rare piece of silica drenched timber and usually spins softer woods then the carbide insert will be with you for some time.

The HSS tools require the tool handle to have a handle down and tool tip up approach and that angle varies with the grind or angle of the cutting surfaces of that gouge.

There is one constant with wood-turning, and woodworking in general. This is the ability to sell your items to help fund your hobby. We have an article about “selling woodwork at markets, a beginners guide“. You might find something in there to help.

This is not to say that this is how we approach cnc work per se; as we only produce products for in house selling and don’t tender for outside jobs or work for the machine. It just allows us to utilize time far more effectively and efficiently.

Some of these ideas fell by the wayside while others have gained enough traction to present a solid case to be included in the wood turners kit.

Wood-turning is just one facet of life where progress is encroaching on established ways and the establishment stalwarts will always rail against change.

I turn several of the acacia species regularly and while the silica content can be high, depending on the log, the lack of dust is the main benefit.

Carbide inserts are one of the standout performers of the above process and they have come a long way in the last few years in terms of taking territory from the long established world of HSS tools.

The answer is no closer but we are hopefully a little more informed and my best guess is that this is a question that will never be completely answered to any level of satisfaction. Let the debates and arguments continue.

Hypothetically, every category would give us data on how long a typical turners gouge lasts in each of the categories, and the inputs for this calculation would be distilled down to a couple of criteria.

In other words, they were designed and are expected to be sharpened over an extended period of time/use/MIW whereas the carbide insert has been designed to be replaced.

For these, we would go back to the bullet point list at the top of the article and apply a relative multiplier that takes into consideration the factor of miles in wood.

However, I personally remain to be convinced that an insert can replace a well-shaped and sharp bowl gouge when shaping soft to medium density woods however I see good potential in very hard and dense woods for carbide.

Just for the record, I use both the traditional set of tools as well as tungsten carbide cutters or inserts, but I use them for very different reasons, as you will discover.

At a glance you might assume that is a game breaker and in situations like my cnc it certainly is, but there is far more to it than at first glance.

Even if the carbide cutters were to give a similar or better finish off the tool, the sheer pleasure of having ribbons of wood streaming at you or just past you off a well-sharpened gouge is just irreplaceable.

There is no requirement to make adjustments in the cnc code for tool wear. This is the game changer. HSS requires constant attention with sharpening equipment, and this shortens tool length all to prematurely.

Carbide cutters are incredible when you marry the attributes they have to cut effectively to a machine that can control the cutting pressure and the speed of the cut, and most importantly the angle that the cutter is presented to the work piece.

My experience of turning green wood has been that generally speaking the wood is easier on the tools but is marginal at best.

I cannot say if there is a measurable benefit for a tool to retain an edge or not with green wood but the tool tip temperatures are noticeably lower so that has to be a factor to consider.

With carbide inserts, looking through purists’ eyes they could be just a replacement for the traditional scraper; but that is far too simplistic. The early cutters were just that, a flash scraper that was good at rough work and hopeless at detail or finish work.

Every damaging factor to a cutting edge is present when dry hard wood is turned so carbide will shine here if care is taken with speed selection and dust control is in place.

Since the mid to late 1990’s when I began turning wood, the tools and technology available then have been under siege from a constant wave of new ideas and methods that have promised to replace the old ways of doing things.

The counter argument to the above is more of a philosophical one; in that we turners, as a collective, are at risk of losing skills that have been generations in refining.

Thank you for supporting a family owned small Australian business. We strive to offer world class products that meet the standards of every visitor in an environmentaly sustainable way.

This image is a Ravioli Pin with tapered ends that are easy on the hands as you roll and is an example of how we use carbide inserts. We utilize the round cutters to create the pockets leaving a great finish straight off the tool; and when the cutters are fresh we can often start sanding at 240 grit sandpaper and as the cutter becomes dull we drop the grit as needed. When we need to use 120 grit it is time to rotate the cutter and start fresh again.

It took a while for the carbide manufacturers to realize the depth of the woodworking market but once they discovered that there was a ready audience waiting for something to help with tools that will hold an edge for longer, then the wheels started turning and here we are.

After years of practice I know I can trust and understand what the tool is telling me. It’s the shape of the shavings, the feel of the edge slicing fibers, and the sounds. These are irreplaceable to me.

That rugged root ball that shows potential of a spectacular thin-walled hollow form with wall cavities and hollows is a prime case of harboring far too much of this mineral that seems fair or necessary. The things we turners put up with!

Contrary to HSS and the angle of presentation to the wood that the classic bowl gouge requires to achieve a reliable cut, the carbide insert runs completely counter to that practice.

It is a major selling angle of the biggest names in carbide insert supplier’s advertisements and quite correctly too as these inserts give a level of confidence to the novice turner that a bowl gouge cannot give.

The skill level of the turner plays a huge part in the life expectancy of every tool be it HSS or carbide, and it can be reasonably safe to say that the experience level, or lack of, has been the biggest driver of the technological push in these inserts.

Maybe I am a traditionalist and one could argue that I have my head in the sand and am ignoring progress, but read on to see why I think these carbide inserts are such terrific value and in certain situations, they cannot be beaten with HSS.

It doesn’t take long to work out that there are far to many variables involved to come to any sort of a definitive answer.

If the turner has a practice of collecting wood from beaches or from flood washed zones then this wood turner will consume more carbide inserts that someone who deals only with clean wood.

The inserts go some way to addressing a problem, and that problem is the edge holding capacity of a tool and the experience required to use the existing tools safely and effectively.

How often this type of wood is turned will determine the life of the cutter, and long sessions at the lathe with heat buildup at the cutting edge will take some toll.

So in closing, I would say that inserts have a place in the turners’ collection and can be a benefit where negative rake scrapers are concerned and in fact the inserts should and do shine here.

So in a fair comparison this needs to be considered and calculated into the argument. The question to be asked in any discussion about how long do carbide inserts last is this; compared to what!

The HSS tools like the bowl gouge cannot or have not been replaced at all with these inserts in some situations. It is difficult to imagine a carbide cutter giving the feel and touch that the bowl gouge gives, especially on long cuts in soft wood.

18581906093

18581906093