IMTS 2016 Preview: Tooling & Workholding - ball nose milling insert

To summarize, Y-axis turning is a method for simultaneous three-axis turning with interpolation of the milling spindle axis. The new tools can also be used in “static mode” with a locked spindle for flexible two-axis turning with fast insert indexing. The method is suitable for all materials and requires a multitask machine with options to allow interpolation of the milling spindle axis during turning.

SANDVIK COROMANT has developed two new tools to support a new turning method – Y-axis turning. The new CoroTurn® Prime variant is recommended for turning shafts, flanges, and components with undercuts. The CoroPlex® YT twin-tool, featuring CoroTurn TR profiling inserts and CoroTurn 107 round inserts with rail interface, can be used for components with pockets and cavities.

Both T3225 and T1215 are CVD-coated grades with superior wear resistance plus improved fracture toughness, to ensure stable, long tool life and effective high speed machining. T3225 is suited to steel and stainless steel milling, while T1215 is ideal for cast iron machining.

The ability to machine several features with a single tool reduces cycle time, and no tool changes are required, which minimizes the risk of “blend points,” or irregularities between adjacent machined surfaces. The main cutting forces are directed into the machine spindle, thus improving stability and reducing the risk of vibration. A constant entering angle drastically improves chip control and makes it easier to avoid chip jamming.

The technique makes use of the Y-axis, and all three axes are used simultaneously when machining. The tool rotates around its own center, the insert is placed for machining in the Y-Z plane and the milling spindle axis interpolates during turning. This allows intricate shapes to be machined with a single tool.

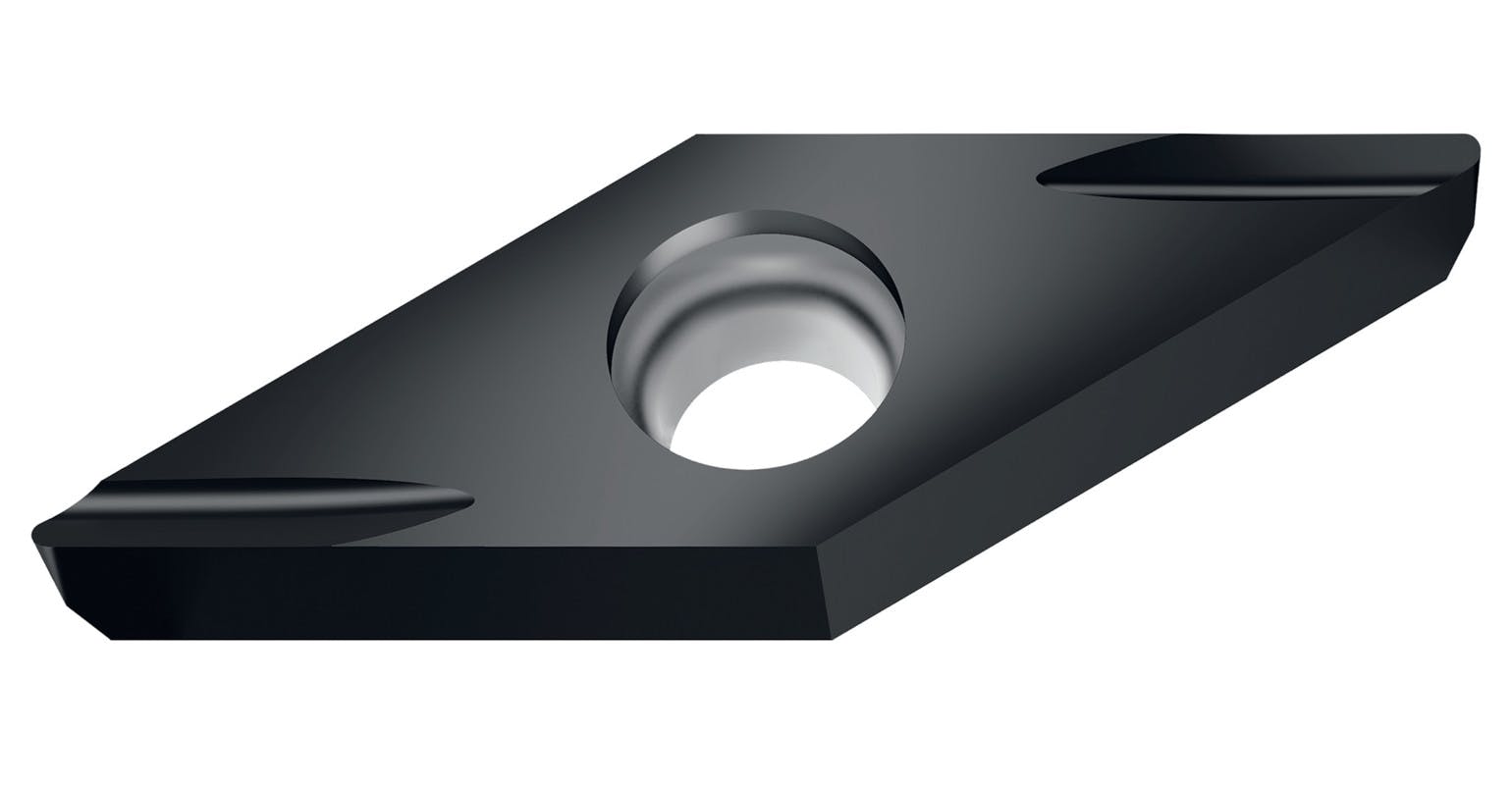

Tungaloy has added new high performing CVD- and PVD-coated grades to enhance its milling product families, including the DoPent face-mill line and Tung-Tri square shoulder mill series.

AH3135, a PVD-coated grade for milling applications, consists of a wear-resistant PVD coating over high fracture toughness carbide substrate – a combination designed to withstand fracture and wear. AH3135 is a universal grade, effective in face, shoulder, as well as high feed milling of various types of materials.

“One could say that these advances, together with progressive capabilities in modern machines and CAM software, have paved the way for the new Y-axis turning method,” explained Staffan Lundström, product manager, Turning. “And with the tools and method now in place, we look forward to exploring the possibilities this method can present to our customers.”

18581906093

18581906093