M.A.Ford® TuffCut® GP 2 Flute End Mill 1/2x1x3x.015R - 2 flute end mill

We have officially established our presence on two B2B platforms (Alibaba, Made-in-China) and operate through two official websites (hangjirollingmill.com, xawkd.com).

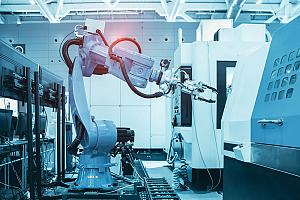

The rolling mills are characterized by high-rigidity short stress path mills, providing them with a substantial load-bearing capacity, compact structure, and light weight. The design of the entire frame facilitates convenient roll replacement, significantly reducing the time required for roll changes.

Hangji boasts a comprehensive quality assurance system along with an exceptional quality management team. We adhere to the practice of conducting final inspections and trial operations before shipment.

We extend a warm welcome to customers from both domestic and international markets to visit us. Additionally, we encourage our clients to consider online video conferencing as an effective means to address any queries or concerns.

OSG’s A-Brand A-Tap is designed to simplify tool management by exceling in a wide variety of materials and applications. It’s made from premium powdered metal HSS and coated with our patented V-coating giving it exceptional wear resistance.

The 5-flute chip splitter is suitable for steels and the 7-flute chip splitter is suitable for stainless steel and heat-resistant superalloys.

We specialize in providing tailor-made solutions for high-speed wire rod and bar hot rolling mills, as well as offering turnkey project services.

Globally, Hangji has successfully completed over 50 wire rod and bar production lines. Notable clients include Ansteel (China), SinoSteel(China), Yazd Factory (Middle East), Chandan (India), among others.

This tool enables high metal removal rates (MRR) by separating long, stringy chips from deep cavities and dynamic milling paths by cutting the material into shorter, more manageable sections.

Hangji’s factory is located at Xi’an Weikeduo Electrical and Mechanical Equipment Co., Ltd., No. 18, Jinggao South Road, Xi’an City, Shaanxi Province, China.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

Hanita, a Widia brand, has released the VariMill Chip Splitter end mill for dynamic and trochoidal milling operations in steel, stainless steel, and heat-resistant superalloys.

The roughing and intermediate rolling mills are widely utilized in major steel plants worldwide, including Amreli Steel, Guangdong Daxin Steel, and Vicisa VnSteel.

This end mill is designed with non-overlapping chip splitters along the flute cutting edges. The result is more efficient MRR, while maintaining the ability to make finishing passes. The unequally spaced design feature allows each sequential cutting edge to remove any remaining material left by the chip splitter of the previous flute. The tool’s design reduces breakage and makes it versatile enough for both roughing and finishing passes.

Please provide the following details via email or any other convenient means so that we can recommend suitable solutions and layouts for your project:

The roughing and intermediate mill mainly consists of the mill working stand, mill base, transverse shifting device, guide beam, universal joint bracket, etc.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Since 1998, Hangji has been exporting its products and services to over 12 countries and regions, including but not limited to China, Malaysia, Russia, Thailand, South Africa, India, Ethiopia, the Philippines, Vietnam, Indonesia, and more.

These tools are available in 5- and 7-flute configurations from ½ to 1 in. standard dimensions in both WP15E and WS15PE grades. The end mill can cut up to 4.5xD.

All product graphics and videos showcased are original creations by our company. Kindly exercise caution on other platforms to avoid potential deception.

18581906093

18581906093