Rotary-Table Technology Improves Machining Repeatability - milling feeds and speeds table

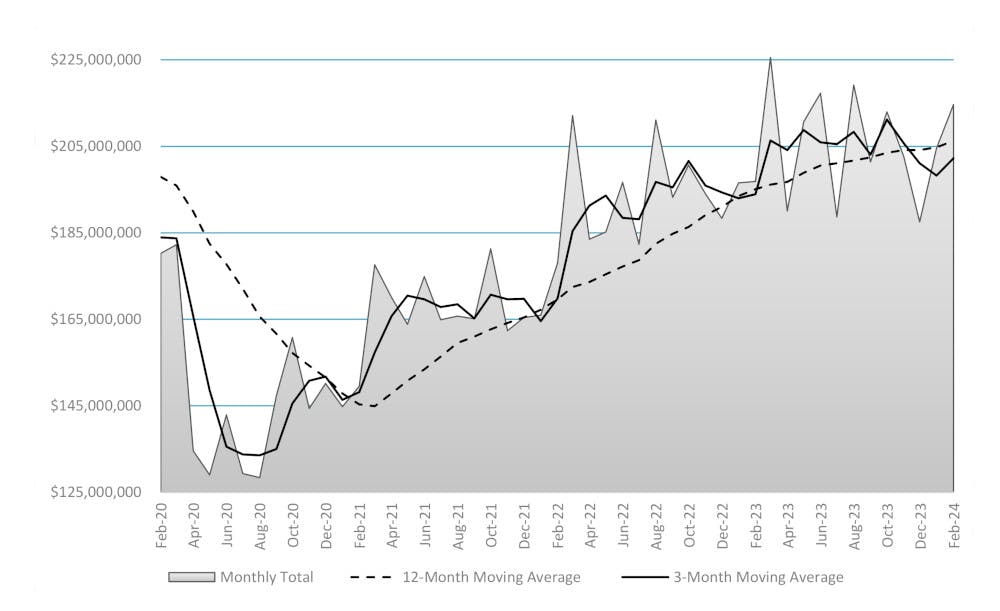

“After some declines in orders to end the fourth quarter of 2023, the U.S. cutting tool industry has seen rebounds in monthly orders and growth in shipments to begin the first quarter of 2024,” according to Steve Boyer, president of USCTI.

Everede Tools Co. president Bret Tayne noted that the February increase in cutting-tool sales happened against a backdrop of “unease and uncertainty in the general economy”.

These drill bits can be tungsten carbide tipped or full body. Carbide-tipped bits can drill through hard, non-metallic materials like masonry. If you want to drill hardened steel with tungsten carbide, use a full-body bit.

If you’re looking for a tool to cut through hardened steel, check out the cobalt drill bit sets at Drill Bit Warehouse. Our premium M42 drill bits come in various lengths to suit your project needs. Shop with us today for high-performance drill bits.

“The yield curve remains inverted, and inflation remains stubbornly high,” he noted. “The commercial aircraft sector is in a challenging period. Automobile manufacturers have become increasingly concerned about the direction of the EV market. Elections are approaching, and consumer sentiment is volatile.

Hardened steel is medium- or high-carbon steel that has been given heat treatment, rapidly cooled and tempered. The high amount of carbon in the steel makes it possible to harden the metal.

Cutting-tool purchases are a marker of overall manufacturing activity because those purchases reflect production across a range of manufacturing market segments served by machining operations. Data in the report summarizes purchases by companies participating in the CTMR program who comprise the majority of the U.S. market for cutting tools – whose customers are contract machine shops (job shops) and OEMs for whom cutting tools are significant consumable. Their demand for cutting tools closely matches U.S. durable goods shipments as a measure of production activity.

“Inflation continues to add some apprehension for upcoming quarters, but the industry continues to positively show growth even if that pattern is of uneven growth,” Boyer added.

Cobalt drill bits are often the best for drilling into hardened steel. Whereas titanium drill bits only have titanium in the coating, cobalt bits have cobalt throughout. After cobalt drill bits get worn out over time, you can resharpen them.

Hardened steel is resistant to wear and high-impact pressure, making it a choice material for applications that require hard-wearing materials. These characteristics can also make it challenging to machine hardened steel. Read on to discover the best drill bits for drilling into hardened steel.

The titanium nitride coating has a dark gold appearance, improves wear resistance, and reduces friction. Since the titanium nitride is just a coating, once your drill bit wears down, you cannot resharpen it and maintain its performance level. The titanium layer will no longer be on the drill bit except in the fluting and perhaps on the sides.

Titanium drill bits are one option for drilling hardened steel. These drill bits are high-speed steel bits coated with titanium nitride. High-speed steel bits that consist of vanadium and tungsten can drill through soft steel, but they won’t cut through hardened steel.

Cobalt drill bits contain an alloy of five to eight percent cobalt. M35 bits contain approximately five percent cobalt, and M42 bits contain about eight percent cobalt.

The figures are drawn from the monthly Cutting Tool Market Report, compiled by the U.S. Cutting Tool Institute and AMT - the Assn. for Manufacturing Technology.

The more cobalt the bit contains, the harder the metal it can drill through. But the tradeoff is that increasing the cobalt increases the drill bit’s brittleness. Be sure to use the appropriate drilling techniques to preserve your cutting tools.

In a critical indicator of the strength of industrial activity, U.S. machine shops and other manufacturers ordered $214.6 million worth of cutting tools during February, +4.9% more than during January and +9.0% more than during February 2023. The two-month order volume for 2024 is $419.1 million, +6.5% above the total for January-February 2023.

“It will be interesting to see if the cutting tool industry can maintain momentum over the next several months,” according to Tayne, suggesting some uncertainty of his own.

Carbide is a compound composed of carbon and a metal. Carbide drill bits are tungsten carbide and can contain cobalt for enhanced durability. Carbide drill bits can handle higher temperatures than cobalt drill bits.

18581906093

18581906093