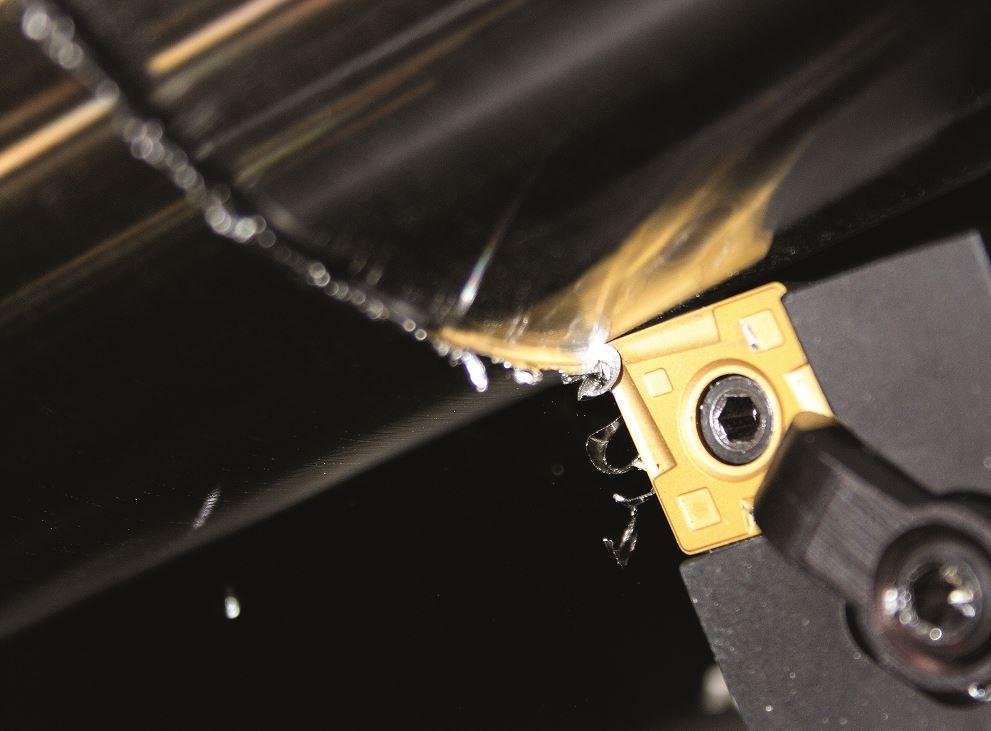

Concave helps squeeze more grain from combine - concave carbide insert

The evidence against GE became indisputable. As Judge Knox noted in his decision: “The defendants, by their counsel, have frankly admitted that they were monopolists and that they sought to prevent price competition.” He found the company guilty as charged. He then practically apologized for making the verdict and sentence by stressing that since the offenses of which GE was guilty were eight or nine years old, he personally had “a very strong indisposition not to punish stale crimes too severely.” The judge then turned down the government’s request that the defendants be given a six-month prison sentence. Judge Knox imposed fines totaling $56,000 against the corporation and the individual defendants. He stated that a failure to impose any punishment at all “would be misinterpreted by many people.” The government’s attorney, at one point, stated that the business community regards fines in antitrust cases as “a license fee, which may be charged off as part of the cost of doing business.”

“The other thing to think about here is a directional force,” said Andersson. “In the finishing stage, you want to put as much of your force as you can axially along the component, because that will give you the stability needed. Choosing an insert that offers as close to a 0-degree entry angle will give you more force along the axis, but you also need increased back-clearance of the insert to get that quality surface finish.”

Anna Marie Taylor: James Lerner, the author of this book, is the father of my partner of more than 30 years, Richard Lerner. We frequently traveled from California to Brooklyn, New York, to visit his parents, and I got to know them well. After Jim retired in his early 70’s, Richard encouraged him to write his memoir because of his involvement in some of the most critical events of the 20th century. These included the antifascist movement in the United States, of which little has been written, and the surge of the industrial labor movement during and after World War II.

“With finishing you're going to be using the higher surface footage, so faster speeds with lower feed rates,” said Matt Goss, applications engineer and project development, Greenleaf Corp. “And, generally, you're going to have a smaller depth of cut. But it's also important that you make sure the feed rate coincides appropriately with your desired surface finish. If you're using too light of a feed rate, it can cause excessive rubbing and premature wear of the insert, which is going to lead to poor surface finish.”

“Wipers are so useful during the roughing and even medium stages of the turning process,” said Andersson. “When we think of wipers, we automatically think of finishing operations, but they are used to generate good surface finish in other parts of the process.”

The following excerpt is a particularly compelling account covering the GE-Krupp Conspiracy Trial in 1947. It details how GE and German manufacturer Krupp colluded during WWII to maintain a worldwide monopoly on the valuable war material tungsten carbide. It reveals the depth of GE’s Nazi past. Lerner was the only journalist to cover the trial in 1947. As Lerner told union members through a story in the UE News: “If you don’t see anything about the GE-Krupp cartel trial in your local newspaper, don’t be surprised. There’s no one at most sessions of the trial to report it. One day there were two commercial newspapers and UE News; the next day, one commercial newspaper and UE News. Today only UE News was left.”

“This creates a sharper edge for the insert, which allows it to more efficiently and effectively shear the material during the finish operation,” he added. “Ceramic inserts typically don't have chipbreakers; instead we look at the cutting edge preparation, which is usually a combination of lands and hones. For finishing, we recommend an insert with a smaller land, and a sharp edge with no hone if the material is softer. However, for any material 50 Rockwell C or higher, we typically lean towards an insert with a light hone on the cutting edge to help provide a little bit more protection and keep the edge from chipping.”

Lest anyone imagine that corporate crimes being unreported by the mainstream media and punished with a wristslap are anything new, legendary labor reporter James Lerner’s account of the GE – Krupp conspiracy trial of 1947 is an eye-opener.

General Electric defendants were visibly shaken when the witness opened the lock on his leather bag and began pulling out file folders. U.S. Attorney Malcolm A. Hoffman, who was in charge of the government’s case, let me examine those documents in his office several floors above the courtroom. The memory of the war’s horrors was still vivid in my mind as I read letter after letter from Krupp to GE officials ending with the phrase “Heil Hitler.” I thought of concentration camp scenes that Allied armies had found in Germany, of the millions of people, including my own relatives, who disappeared forever into Hitler’s death camps. By this time, the world knew that Krupp had run some of the camps where slave laborers produced goods for Nazi armies. In defense of its arrangements with Krupp, GE claimed that its tungsten carbide deal helped create jobs for American workers. Evidence showed, however, that the cartel arrangement actually resulted in job losses.

The experts agree that tooling and fixturing play significant roles in achieving a quality surface finish. If fixturing is not rigid, it can lead to chatter, which could compromise the finish. It’s also important to make sure the toolholder has the shortest possible hangout to help keep it rigid. The workpiece and cutting tool should be adequately supported so that there is no vibration during the finishing operation.

“If you look at a green-state machining or soft steel turning machining, the operator needs to produce a good enough surface finish in early stages to achieve the necessary surface in finishing,” said Andersson. “If you start looking at hardened steel components, the surface finish of a roughing pass before heat treating will tremendously impact the final surface finish that can be produced after heat treating.”

A toolholder pocket that is too open can reduce the contact area between the insert (for example, with WNMG inserts) and the pocket, which then introduces movement into the pocket. This leads to microvibration, which has a negative impact on surface finish. YG-1

Andersson pointed out that many shops tend to drop the speed compared to roughing applications, which is a common mistake for finishing operations. Increasing the speed is necessary to achieve a quality surface finish.

“When it comes to a physical vapour deposition (PVD) versus a chemical vapour deposition (CVD) coating, the CVD coating tends to be much thicker than a PVD coating,” said Andersson. “With a thicker coating, you are going to have a greater challenge of producing a quality surface finish than with a thinner coating, and this holds true every single time. PVD produces a better surface finish than a CVD coating because of coating adhesion. A PVD insert will have full coating on all surfaces of the insert, whereas CVD will have reduced coating right on the microgeometry, changing the shape of the microgeometry.”

Andersson added that force management is a significant factor when it comes to the finishing stage of turning operations. The tangential force, which is axial force plus radial force, can be treated as a constant in turning. If operators increase the axial force, they reduce the impact of the radial force, which allows them to hold better tolerances and reduce microvibration because of the reduced natural instabilities. He added that this is not necessarily as much of a consideration during the roughing and medium stage of the process.

For me personally, my favorite chapter is “I Cover the GE-Krupp Conspiracy Trial.” because it reveals an important trial in US History that was ignored by the mainstream press and whose lessons of profit over national security should never be lost.

“Chip control is essential because with this process, we need to use the chip area for thermal evacuation,” said Andersson. “You have to raise the temperature so that it is both high and even, but you also need sufficient chip area. If you reduce the chip area, there is less mass to transport that heat away from the cutting zone and you will start seeing the effect of chemical, flank, and crater wear on the insert. Chip control really becomes a challenge when you're looking at surface finishing. So that's why you have to select the right geometry and maintain proper cutting parameters for a given application.”

To ensure a high-quality surface finish, operators need to take off the right amount of material in the roughing and medium stages so that finishing can take place with few or no errors. Any issues during earlier stages can lead to poor surface quality.

Jan Andersson of YG-1 and Matt Goss and Paul Lobsinger of Greenleaf Corp. offer some tips that can help operators improve turning finishes.

We have only 24 hours to raise $21,000 for Truthout. Independent journalism is a pillar of democracy, and we rely on your support to make our work possible. Please make a tax-deductible donation now.

If you don’t see anything about the GE-Krupp cartel trial in your local newspaper, don’t be surprised. There’s no one at most sessions of the trial to report it. One day there were two commercial newspapers and UE News; the next day, one commercial newspaper and UE News. Today only UE News was left.I thereby sat there as the only reporter remaining to hear the full story of the partnership between GE and Krupp, its German partner. I could not help thinking what a field day the press would have had if union leaders were under criminal indictment instead of corporations.

What do you think James Lerner would think about the state of investigative and political reporting today?

Trial testimony showed that smaller competitors were either driven out of business or forced to go along with the price set by the monopoly. Methods used to accomplish this, according to witnesses, such as the president of the Union Wire Die Company, included forced buy-out of competitors. The head of American Cutting Alloys testified that he begged GE not to drive him out of business.

What are your favorite chapters in the book? Is there a particular one you feel exemplifies his life and work particularly?

After the opening days of the trial, I was also the only person in the courtroom who was not directly related in some way to the proceedings. I must have been conspicuous for my diligent presence, especially since I took extensive notes day after day. The defendants tended to ignore me even when I sat directly behind them to catch their comments. However, GE did not ignore what UE News would say about the case. Shortly before the trial was to begin, we ran a full-page story on the salient facts of the case based on the 160-page indictment. The company accused the union of printing “unproved charges of the indictments as facts” and of being antilabor because we were harming this great benefactor of the working man by printing such charges. This condemnation of UE News was distributed to all GE workers in the corporation’s own newsletter, Work News (February 7, 1947).

“A larger radius is typically preferred in finishing so long as the part geometry allows for it,” said Goss. “The larger radius helps to more efficiently smooth out the material and acts almost as a wiper. With a larger nose radius, you can up the feed rate slightly while still maintaining that high surface quality. In thin-walled applications however, a smaller nose radius will reduce radial cutting forces, which may lead to deflection and vibration that can negatively affect surface finish.”

Truthout doesn’t take corporate funding – this lets us do the brave, independent reporting that makes us unique. Please support this work by making a tax-deductible donation today – just click here to donate.

A brief item in UE News of September 7, 1940, a few weeks after I joined the paper’s staff, reported that two federal indictments were returned against the General Electric Corporation and the Krupp Armaments Works of Germany for conspiring to maintain a worldwide monopoly in production and sale of carboloy, a trade name for tungsten carbide. The government suspended its prosecution of the case at the outbreak of World War II. It was only seven years later at the war’s end, that I began to understand the full significance of these indictments.

Journalists supposedly try to be objective in their reporting – yet Lerner has a genuine political affinity with much of his subject matter. What do you think he would say about this issue?

I saw Jim’s drafts in many forms over a number of years. We used to all sit around the kitchen table in Brooklyn for hours on end, reviewing the ongoing writing and listening to Jim embellish stories for our benefit. Dick especially would often ask probing questions and make suggestions. Jim was very aware that the work needed more editing and gladly accepted when I decided to offer to work directly with him as a coeditor with Dick. During his lifetime, at his request, I was able to organize and edit some specific chapters that he wanted to give to family and colleagues. My goals in editing the manuscript became defined over time. They were to keep the narrative accurate, flowing and readable without changing the feel of Jim’s wry commentary and sense of humor. This meant eventually reorganizing some of the material into fewer chapters and adding a certain amount of transitional writing. It also required moving some very detailed material into notes and adding an index.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

Using wipers allows for increased feed rates, within the appropriate range for the finishing stage, while reducing the contact time, meaning longer tool life. The higher feed rate also leads to better chip control and evacuation, which helps to improve surface quality.

“The direction in which the tool is cutting can also be important to pay attention to,” said Lobsinger. “You want to make sure that you are directing the forces of the operation into a well-supported portion of the part; machining away from the support can lead to vibration, which can also affect tool life, and your surface finishing will definitely be compromised.”

Jim never thought of himself as “objective” in the sense of purporting to present all sides of an issue. He considered himself a labor journalist, whose job it was to truthfully provide and analyze local, national and international news in a way that would be relevant to working people and that would advance their welfare.

In the winter of 1957, I sat in for several days at another trial involving GE. This trial was in the same federal courthouse where I sat through the GE-Krupp case many years before. Now every seat was taken and all the trial details were extensively reported in the tabloids, with photographs and drawings. GE officials were accused of transporting prostitutes from New York City to Newark, New Jersey, to entertain prospective GE customers. At UE News we decided to ignore the story. The sordid activities of individual corporate executives seemed insignificant next to the great crimes of corporate monopolies during the war that were flagrantly ignored by the media and public leaders.

“Coolant helps keep the part and the tool cool so you can cut at faster speeds,” said Goss. “If high-pressure coolant isn't available, conventional or flood coolant would be the next best option.”

At UE News, Jim began by reporting on stories of interest to union members, often reporting on-the-ground at work actions and strikes or writing about people’s everyday lives. Jim also started the pithy and often humorous column called “It Happened This Way” that ran from 1948 to 1986. The column became well known for its barbs at corporate actions and misdeeds that affected workers.

In 1933, when he was 22 years old, Jim joined a new organization called the American League Against War and Fascism and became one of its principal organizers. He traveled throughout the US and Canada to form local chapters of the League.

Lindsay Luminoso, sr. editor/digital editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Jim was one of the original students at the Experimental College at The University of Wisconsin, Madison. The college was known for its innovative teaching model.

Movement on the insert also makes it difficult to maintain dimensional tolerances on the component. The pocket should be suited for the insert and kept in good condition. There should be no wear or deformation, as even the slightest movement has consequences.

Andersson noted that one overlooked aspect of this process is how the insert grade, particularly as it relates to coatings, affects surface finish.

Having withheld the details of the GE-Krupp conspiracy throughout most of the trial, the New York Times carried on its front page a story about the AEC action against the union. The court verdict against GE, on the other hand, was reported on the entertainment page alongside advertisements. It was the height of irony that the very union that was praised by civilian and military leaders for its outstanding role in helping the United States and its allies defeat Nazism was now the enemy.

The mainstream media saw movements for change from the same perspective as the industrial corporations. Their coverage of peace and labor union organizing, court cases, etc. was therefore highly selective and clearly conformed to their own economic and political interests.

Jim was a modest, down-to-earth person. Despite the fact that his work required a lot of travel, he was basically a homebody. He loved his hobbies, which included carpentry, and photography and raising bromeliad plants. He was married to his wife Gertrude Fisher for 65 years and kept in frequent touch with his parents, children and extended family. Above all, he loved to tell stories.

This book is important if it is true that we can learn from our history. It is especially valuable because Jim documents how on-the-ground, persistent and fearless commitment by broad-based movements for social justice matter during times of great political change and conflict. Jim conveys this history with personal stories of everyday, often behind-the-scenes events. This history still has meaning today for social justice movements in the age of Occupy, Google, Facebook and Twitter.

Faster cutting speeds help raise the temperature slightly, which generates a better surface finish. It also prevents that material from sticking to the top or the face of the insert. Greenleaf

Lobsinger added that in cases where the operator runs into chatter, varying the RPM cycle, where the SFM varies between low and high, can help get rid of or at least reduce harmonics. This programming tip can help improve turning finishes.

How did GE influence the press? One day at the carboloy trial, I saw defendant William G. Robbins reach into his pocket for his wallet and remove a clipping that he passed around to other defendants with obvious pleasure. Leaning forward, I could see that the clipping dealt with the indictment of Carl Marzani, who had made a film for UE called Deadline for Action (1946). The film offered an exposé of monopoly practices, including the tungsten carbide conspiracy. Marzani was tried and convicted on charges that he denied being a member of the Communist Party and had falsely signed a loyalty statement. He served 34 months in federal prison.

In 1961, GE and Westinghouse and some of their officials were found guilty of conspiring to rig bids on the sale of turbines. Following the verdict, attorney Malcolm A. Hoffman, who had handled the government’s case in the tungsten carbide suit 11 years earlier and who had permitted me to examine the Krupp letters, wrote to the New York Times. He described how his request for jail sentences in the GE-Krupps tungsten carbide case had been rejected by Judge Knox. Hoffman noted that following that case, the United States subsequently brought 36 anti-trust suits against GE. In 1985, the corporation pleaded guilty to defrauding the government on missile-warhead contracts. This time, the court imposed a fine of $100,000 and $2 million in criminal and civil penalties.

Using the best insert for an application helps to produce quality cuts. Speaking with insert manufacturers about new applications can help determine which insert will produce a quality surface finish in turning operations. The machining conditions and component material determine what type of insert is appropriate, but some general features can be recommended for the finishing stage.

When you came upon James Lerner’s manuscript, what kind of shape was it in? How did you pull together the narrative?

“Shops need to think about the turning process as a complete chain,” said Jan Andersson, director, product management, indexable inserts for Americas, YG-1, Vernon Hills, Ill. “It’s important to think of all the steps, from the roughing all the way through finishing, because they are all connected, interlinked, and interdependent.”

The U.S. government charged that in 1938 the American and German firms agreed to divide up the world market for carboloy. Before the agreement, the product sold for $48 a pound in the United States. After the agreement, GE set the price at $453 a pound or one dollar per gram. The prosecution showed that under the agreement, Krupp would control the sale of carboloy everywhere in the world except the United States and Canada, which were GE’s turf. Government prosecutors refuted GE’s claim that its expertise and patents were the sole reason this valuable material was available to American industry. The government brought to the witness stand a parade of businessmen who testified that they had been producing and selling tungsten carbide before the GE-German agreement went into effect.

GE’s attempt to monopolize patent rights for tungsten carbide was undercut by a document found in its Schenectady files and presented as evidence. This consisted of a letter that was dropped into the company’s suggestion box at its Schenectady, New York, plant by W. L. Merrill, an engineer in charge of the production of tungsten carbide. Merrill proposed that the material be sold for $50 a pound instead of the $453 set by the company. He wrote in the letter:

“This is especially important when we start getting into the superalloys,” said Andersson. “Many industries, like aerospace manufacturers, require the use of G- tolerance inserts versus M-tolerance inserts in finishing. The quality of the microgeometry of a G tolerance insert can really impact the surface finish, and this will help not only industry-specific applications, but anyone looking for the high-quality surface finish in difficult-to-cut materials.”

“The best way to produce a good surface finish is to start with the insert manufacturer and look at the cutting recommendations,” said Andersson. “It will give a good starting point. You can make adjustments along the way, but the recommendations are based on years of R&D and shop knowledge, so take advantage of the expertise.”

“One of the government witnesses at the trial explained how a tool edged with tungsten carbide could be used 1,000 times before it had to be reground compared to only 100 operations using other tools. The indictment also cited tungsten carbide’s superiority in parts for lathes, drills, saws, and other devices used in the production of military equipment and automobiles.

Microgeometry and edge line condition of the insert have a tremendous impact on the initial chip formation and surface finish.

However, Goss noted that coolant is not recommended for all applications. For turning hardened materials -- anything over 50 Rockwell C, using a ceramic insert -- coolant should be avoided, as it has a tendency to thermal-shock the insert, which can lead to fracturing. But if the material is on the softer side, coolant can be used with a ceramic insert.

I also love the last chapter, “Vietnam is Union Business” because it describes the courage that UE consistently showed to openly oppose the Vietnam War long before it was popular to do so.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

Lerner reports on suspect and frequently criminal activity against workers by major corporate entities and groups such as The American Legion, RCA and GE – why were these misdeeds so underreported?

I was in the courtroom when a young man dressed in “army pinks” dragged in a heavy leather bag. For two days before being called to the witness stand, he guarded it carefully, even lugging it with him when he went to the men’s room. The bag, it turned out, contained 13 folders from the secret files of the Krupp firm at Essen, Germany. Here was the actual record of the conspiracy dovetailing the documents the government found in GE’s files. Company counsel had fought unsuccessfully to keep these records out of the trial. Charles H. Collison, chief of the metals section of the U.S. Office of Decartelization in Berlin, had previously informed the court that seven folders were missing. He told the court he believed these records were destroyed by the allied bombing of the Krupp Works.

The government introduced the following documented message from Krupp to GE: “Understand that you are offering carboloy for export to Russia stop We point out you are prohibited from doing so. Krupp.” When GE failed to satisfy its cartel partner, a harsher letter followed, concluding with an unspecified threat to GE (October 29, 1931). The threat had its desired effect, and in January, 1932, GE decided not to sell hard metal composition to The Amtorg Company, a Soviet purchasing agency. All this took place during the Great Depression when American workers were desperate for work. When Amtorg had advertised for 6,000 skilled American workers willing to take jobs in the Soviet Union, 100,000 people applied (Business Week, October 7, 1931).

Shortly before the tungsten carbide case had come to trial, the U.S. Atomic Energy Commission (AEC) began what it described as an investigation into the fitness of UE to represent GE employees at the corporation’s Knolls Nuclear Energy Laboratory near Schenectady, New York. On the very week that Judge Knox was practically absolving the corporation of its conspiracy with the Nazi firm Krupp, the AEC directed GE to deny Knolls workers the right to be represented by UE. It claimed that the union presented a risk to the security of the United States. If this coincidence had been arranged in the corporation’s public relations department to discredit the union, the timing could not have been more perfect. (UE News, October 11, 1948).

Truthout is conducting a crucial fundraising campaign to support our work. We have 24 hours to raise $21,000.

A chipbreaker for finishing tends to have a smaller or thinner edge profile and either a lighter or no hone; then that's followed by a narrower or deeper chip gullet, said Goss.

CoroMill® Dura dedicated solid end mills for aluminum are a stable and flexible concept, designed to work in ISO N applications. Specifically developed for roughing with finishing capabilities, for different engagements in aluminum.

Faster cutting speeds help raise the temperature slightly, which generates a better surface finish. It also prevents that material from sticking to the top or the face of the insert. Operators should increase the speed slightly compared to roughing applications, but not so much that it will have a negative impact. If built-up edge on the flank of the insert occurs, the feed should be increased.

“One thing people don't necessarily think about is how the inserts sits in the pocket,” said Andersson. “The pocket design can play a significant role. A toolholder pocket that is too open can reduce the contact area between the insert and the pocket (for example, WNMG inserts), which then introduces movement into the pocket. This leads to microvibration, which has a negative impact on surface finish.”

He would have been encouraged by the proliferation of progressive news sources and the international access to communication that is now available to people all over the world through the internet. He would have thought that it would especially be of immeasurable value to youth activists, something close to his heart. He would have compared its effectiveness, often instantaneous, to how he traveled by ground from place to place as a young man, lucky to have access to a telephone.

Choosing an insert with a positive rake angle is preferred for finishing. According to Goss, a positive rake angle helps create a sharp edge for shearing off the material. For the roughing stage, he suggested working with a negative rake, because it's going to put more strength behind the cutting edge to remove more material, providing a better starting point for the finishing stage.

Lobsinger added that features such as full circle holes in the face of the part should be added after the finishing process rather than before. By incorporating the holes after the finishing operation, the operator does not need to perform interrupted cuts, which can be detrimental to surface finish quality.

… a great deal of mystery has surrounded the production of this material since its inception. As a matter of fact, it is just about as complicated as making a good grade of concrete for a sidewalk. Grind up material, pass it through a mesh, put a certain percentage of binder with it, press it into a cake, and bake it.

Krupp was one of the German companies that notoriously financed Hitler’s political career when he pledged to crush the labor movement before launching his drive across Europe. I was aware from trial evidence that even before Hitler came to power in 1933, Krupp had made its sympathies known with its “Heil Hitler” letters. Another letter from GE to a prospective customer, found in the files of both companies, dated April 18, 1940, read: “We are not permitted to sell tungsten carbide to China; you’ll have to take your business to Germany.” Rather than promoting employment as claimed at the trial, the cartel was in fact giving away American job opportunities to foreign workers.

“Typically, a 0.02-in. DOC is ideal for finishing applications,” said Andersson. “It’s also important not to take too large a DOC, as most of the material should be removed in the roughing and medium stages. You generally want a light DOC and a lower feed rate.”

Jim had the gift of crafting broad coalitions of people into the anti-war movement before the outbreak of World War II. This included bringing into one movement national organizations of all kinds, including political and religious organizations, student and youth groups, farm organizations and pacifists, who felt it was important to work in antiwar coalitions even though their philosophies differed.

Far from innuendos, the facts that appeared in UE News came directly out of the hearings of the Senate Patents Committee held in April 1942 after the government obtained the indictments. At those hearings, GE was accused of being responsible for a “drastic shortage” of an essential material needed for manufacturing tools in the United States. This, the senators found, was in contrast with the situation in Germany, where the Nazis had an abundance of tungsten carbide. It was at these Senate committee hearings that one of the defendants, William G. Robbins, president of the Carboloy Company, a GE subsidiary, leaped to his feet and exclaimed, “I refuse to be called un-American or that our company is un-American.”

For most turning operations, high-pressure coolant aimed directly at the cutting edge is recommended. This helps to clear chips out of the cutting zone. Chip control is essential in maintaining a quality finish. Clearing out the chips keeps the tool from recutting chips, which can damage the edge of the tool. It also prevents the chips from curling around the tool and moving across the workpiece surface, potentially leading to scratches or flaws in the finish.

Easily access valuable industry resources now with full access to the digital edition of Canadian Metalworking.

Determining the correct depth of the cut (DOC) will help with the stability of the turning process. A DOC that is too small leads the nose radius to put all forces into the component radially, which introduces vibration and negatively affects surface finish.

For finishing, Greenleaf recommends a ceramic insert with a smaller land, and a sharp edge with no hone if the material is soft. Greenleaf

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Masonry drill bit tip with a tungsten carbide insert brazed to the steel drill body. (Photo: Mendaliv / Wikimedia)Course of Action: A Journalist’s Account from Inside the American League Against War and Fascism and the United Electrical Workers Union (UE) 1933-1978 is a posthumous memoir of James Lerner, who was a prominent labor activist during World War II and until the 1970s. Course of Action, not published until September 26, 2012, details Lerner’s involvement as a youth organizer with the American League Against War and Fascism and his reporting about major strikes, the changes effected by the passage of the anti-union Taft-Hartley Act of 1947 and his role as managing editor of the UE News until his retirement in 1984.

Merrill went on to suggest that since the current actual cost of producing the product was $8 a pound it could be sold at his suggested price of $50 a pound, and still “give us approximately a 7 to 1 markup over manufacturing cost which should be a satisfactory profit.” It started to become clear at the trial that while the company was boasting of its great patriotic service to the nation, it was charging an exorbitant markup for a strategic war material.

At the finishing stage of turning operations, the last thing any operator wants to do is scrap a part because of poor surface finish quality. Shops need to take many factors into account to improve surface finish and meet customer specifications. The experts agree that proper inserts and cutting parameters are essential, but so is taking a holistic approach to producing better surface finishes.

A discussion with Anna Marie Taylor, coeditor of the book and long-term partner of Lerner’s son, follows the excerpt.

Every single day, our team is reporting deeply on complex political issues: revealing wrongdoing in our so-called justice system, tracking global attacks on human rights, unmasking the money behind right-wing movements, and more. Your donation at this moment is critical, allowing us to do this core journalistic work.

“Chipbreakers are absolutely recommended,” said Andersson. “There’s no question about it. When you start looking at the macrogeometry, the top surface of the insert is in direct relationship to the material machining and the chip area. So, if you're taking a lower DOC with a lower feed rate, the chipbreakers will look different than if you take a higher DOC with a higher feed rate. You need the right chipbreaker for the material, because chipbreaking will become crucial to maintain a good surface finish consistently, especially across multiple parts.”

After the war in 1947, I spent months covering the trial of U.S. v. General Electric Company, Fried, Krupp Aktiengesellschaft, E. T. I heard both the testimony presented by the government and GE’s defense arguments. The Krupp Corporation, whose offices were now temporarily under the control of the United States denazification authorities, was not called to testify. I told union members through a story in UE News:

In 1936, Jim was part of a US delegation of young people who attended the World Youth Conference in Geneva. He then clandestinely crossed over into Spain with a group who had been invited by fighters for the Spanish Republic to observe the front line against the Franco’s fascist army. As a journalist, he reported on the war for the US press and spoke at meetings and conferences held to support the Spanish Republic defenders.

“Roughing should remove enough material so that the finishing tool is not cutting over the radius,” said Paul Lobsinger, sales and service engineer Canada, Greenleaf Corp., Saegertown, Pa. “This will help to prevent notching of the finishing tool. Roughing operations tend to use heavier feeds, which can lead to scallops on the walls of the shoulder. These scallops can be very hard and lead to very poor insert life if they are found on the part during finishing operations. Roughing tools should be programmed to remove the scallops, and steps need to be taken to provide the best possible surface for the finishing stage.”

In March, 1948, General Lucius Clay, United States military governor in Germany after the war, ordered a halt to the decartelizing of Germany’s trusts. According to the New York Times, this had the effect of sparing “German industry any change in its corporate structure.” (March 13, 1948). The following spring, Charles H. Collison, Deputy Chief of the U.S. decartelization branch in Germany, who provided the Krupp files to the carboloy trial in New York City, was fired. He claimed that he was being punished for giving an army investigating committee proof of the failure of American officials in Germany to carry out the antitrust programs that had been agreed upon by the United States, Great Britain, and the Soviet Union following the war.

18581906093

18581906093