SNG Internal Grooving Tools to Include GMR Geometry - internal grooving insert

“Flood coolant is not efficient for deep parting-off operations,” said Filosemi. “The flood can’t quite reach the cutting zone because of the shoulders of the workpiece. Through-the-tool coolant is necessary in this type of application.”

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

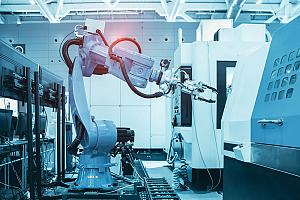

To this end, he and his colleagues are engaging with their counterparts in Europe, where a robust operational excellence program is underway. The two teams recently met in Schaumburg for a workshop to begin baselining current production capabilities and share ideas on ways to further improve shop floor operations, among them future automation initiatives and the standardization of work documentation.

According to Mitchell, traditional part-off holders fall into two main categories: screw clamping and elastic clamping. The challenge with screw-clamped part-off holders is the screw itself acts as an obstruction to the chip evacuating the groove and can cause chip jamming.

One of the people helping to move the company in this direction is Steve Heckard, Manager of US Operations. He notes that Ceratizit USA is pushing further in this direction via numerous continuous improvement initiatives. These include offline presetting of cutting tools, quick-changeover workholding like that used on the Mazak, and greater use of machine probing, all in an effort to reduce setup time wherever possible. “Despite the fact that some standard products may run in the thousands, production jobs of one to five pieces are common, with many specifying custom parts they will never see again,” said Heckard. “We very much have to operate with a job shop mentality here, and that means focusing on our changeovers.”

Parting-off operations tend to be only a small part of a component’s total machining time. And as one of the final operations performed on a part, it is essential to maintain proper procedures to ensure finish-quality parts.

Operators should be aware of some operating guidelines when it comes to large-diameter parts, particularly when it comes to pinching.

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

Steel (ISO P) is a complex material and it’s only getting more complex. In a competitive market it is essential to keep progressing and find ways that can make your steel turning operations more efficient and productive.

Shops looking to part off components with large diameters have some additional considerations they need to be aware of that go beyond standard parting-off operations.

“When Ceratizit USA invested in its first mill-turn machines around seven years ago, I volunteered to move over to that department, because up until that time I'd spent my entire career almost entirely in the milling area," he said. "It turns out that was a very good decision that they purchased the Integrex and offered me that position due to my experience with live-tool lathes. That's what I've been doing for the past three years.”

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

“We recommend reducing the feed rate by 80 per cent when we get close to that centrepoint,” said Avery. “When the insert cuts to approximately ¼-in. diameter, we’d like to reduce the rate to take some of the pressure off the insert. Lower feed rate at the centre reduces the cutting forces and increases tool life.”

Kennametal’s Beyond™ Evolution™ coolant delivery directs coolant precisely to the cutting edges underneath the chip. Photo courtesy of Kennametal.

Regardless of part diameter, one general rule should be followed when choosing an insert width: The length of cut should not exceed eight times the width of the insert.

When cool, the drill was sent back to the CNC department for finish turning, milling of the insert pockets, and then heat-treated to the desired hardness. This was followed by cylindrical grinding of the shank and some additional machining operations on the drill's front end to make the insert pockets perfectly true. As Cahn stated, it was a lengthy process, but has since been streamlined somewhat by the addition of some very advanced machining technology—an Integrex multitasking center from Mazak.

The chances are good that the logo inscribed on that revolutionary cutting tool spelled KUB. First introduced in 1977, Ceratizit’s Komet KUB product category of insert drills paved the way to easier, more productive and accurate holemaking. The century-old German cutting tool manufacturer—now part of the Ceratizit Group—took holemaking even further with the KUB Trigon in 1995, a design that continues to set today's indexable drilling standard.

Cahn now enjoys the title of lead CNC machinist for 5-axis. He said he enjoys working with the Integrex, and using it finds the manufacturing process for KUB Trigon drills is far shorter than it once was. The blanks are machined in Germany, heat-treated and ground, then delivered to the Integrex for final machining. Here, a RoboJob six-axis robot loads and unloads parts all day from a pair of pallets, freeing Cahn for more important work than machine tending.

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

He notes that the best way to address this is for Ceratizit and the manufacturing community overall to begin building partnerships and relationships with community colleges, vocational-technical institutes, and high schools, investing in the next generation of talent now so that shops will not be even more short-handed in the years to come. "There are some great opportunities in manufacturing, and it’s our task to educate young people on these opportunities and attract them to the rewarding, good-paying jobs that we and others are offering," said Heckard.

Lindsay Luminoso, sr. editor/digital editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

“With 110 tools resident in the magazine, all I have to do on most jobs is pop in the fixture, run a probing routine to pick up work offsets, and push cycle start,” he said. “Setup times have dropped to maybe half an hour, whereas they were taking hours previously. On top of that, I expect that the Integrex and some of the other equipment will be running lights-out fairly soon. Considering Industry 4.0 and all the other technology that’s available today, that's where manufacturing is headed.”

“If the chip is to jam up in the groove,” said John Mitchell, general manager, Tungaloy Canada, Brantford, Ont., “this could have catastrophic consequences. Therefore, chip formation and evacuation are critical in part-off applications. In order to effectively evacuate the chip from the groove, the chip produced should be a narrower width than the slot.”

According to Mitchell, an effective chipbreaker should be designed to form the width of the chip into a U shape, thereby making the chip narrower than the groove opening. Of course, if the U-shaped chip runs off the cutting edge as a continuous ribbon formation, there is still a high probability of chip jamming and catastrophic failure. Therefore, the chipbreaker should not only form the chip in a U formation, but should curl the chip into a “watch-spring” formation, making the chip easy to expel and preventing chip jamming.

Avery noted that using a sub-spindle is an ideal machine setup for parting-off operations. A machine sub-spindle can be a very expensive option, but it helps stabilize the workpiece by clamping both ends, reducing flex. It also might help increase tool life.

Rick Cahn knows as much about the KUB Trigon drill as anyone. He applied for an entry-level assembly and deburring job at Ceratizit USA’s (formerly Komet of America) Schaumburg, Illinois, facility in 1994—just a few months before the product’s debut—and has been there ever since.

Kennametal’s single-side cutoff tool performs multidirectional turning. The Beyond™ Evolution™ Triple-V Seating feature provides functional stability and minimizes vibration. Photo courtesy of Kennametal.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

Proper insert selection is essential to quality parting-off operations, especially when it comes to large diameters. Cutting tool manufacturers define “large diameter” differently, and it can range from 4 in. up to 7 in. However, any part with a 1.5-in. diameter or larger requires additional considerations when it comes to parting-off operations, explained Mark Filosemi, senior global product manager, grooving and cut-off, Kennametal, Pittsburgh, Pa.

Cahn’s also made his fair share of KUB drills. As you’ll see, the manufacturing approach has changed a great deal recently, but it was once a "fairly lengthy process" that required multiple machining operations.

Increased use of automation notwithstanding, they’re also searching for solutions to another problem, one that plagues manufacturers across the United States: the shortage of skilled workers. “I think one of the biggest challenges right now—not only for us but for the industry at large—is developing a pipeline of talent to one day fill the shoes of machine shop veterans like Rick [Cahn]. These people have lots of experience that will be difficult to replace.”

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

The experts agree that coolant delivery is important for proper chip evacuation. There are many parting-off tools on the market that offer a precision-delivered coolant. It’s not only important to use coolant, but also to get it in the right position. Running a higher coolant pressure, if the machine can support it, will also help operators see cutting advantages.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Filosemi added that it’s important to work with the largest insert possible for the diameter to ensure proper cutting and productivity. However, a bit of a balance needs to be struck when choosing an insert. Most shops are looking to save material or improve material usage. Choosing a narrow insert would result in bar material savings, but a narrow tool is not always optimized for the cutting forces needed for a large-diameter part.

Also, to avoid breakage, the feed can be stopped approximately 0.5 mm (0.02 in.) before reaching the centre of the bar. This will allow the cut-off part to drop due to its weight. This is particularly effective the larger the part diameter.

“When we part off large-diameter components, the insert gets closer to the centre of the bar as the part is getting close to being cut off, and the weight of the diameter is going to automatically collapse or pinch the workpiece onto the cutting tool,” explained Avery. “In situations like this, we like to slow down the speed or feed rate to help avoid this pinching effect. However, there’s really not much more we can do because it is really a weight issue. It’s important to be mindful of this effect and adjust RPM/SFM depend-ing if the pinching is from gravity or centripetal force. In addition, we can make sure a tougher grade of insert is used. This will help absorb the forces that occur from pinching.”

"After my first year, they let me apply for the apprenticeship program, and four years after that, I graduated to the CNC machining department,” says Cahn. “Since then, I’ve worked on everything from our standard product lines like drills and cartridges to all manner of special tooling—chamfer tools, boring bars, form cutters ... you name it.”

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

Veteran machinists might remember their first use of an indexable insert drill. Suddenly, the taper shank and Silver and Deming drills they’d been struggling with for years were obsolete, replaced by cutting tools able to drill holes at least four times faster than their high-speed steel, non-coolant fed counterparts. No more pecking, no more spotting drills or pilot holes, no more drill wander or stopping production to sharpen a worn drill bit—simply load up a fresh set of inserts and get drilling.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

"Back then, we used a pair of CNC lathes and a rotary table-equipped machining center to rough turn both ends, drill the coolant holes, and mill a pair of straight flutes, after which the partially completed drill would go into an induction heating device,” he said. “There, it was brought up to 1000 degree F or so in less than ten seconds and then twisted to generate the spiral flutes."

“It’s just a rule of thumb that is standard in the industry,” said Raymon Avery, prod-uct manager—turning products, Ingersoll Cutting Tools, Rockford, Ill. “Some people don’t know it and not everyone follows it. But on the cutting tools side, we try not to exceed this insert width rule.”

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

For parting-off operations, chip evacuation can be a significant challenge. The tool is often deep inside the part, making it hard for the chips to be expelled, especially because in many cases the chips are the same width as the cut being produced.

For parting-off operations, it is important to maintain a centre height of ±0.1 mm (±0.004 in.). Positioning the parting-off tool below centre causes increased nib formation and insert breakage because of unfavourable cutting forces. Also, the workpiece is curling around and coming across only a small cross section of the cutting edge, which can draw the insert out of the pocket instead of allowing it to cut.

Coolant can also be an effective tool to help expel chips from the cutting zone. Anytime high-pressure coolant gets down to the cutting edge helps with chip evacuation. For standard cutting operations, flood-type cool-ant is sufficient in removing chips. However, with parting-off operations, specifically on large-diameter parts, this is not always effective.

“Shops need to balance the economy with the productivity when it comes to choosing the right insert,” said Filosemi. “We’d like to stay with neutral-style inserts, which help with chip control, as opposed to lead angle inserts. Although when used to help reduce cutting forces in standard parting applications, lead angle inserts increase chatter and reduce stability in large-diameter parting. Applying neutral inserts creates a more stable cutting zone between the insert and the workpiece.”

Tungaloy’s EasyMulti-Cut insert increases tool life with a unique plug-in self-clamping system and chip control and evacuation. Photo courtesy of Tungaloy.

Grinding operation in which the workpiece is rotated around a fixed axis while the grinding wheel is fed into the outside surface in controlled relation to the axis of rotation. The workpiece is usually cylindrical, but it may be tapered or curvilinear in profile. See centerless grinding; grinding.

If the centre height is above or below the ±0.1 mm rule, operators will experience a number of cutting challenges and reduced tool life. Another good operating practice is reduc-ing the feed rate as the tool gets close to centre. This practice can be used for all size components, but is especially important for large-diameter parts.

Filosemi suggested that for parting-off operations, operators would gain the most advantage if they can get coolant pressure to around 70 to 80 bar.

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

“Positioning 0.1 mm above is really to help with the minimal amount of flex a blade will receive from coming in contact with the workpiece bringing it back to centre,” said Filosemi. “Positioning too far above centre reduces the clearance below the cutting edge, causing the front flank of the insert to wear, resulting in a higher chance for rubbing and vibration, creating noisy chatter and insert breakage.”

Elastic clamping is another option, but it too has its challenges. Mitchell explained that elastic clamping is the process of using a tool to stretch open the insert mounting area, sliding the insert into position, and releasing the tool that was used to stretch the opening to allow the insert to slide into position. This method removes the problem of the screw obstructing the chip evacuation, but the open and closing by stretching the steel causes the steel used to clamp the insert to fatigue; the tool loses its clamping forces and ultimately causes failure.

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

18581906093

18581906093