solid carbide tapered drill-reamer - #20 (.1610) - solid carbide tapered drill bits

The comfort of your body jewelry should be high on your priority list, but your health should certainly be at the top. Using internally threaded jewellery with initial piercings greatly increases your chance of healing quickly and issue free. Internally threaded jewellery does cost a little more, but that is because it is more difficult to manufacture. It is more often made from greater quality materials and truly: when it really comes down to it, can you put a price on your health?

Having internally threaded or press-fit jewellery inserted in a fresh piercing is much more comfortable due to the smooth surface compared to the ridged surface of externally threaded pieces. But this is not the only benefit: bacteria can live inside the teeny threading crevices which wrap around the ends of external jewellery. Which in turn come in direct contact with the piercing. New piercings are susceptible to irritation and infection which can cause a whole range of problems and using externally threaded jewellery unfortunately vastly increases that risk.

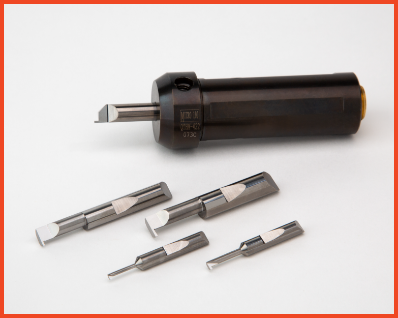

Micro 100 tooling is engineered using the latest CNC grinding technology and manufacturing practices to create the industry’s highest quality products.

Designed in our world class grinding facility in Meridian, Idaho, Micro 100's Micro-Quik product line is a breakthrough system that saves machinists countless hours without sacrificing performance.

Micro 100 has built, and earned, an international reputation for manufacturing high quality solid carbide turning tools that are built to last.

Micro 100 tooling is designed to excel at vastly increased speed and feed rates while providing exceptional results in a wide array of difficult-to-machine materials.

Micro 100 single ended Corner Rounding End Mills feature 1° max flares that are tangent at its pilot and shoulder to avoid st . . .

Add products to your Micro100.com shopping cart and then submit the cart to a participating distributor to place your order

Designed to mill a corner radii onto a part, Micro 100's solid carbide Corner Rounding End Mills are offered in 3 Flute - Single Ended, and 3 Flute - Double Ended styles, each offered fully stocked uncoated or with AlTiN coating.

If you don’t already know that internally threaded or press-fit jewellery is the best choice for your initial piercing you’ve possibly had your head buried in the sand or been on a long holiday to the moon. Big organizations like the Association of Professional Piercers [APP] and companies like Anatometal Inc shout about it all the time because they take great pride in the quality of the body jewellery they promote and produce.

Micro 100 double-ended Corner Rounding End Mills feature 1° max flares that are tangent at its pilot and shoulder to avoid st . . .

Micro 100 tooling is engineered using the latest CNC grinding technology and manufacturing practices to create the industry’s highest quality products.

Designed in our world class grinding facility in Meridian, Idaho, Micro 100's Micro-Quik product line is a breakthrough system that saves machinists countless hours without sacrificing performance.

Add products to your Micro100.com shopping cart and then submit the cart to a participating distributor to place your order

The design of Micro 100's PSC Holders combines a Capto® compatible connection with our proprietary Micro-Quik quick change system, which maximizes productivity by allowing for incredibly fast tool changes.

Micro 100 tooling is designed to excel at vastly increased speed and feed rates while providing exceptional results in a wide array of difficult-to-machine materials.

The design of Micro 100's PSC Holders combines a Capto® compatible connection with our proprietary Micro-Quik quick change system, which maximizes productivity by allowing for incredibly fast tool changes.

Micro 100 has built, and earned, an international reputation for manufacturing high quality solid carbide turning tools that are built to last.

18581906093

18581906093