Speeds and Feeds - aluminum milling speed chart

Yes, our contract manufacturer identification services are designed to assist businesses in navigating the complex landscape of contract manufacturing. We start by defining the ideal contract manufacturer through in-depth discussions with our clients, followed by extensive research to identify potential candidates.

Additionally, IMARC Group's feasibility studies address regulatory procedures, financial assistance, and necessary certifications, ensuring all legal and compliance requirements are met. By covering these aspects, IMARC Group's feasibility studies support informed decision-making, risk reduction, and the overall viability of your business.

The report also covers a detailed analysis of the project economics for setting up a drill bits set manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a drill bits set manufacturing plant.

I both love and hate the camera on the xTool P2. The positive side of it is the smarts: It uses AI to locate the edges of your material to better help you align your designs. This means you can use the offcuts of other projects, put them in the machine and let the camera orientate your designs to best fit in that space, saving you from a lot of wasted materials. Unfortunately, the downside to the camera often makes this hit or miss.

IMARC Group can effectively manage the construction of your new facility through our comprehensive construction management services. Our dedicated construction management team oversees the entire construction phase, ensuring that all activities are executed according to plan and within the specified timeline. We manage contractors, coordinating their efforts to ensure smooth and efficient workflow on-site.

Once potential manufacturers are identified, we conduct a rigorous evaluation and vetting process to ensure they meet high standards of quality, reliability, and compliance with relevant regulations. Our team handles the pre-screening process, arranging meetings between our clients and interested candidates, and managing all logistics to facilitate productive discussions.

IMARC Group's partner identification services help businesses find the ideal distributor, machinery supplier, raw material provider, or contract manufacturer, enhancing operational efficiency and growth.

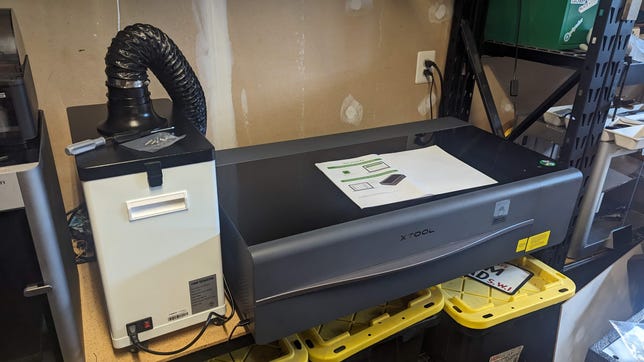

Pro Tip: The laser uses CO2, which requires cooling, so part of the initial setup is filling a reservoir with antifreeze and water. Use distilled water, not tap water. The impurities in tap water will damage the machine over time.

IMARC Group’s report, titled “Drill Bits Set Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a drill bits set manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The drill bits set project report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

The lead generation strategies we use target high-quality quality leads that convert into loyal clients, while our brand promotion strategies including influencer marketing and creative designing enhance the visibility and credibility of your brand. Our social media management services assist you in engaging with your audience, establishing relationships with them, and driving conversions through targeted campaigns.

By partnering with IMARC Group, you benefit from our approach that is tailored to your business needs and unique objectives. Our strategies cover all aspects of digital marketing so that you can reach your target audience consistently, along with our ongoing support and optimization to keep your campaigns effective and relevant. Our cutting edge and performance driven marketing services help you gain the competitive advantage and ensure long-term success.

While we have aimed to create an all-encompassing drill bits set plant project report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include:

Furthermore, our team pays great attention to the progress of the construction work, and we conduct site reviews and quality control to ensure that the construction work is done to the highest standards. We resolve any problems as they arise, thus avoiding any form of delay and keeping the project on schedule. When you work with us, you can be assured that your new facility will be constructed to the highest standards that will enable you to concentrate on your core business activities.

Once the physical setup is complete, you'll need to connect the P2 to your computer. Unfortunately, this has to be done physically the first time, by plugging it directly into a PC or laptop. This was an issue for me as my maker PC is in my office, but if you have a large workspace with a PC already, you should be fine. After the initial setup, the P2 is happy to work over a wired, or wireless connection, which is great, as there is no direct interface on the machine itself.

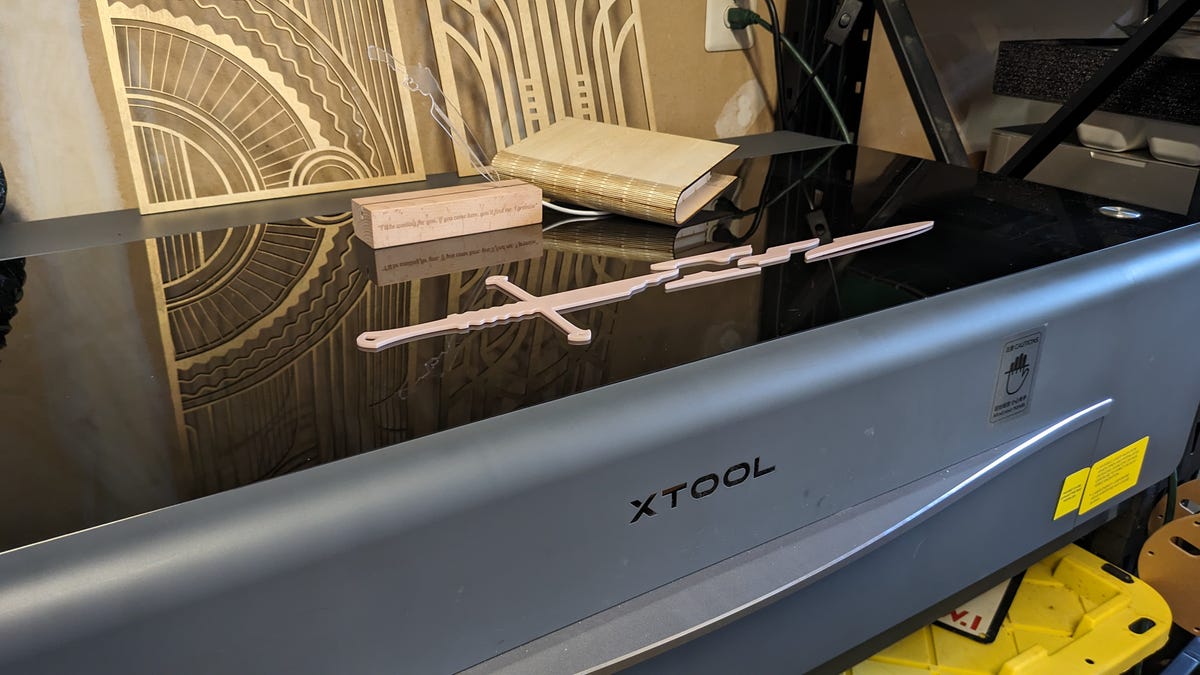

Working in different materials is easy. I made this LED by cutting an image of Squall's Gunblade from clear acrylic and then etching the quote on an LED stand from Amazon. The stand was too thick for the normal cutting platform, but the xTool has a setting that allows you to remove the slats in the base making it deeper, allowing you to cut and etch thicker materials. There is a laser level that helps set the cutting laser to the right height, so you always get the right amount of burn. Mixing materials to create projects is what makes a powerful laser like this stand out from the crowd.

Our holistic approach delivers actionable insights through detailed audit reports, offering clear recommendations for continuous improvement. By partnering with us, you gain valuable insights into your plant's operations, enabling you to drive enhancements, achieve operational excellence, and maintain a competitive edge.

Our process begins with a careful analysis of your particular needs and business goals. We then carry out rigorous research and due diligence to identify the distributors that have market reach and the capability to manage your product lines effectively. Our thorough vetting process involves the distributors' background checks and performance history reviews to ensure that they meet industry standards and have a proven track record.

Be warned: You need a huge amount of room for the conveyor belt, and cutting something all the way through could cause jams. It's best to leave a small tab to hold it in place that can be trimmed off once the cutting is done. I didn't use the conveyor much in my testing -- my workshop isn't set up for passthrough cutting -- but if you build your workspace to accommodate it, I can see the conveyor reducing labor time immensely.

A drill bit set is a collection of tools designed for drilling holes into various materials. They typically include a range of drill bits in different sizes and shapes, each tailored for specific applications. Drill bits are commonly used in construction, woodworking, metalworking, and various do-it-yourself (DIY) projects. They are essential tools in any toolbox, offering versatility and precision in hole creation.

IMARC Group's regulatory approval and licensing services ensure businesses meet all compliance requirements, facilitating smooth and timely market entry.

Our skilled engineering staff specializes in designing efficient and effective plant layouts that meet your unique needs. We begin with a comprehensive process design to ensure the best possible workflow and use of resources.

Another excellent time and material saver is the software. It allows you to use almost any image file, though DXF and SVG are always best, to etch or cut. It offers several ways to take an image and cut it out to remove backgrounds, making the cuts and etches far cleaner. This is great if you've drawn something on paper and need to convert it to a digital file. You can take a picture, and use the xTool software to convert it to a usable file. The software also has a fledgling AI image generator that will generate images from text prompts. So even if you don't have the artwork you want to use, you can have xTool generate it for you. It also has a QR code generator, which is helpful if you want to add business details to your designs.

The global drill bits set market is influenced by a multitude of factors, such as the rapidly expanding construction industry, which has fueled the demand for drill bits as they are essential tools for various applications, such as drilling holes for foundations and fasteners. In line with this, the expansion of the renewable energy sector, particularly wind and solar energy projects, drives the need for specialized drill bits for installation purposes, further favoring the market growth. Additionally, the expanding product application in the oil and gas industry for exploration and extraction activities is another growth-inducing factor. Apart from this, the automotive sector's continuous development contributes to the demand for drill bits in manufacturing and repair processes, which is fueling the market growth. This is further bolstered by the burgeoning do-it-yourself (DIY) culture among consumers. Moreover, rapid urbanization and infrastructure development and technological advancements, such as the introduction of diamond-coated drill bits, are boosting the market growth. Other factors, such as the escalating product use in the aerospace and defense sectors in manufacturing and maintenance applications and the rise of e-commerce platforms, are fostering market expansion.

IMARC Group offers a comprehensive suite of marketing and sales services dedicated to helping businesses increase revenues and effectively sell products. Our performance marketing services focus on data-driven campaigns that maximize return on investment, utilizing programmatic advertising and retargeting techniques to reach the right audience at the right time. We enhance your online presence through SEO and SMO, driving organic traffic and improving your digital footprint.

The P2 has other large-scale tricks up its sleeve too. With an additional conveyor belt system, the P2 can effectively cut an infinite length, limited by the heat of the laser and how well it can keep cool. So it could be used to either cut or etch something very long like a sign or lots of small cuts for mass production.

Yes, our raw material and machinery sourcing services are designed to identify and connect you with reliable and affordable providers. We leverage our extensive network and industry expertise to source high-quality raw materials and advanced machinery that meet your specific requirements.

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, expenditure, and other drill bits set manufacturing plant costs. Additionally, the report provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

IMARC Group's plant audit services offer comprehensive evaluations of your industrial facility's health, efficiency, and regulatory compliance.

We also conduct supplier audits and evaluations so that you get the best value for your investment. We evaluate potential suppliers on the basis of cost, quality, reliability, and delivery timelines. We also make sure that all the legal requirements are met, including customs, tax regulations, labor laws, and import/export laws, to ensure you are fully compliant.

Every job I threw at the P2, from simple etching on glass to a multitude of complex cuts and scores on acrylic, was handled with speed and accuracy. My colleague is currently testing a smaller laser cutter, with a low-powered laser and the difference is remarkable. We both cut the same wooden book, using the same cutting file, and the same images on the front and back. While the P2 managed the entire cut in 21 minutes, his took a whopping 207 minutes (3 hours and 27 minutes). This is why CO2 lasers are used commercially. Completing a job 10 times faster than a cheap laser means you can get more product out of your doors.

When it comes to materials, there's very little that the P2 can't cut -- or at the very least, etch. It can cut 20mm thick clear acrylic, something that's notoriously tough for lasers to cut, as well as just about all woods at 20mm thick. Most of your materials are probably only going to be 3mm or 6mm, but having the option to cut thicker pieces lets you score thick wood deeply. I tried it out on wood, cardboard, two different types of acrylic, brass, anodized aluminum, glass and even a pumpkin pie, and the P2 handled everything with near-perfect precision. I especially liked how well it was able to etch the glass lid from one of my 3D printers with the CNET Logo. It gave the printer a far more premium look.

The lack of display on the P2 is somewhat confusing. All it really has is a temperature gauge and a big "push to go" button. I wish it had more of a display so I could do repeat cuts, or check the progress with more precision but the software does a fairly good job of that. One omission of the software that I find odd, however, is that it doesn't tell you how long your project will take to cut. You can't gauge if you have time for that project or if you need to do something smaller. It's a pain I didn't think would matter to me, but if you're using the P2 for your business, time matters.

Our expert, award-winning staff selects the products we cover and rigorously researches and tests our top picks. If you buy through our links, we may get a commission. Reviews ethics statement

More and more of us are looking to make our hobbies into a side hustle. The best 3D printers let you make things you can sell on Etsy, or at local craft fairs and they're an easy return on investment. The P2 from xTool is the natural progression for someone moving from a hobbyist to something more substantial. Yes, it's $4,500 for the base model, or nearly $6,000 for all the bells and whistles, and for a hobbyist that's a significant chunk of change. If you're a business though -- and one that's growing well and has fresh ideas -- that's a solid investment that will lead to greater profits in the long run.

Lasers are fun and exciting and can make amazing things. Small artistic businesses should invest in the P2 from xTool to make everything faster.

When you choose to work with us, you gain access to a list of suppliers pre-screened for affordability and reliability, helping you optimize your procurement process and reduce overall operational costs. It is our goal to assist you in establishing a new plant effectively and economically, ensuring long-term success and sustainability.

Yes, our regulatory approvals and licensing services are made specifically to support companies in effectively and efficiently navigating the ever-changing regulatory environment. We start by carefully evaluating your company's requirements as well as the unique regulatory framework that applies to your sector. After that, you are assisted by our team of professionals throughout the whole process of securing the necessary industrial permits, business licenses, and environmental clearances.

The report also provides detailed information related to the drill bits set manufacturing process flow and various unit operations involved in a manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

Yes, our distributor identification services are designed to connect companies with trusted distributors who meet high standards of reliability, performance, and ethical practices. We leverage our vast network of vetted distributors across various industries and regions to find the best match for your business needs.

The report provides insights into the landscape of the drill bits set industry at the global level. The report also provides a segment-wise and region-wise breakup of the global drill bits set industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of drill bits set, along with the industry profit margins.

Yes, our site identification services include a thorough assessment of potential sites based on proximity to raw materials, ensuring cost-effective and timely supply chain operations. We also consider access to infrastructure, such as transportation networks, utilities, and technology, which are essential for smooth plant operations. Labor availability is another key factor we analyze to ensure that the site has access to a skilled workforce. Additionally, we evaluate the environmental impact to ensure compliance with regulations and sustainable practices. By integrating these factors, we provide a comprehensive site evaluation to identify the optimal location for your new plant, supporting your strategic goals and operational efficiency.

I write a lot about 3D printing, often called additive manufacturing, but there's also a different way to create called subtractive manufacturing. Laser cutters like the xTool P2 cut away material to create cool art and can be used on a massive variety of materials from wood sheets to the top of your MacBook. The P2 is one of the larger laser cutters I've used, and while it's expensive, it can be a gateway to changing your hobby into your career.

Drill bits are primarily composed of high-speed steel (HSS) or carbide materials. HSS drill bits are popular due to their durability and ability to handle a wide range of materials, including wood, plastic, and mild metals. Carbide bits, on the other hand, are known for their exceptional hardness, making them suitable for drilling through hard materials like concrete, masonry, and ceramics. The uses of a drill bit set are diverse, such as they are instrumental in creating holes for fasteners like screws and bolts, allowing for the assembly of various structures. In woodworking, drill bits are employed to make holes for dowels, enhancing joint strength. Metalworkers use specialized bits for cutting precise holes in metal sheets and pipes. Additionally, drill bits find applications in plumbing, electrical work, and general maintenance tasks. One of the significant advantages of using a drill bit set is the convenience of having a range of bit sizes and types readily available. Moreover, drill bits are designed to offer precision and accuracy, ensuring that holes are drilled with minimal effort and maximum control. Currently, various types of drill bits are available in the market, which include twist, spade, masonry, and countersink bits.

Our audits assess safety protocols to ensure a secure working environment, evaluate quality standards to enhance product satisfaction and optimize processes to increase productivity and reduce costs. Compliance checks ensure adherence to relevant regulations, mitigating legal risks, and our sustainability assessments recommend eco-friendly practices to minimize environmental impact.

IMARC Group's site selection services optimize location choices for businesses, ensuring strategic, cost-effective, and efficient manufacturing operations.

Also, we ensure compliance with the relevant legislation and regulations to avoid legal issues that may affect the functioning of the company. Once potential distributors are identified, we organize business meetings, as well as handle all logistics to facilitate productive discussions. We provide continuous support throughout the partnership, including performance monitoring and logistics coordination, to ensure the success and optimization of your distribution networks in the long run.

Yes, our factory audit services provide a systematic and thorough evaluation of your plant's performance across various critical parameters. Our experienced auditors utilize industry best practices to conduct detailed inspections, focusing on safety, quality, efficiency, compliance, and sustainability.

IMARC Group's factory engineering and design services deliver efficient and customized solutions to enhance operational performance and optimize production processes.

Our feasibility studies assess several key factors to provide a detailed evaluation of your project's potential. The study includes a pricing analysis of feedstocks, helping to understand industry profit margins and cost variations. Detailed insights into mass balance, unit operations, raw material requirements, and the manufacturing process flow are also provided to ensure a clear understanding of the production setup.

The machine is heavy, yet delicate. This is not a one-person lift at all. Make sure you have a team of people to help you put the xTool P2 in place because once it's there, it's there for good. Given that the P2 can be used with a conveyor system, you'll need to make sure there's room at the front and the back if you're thinking of using it that way.

While the xTool boasts two cameras to help you align your materials correctly, those cameras have a fish-eye effect that curls the corners farthest away from them. This makes lining up your design to perfectly fit your material almost impossible. If you're using a 12-by-12 inch piece of wood you can expect to lose around a quarter of an inch on either side to make sure the P2 doesn't cut outside the material area.

(In case you're wondering, the pumpkin pie turned out great. The pumpkin around the cut tastes a little burnt, but it works!)

Our services include careful equipment selection, ensuring that your plant design incorporates the most suitable and advanced machinery. We also focus on meticulous layout planning, strategically arranging workstations and equipment to optimize output and reduce operational bottlenecks. Furthermore, our facility design takes into account every important factor, such as regulatory compliance, scalability, and safety.

The study also covers critical elements such as location analysis, environmental impact, plant layout, and costs associated with land, machinery, raw materials, packaging, transportation, utilities, and human resources. The project economics section provides an in-depth analysis of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity, profitability, payback period, net present value (NPV), uncertainty, and sensitivity analysis.

We have strict performance monitoring and quality control checks to ensure the manufacturers remain at par with your expectations and contribute positively to your business throughout the partnership lifecycle. Through our expertise and extensive network, we ensure that you partner with capable and credible contract manufacturers, who help you drive efficiency, quality, and growth in your production processes.

We use cookies, including third-party, for better services. See our Privacy Policy for more. I ACCEPTX

Additionally, we help with industry-specific regulatory licensing so that your company complies with all sector-specific regulations. To further safeguard your brand and innovations from the outset, we also offer support for intellectual property rights (IPR) registrations and licensing. We manage the required documentation and communicate with pertinent authorities on your behalf by utilizing our deep industry experience and painstaking attention to detail. This allows you to focus on building and growing your business while we take care of the regulatory complexities. Partnering with us ensures that your business is fully compliant and ready to thrive from the start.

By leveraging our expertise, we ensure that your plant layout not only meets your current operational needs but is also adaptable to future growth and technological advancements. Our goal is to create a well-organized, efficient, and compliant facility that enhances your overall operational efficiency and supports your business objectives.

IMARC Group's factory setup services streamline the entire establishment process, ensuring efficient planning, seamless execution, and optimal operational readiness for your manufacturing facility.

When the xTool first arrived, I was taken aback by the weight and quality-feeling parts it had. I've used other laser cutters and few of them have a premium finish like the P2. Simple things make all the difference: There's a pneumatic lid, so it doesn't slam into the machine if you close it, and an LED that turns from blue to green when the door can be opened safely. These touches bring the P2 more in line with the Glowforges of the world, rather than the cheap knockoffs.

18581906093

18581906093