Superhard bulk high-entropy carbides with enhanced toughness via metastable

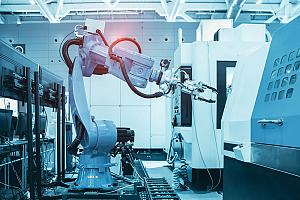

Tungaloy Corp. completed an additional production building at its headquarters in Iwaki, Japan. The new facility is added on to the existing manufacturing complex, which opened in 2011, and will help meet growing demand for cemented carbide inserts, milling tools, and indexable drills, according to the company.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

These inserts have four cutting edges and a clamping design that helps ensure secure insert retention and high repeatability. They are designed for light cutting action as well as good chip control when fed at low feed rates.

Tungaloy has expanded its TetraMini-Cut line of 4-edged grooving inserts to include TCL18 inserts in 1.75-mm and 2.5-mm thicknesses.

ISCAR is About to Change Metal Cutting…AGAIN. NEW Small 06 Square Inserts to be Mounted on Endmills for High Feed Machining

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

The inserts are available in grade AH7025, a nano-multilayer PVD coating with high aluminum content that provides hardness and adhesion to the grade for better process security during grooving operations.

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

18581906093

18581906093