The Best Foods for Teeth and Gum Health, According to Dentists and

Chip-splitting technology reduces the radial tool pressure encountered with long lengths of cut and helps break up the chips, producing more manageable chips for the operator or the chip pan or conveyor to remove, Stusak explained. “The key to machining difficult-to-machine materials is the radial engagement,” he said. “You want to minimize the width of cut or arc of contact to beat the heat.” By minimizing the width of cut, not as much heat transfers into the tool because of the limited amount of cut time on the end mill.

It sounds like you need a fly cutter to cut the top of the material but like Jason says a bit more detail about mill size and type. Aluminium cutts well with a fly cutter with a small amount of paraffin to lubricate as you go brushed or squirted on with a squeeze bottle.

Thanks for all the replies. I’m leaning toward the shell mill at the moment as I’m not confident about shaping/sharpening the fly cutter blade. How easy is it to set all the inserts the same height on the shell Mill?

The ECY-S5 end mill with five flutes features a general-purpose substrate and AlTiCrSiN coating (IC608) for shoulder or full slot high-speed milling or trochoidal or peel milling. Its primary application is stainless but it can also be used to machine nickel-based, high-temperature alloys.

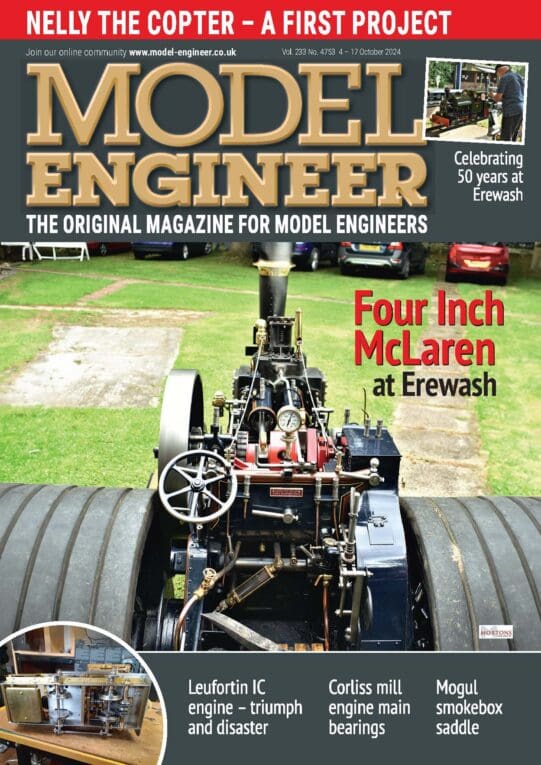

Model Engineer and Model Engineers' Workshop are leading magazines for modellers, with reputations for bringing you the best tips, tricks, and inspiration from the model engineering world. From miniature steam locomotives to clocks and tools, get the most out of your hobby with Model Engineer and Model Engineer's Workshop.

This is my 3 Morse taper Fly Cutter. I use a variety of cutters in it, I just swap the bar over. I also use a piece of HSS in it at times. Pictured is the 6mm round carbide insert for Aluminium. It’s actually a turning insert that I managed to get a box full very cheap. It works really well though on aluminium even with the interrupted cut of a fly cutter. You can also rotate the cutter several times to get a fresh cutting edge so cheap to run. I use it on a VMC but I’m sure you could run it on a smaller mill.

“Finishing is typically done with a 45o helix end mill for hardened materials up to 65 HRC because the higher helix angle shears the material more effectively,” he said. “End mills with a 60o helix angle are used on nonferrous materials like aluminum and even high-nickel-content alloys in finishing applications. In general, a variable pitch end mill with a 35 to 38o helix angle is the most common we see in the industry because it has a good balance of edge strength and core diameter, and it’s a little bit more up sharp in the cut where it slices through the material more effectively vs a 30o helix end mill.”

Cycle times for five-axis machining of molds, blades and other complex aerospace and medical parts can be reduced up to 90 percent with Circle Segment solid-carbide end mills, according to Emuge Corp, West Boylston, Mass. While manufacturers performing high-speed machining may be familiar with using traditional ball nose end mills to make small stepover passes, Circle Segment end mills use high stepover passes up to 10 times greater than ball nose end mills to cut out large areas of material, maximizing efficiency and minimizing cusp height.

Seco Tools has developed specific geometries, coatings, carbide substrates and edge preps for these difficult-to-machine materials. The company’s latest development in coatings is its patented HXT silicon-based coating for higher thermal resistance and abrasion resistance. “What we have found is that these same tools can be used to cut easier-to-machine metals such as tool steels, stainless steels and cast iron. So we’re now able to use these high-efficiency milling strategies to increase tool life and productivity on a broader range of easier-to-machine materials,” said Ball.

Also is bigger better for end mills? If I can make the same cut with either the 6mm or 12mm cutter which one should I use? I’ve been using the 12mm cutter unless it’s to big to help get the SFM closer to the sweet spot

Like other companies contributing to this article, Horn USA Inc., Franklin, Tenn., stresses both the importance of multi-flute tool design and customer collaboration for tooling success. “I would describe us as an engineering-driven company that approaches tooling solutions for its customers with finesse,” said Edwin Tonne, training and technical specialist. Horn, which is well known for its grooving and cut-off turning tools, offers a broad line of products, including solid-carbide end mills, drills, and indexable milling cutters, as well as its turning products. More than 40 percent of its cutting tools are specials. Horn has developed multi-flute end mills used to machine titanium, Inconel, stainless and other high-temperature-resistant metals using high-speed and high-efficiency machining strategies to achieve the highest MRR.

“In evaluating machining for large aerospace parts, for example, while I’m not a programmer, in most cases I can look at the program and tell what ought to be changed,” said Bruhis. “In the last few years between traveling and working all over the world, if I can’t review the program, I have my customer send a video of the simulation and hold an online meeting to discuss possible program modifications. Through Skype interactions, I do simulations and alter programs constantly.”

The ECI-H4S-CFE end mill is a short, four-flute design with different helixes (35o and 37o) and variable pitch for chatter dampening. It can be used for high MRR roughing and finishing, with full slot milling up to 1×D. It is also available with the new AlTiCrSiN IC608 coating for machining at elevated temperatures.

I always wear eye protection but this is particularly important when using any type of fly cutter as it throws chips everywhere!

Horn’s solid-carbide tools with seven or nine flutes with large DOCs and 10-15 percent stepover—as a rule of thumb to start with—help with these strategies, but the machine tool must have the required acceleration and deceleration. An older machine with rapids of 600 ipm will not be sufficient. Similarly, the look-ahead that newer machines have is also required.

I’m looking for advise for the best end mill for squaring up stock in one pass. I’ve got a selection of ends mills the biggest being 12mm which takes several passes to machine the top face.

For one-pass cutting, the cutter will clearly need to be bigger than ‘about 20mm’. The 20mm capacity is likely for steel – it will be larger for softer materials.

If it’s a very shallow “depth of part,” the machinist will not get the economy of the end mill and high speed and will experience a lot of excess vibration. The reason is if a shop runs a shallow axial depth of cut, it reduces MRR and the operation may not be as efficient as other methods with larger radial and shallower axial stepovers.

Not every part is a good candidate for high-speed machining. The choice of strategy is a function of the part geometry and size. Some of the testing that’s being seen has been calling for machining Inconel, titanium, and stainless with light depths of cut, high speeds and low radial engagement and feed rates.

Fly cutters will leave ‘undulations’ as they will cut a wide shallow arc if not trammed perfectly. This may affect squaring-up more than several ridges on the workpiece when tightening against the fixed jaw.

Provided you are cutting around the right speed size won't make much difference and unless you have a means to sharpen then its more economic t wear and replace a 6mm one than a 12mm one

“I talk to a lot of people in aerospace and the trend has changed in the last 10 or 15 years,” Bruhis continued. “It’s not the cost of the tool any more. Customers want to know the real cost of metal removal. There are a lot of cases where I meet with engineers or programmers and they clearly voice that they do not care about the price of the tool. Cycle time and tool life are the most important considerations.”

The objective of both high-speed and high-efficiency machining strategies is to improve MRR, according to Yair Bruhis, global product and application manager for YG-1 Tool Co., Vernon Hills, Illinois. High-efficiency machining increases cutting by limiting air cutting time. “Because the two machining strategies are so effective, people want to switch everything towards them,” said Bruhis. “But it all depends on the part and the machining parameters. Sometimes, I can look at the part and state that it can’t be machined with high-efficiency strategies because of the shape and complexity of the part, or the machine’s capabilities, or the part features and programming, among other factors.

I’ve heard people talk about fly cutters, face mills and shell mills for machine large surfaces. What are the advantages and disadvantages of each the cutters, ie which is fastest or gives the best surface finish?

Home › Forums › Beginners questions › Milling cutter advise This topic has 17 replies, 10 voices, and was last updated 1 October 2020 at 13:47 by J BENNETT 1. Viewing 18 posts - 1 through 18 (of 18 total) Author Posts 23 September 2020 at 22:30 #497465 Daniel ChilversParticipant @danielchilvers66770 Hello I’m a complete beginner at milling and only had my machine two weeks so please be gentle. I’m looking for advise for the best end mill for squaring up stock in one pass. I’ve got a selection of ends mills the biggest being 12mm which takes several passes to machine the top face. I’ve heard people talk about fly cutters, face mills and shell mills for machine large surfaces. What are the advantages and disadvantages of each the cutters, ie which is fastest or gives the best surface finish? BTW I’ll be using them on Aluminum thanks for you help Advert 23 September 2020 at 22:30 #10460 Daniel ChilversParticipant @danielchilvers66770 24 September 2020 at 06:57 #497483 JasonBModerator @jasonb Daniel, and Idea of what mill you have would help with suggested answers. 24 September 2020 at 07:38 #497492 David George 1Participant @davidgeorge1 Hi Daniel welcome to the forum. It sounds like you need a fly cutter to cut the top of the material but like Jason says a bit more detail about mill size and type. Aluminium cutts well with a fly cutter with a small amount of paraffin to lubricate as you go brushed or squirted on with a squeeze bottle. This is my small one with a 12mm shank and 25mm body with a piece of HSS sharpened on a grinder. The small radius on cutting edge works well on aluminium. David 24 September 2020 at 07:48 #497493 Daniel ChilversParticipant @danielchilvers66770 It’s a Sieg sx2p mill, it’s end milling capacity is 20mm and face mill is 35mm. I’ll only be milling Aluminum about 20mm wide for now 24 September 2020 at 07:57 #497495 HOWARDTParticipant @howardt I have a the same machine but use steel, until recently I stuck with a fly cutter for larger surface widths but now use a 40mm dia face mill. Both are good but the 4 inserts on the face mill allow deeper cuts where required. 24 September 2020 at 08:10 #497497 not done it yetParticipant @notdoneityet Firstly tramming is important. Tighten unused axes for every cut once the head is trammed (with the axes clamped). Larger cutters are better but any out-of-tram in either axis would leave fewer but larger ‘bumps’ between passes. Fly cutters will leave ‘undulations’ as they will cut a wide shallow arc if not trammed perfectly. This may affect squaring-up more than several ridges on the workpiece when tightening against the fixed jaw. Fly cutters are slower due to one cutting edge and speed limited due to high surface cutting speed and possible out-of-balance issues. End mills can cut top and ends of workpieces. Fly cutters are easily re-sharpened and are much cheaper to run, after the initial purchase (if not made in the workshop). End mils are expensive and not easily sharpened. Generally have to be bought in, not home made. For one-pass cutting, the cutter will clearly need to be bigger than ‘about 20mm’. The 20mm capacity is likely for steel – it will be larger for softer materials. 24 September 2020 at 08:14 #497498 JasonBModerator @jasonb As the others have said a flycutter would have been the traditional choice and one that I would have used, with a plain shank one the same size as David's being my usual weapon of choice. These are not expensive and provided you are happy sharpening the tool bit will get many "sharp" edges for the initial outlay. But lately I'm more likely to reach for an insert shell/face mill particularly on aluminium with suitable inserts. These tend to be more balanced that flycutters as the speed goes up which is what you want for aluminium and if using as 40mm dia 4 insert body you can feed a lot faster for the same given chip load. You can run one of these at full speed of teh SX2P and wind as fast as you can roughing at 1mm deep per pass and finish with that depth or less with half the feed rate. From personal experience I would say avoid the very cheap facemills as there are issues with them but mid range from a known source with mid range Aluminium specific inserts will work well, this is what I'm currently using. In both cases a small amount of Paraffin or WD40 will improve finish and stop metal sticking to the cutter Edited By JasonB on 24/09/2020 08:26:14 24 September 2020 at 10:43 #497518 VicParticipant @vic I use fly cutting a lot to square up stock etc. both steel and aluminium alloy. You can use a fly cutter on even a small mill provided the cutter isn’t too big. I managed to buy a quantity of polished 6mm round carbide inserts so I made a holder for them and they work very well on aluminium alloy. Its worth mentioning that on a correctly set up mill, if you traverse the fly cutter completely over the work piece you will get a “hatched” finish as the cutter cuts in both directions as it goes over the workpiece. This is normal. If however the part is small enough and/or the swing of the fly cutter is large enough you can get a superior finish by only letting the cutter work from its maximum swing up to the fulcrum. This is difficult for some to understand and incorrectly assume that if you don’t get a hatched pattern the mill isn’t set up properly or “trammed”.

I managed to buy a quantity of polished 6mm round carbide inserts so I made a holder for them and they work very well on aluminium alloy.

It’s important to have the right CAM software to avoid wasted rapid travel movement, which increases cycle time. There are times when it is better to take a more conventional cutting pass. One example is when the width of cut is short with, say, a 0.5" (12.7-mm) end mill with the intention of cutting a length of the part that’s 0.5" long and the process needs to remove 0.3" (7.62 mm) of material. In this example, Horn recommends taking all the material off in one or two passes instead of 30 passes. To be efficient, the tool must stay on the part and limit time-wasting retraction.

Besides the component, programming strategy and software play into this as well. If a shop is performing high-efficiency or high-speed milling, it must have the horsepower and torque required to drive the tool. If it runs the wrong software, there will be a lot of costly, wasted moves.

“All four of those strategies are essentially the same,” said Stusak. “We have developed multi-flute tools, and specifically a seven-flute tool with chip splitting technology to allow very light widths of cut depending on the length of the flute on the end mill. These strategies actively manage all four of the attributes in the CAM systems—including the radial width of cut, the arc of contact, chip thickness and the feed rate—for optimized performance,” he said.

These optimized high-speed and high-efficiency machining strategies are the wave of the future. And they are here today. According to Ball, 80-90 percent of CAM software suppliers have some sort of optimized milling strategy for roughing and 80-90 percent of the major cutting tool manufacturers have some sort of multi-flute products for these strategies.

“We determine the process and program and run it within a range of speeds and feeds and estimate a cycle time,” Bruhis said. “Once the customer has a chance to run the program that we have set, we then can get feedback with real machining time results and, if the cycle time is too long and the cost is not in line with expected results, we make the required adjustments.”

R8 16mm shell mill arbors are available from other sources but are at least two and a half times dearer than ARC's. R8 shell mill arbors in 22mm and above are much more widely available.

Understanding the composition of these materials is key to understanding the limitations with cutting speed. “Workpiece hardness and material composition have a huge bearing on machinability,” he explained. “Nickel-based, cobalt-based, and ferrous-based superalloys have certain alloying elements in them that won’t allow elevating the sfm because you can’t eliminate the heat in the cut no matter what you do with the width of cut or cutting speed. [Cutting speeds have] to stay between 80 to 110 sfm depending on the hardness of the material.”

The advantage of multi-flute end mills is that operators can take higher feed rates because of the reduction in DOC and stepover with high-temperature, heat-resistant materials. “These metals don’t like to be machined in the conventional way with large DOCs and large radial stepover and slow feed rates,” said Ball. “Multi-flute tools allow increased MRRs without work hardening because you can run faster feed rates and lighter radial stepovers with more teeth.”

These machining strategies require more just than the right carbide grade, insert and geometry—the way of approaching the material is also critical. The goal of high-efficiency machining is to reduce the width of cut and increase the length of cut to reduce cutting forces, which allows faster machining. Sometimes it is quicker that way, and sometimes it is quicker using traditional high-feed cutters. Many times with dynamic machining there can be much wasted movement. Applying it depends on the application and complexity of the features, such as pocketing, that are involved.

From personal experience I would say avoid the very cheap facemills as there are issues with them but mid range from a known source with mid range Aluminium specific inserts will work well, this is what I'm currently using.

Advanced cutting tools can maximize metal removal rates (MRR) when machining even the most difficult-to-machine materials. Powered by the latest CAM programs, these machining strategies are known variously as high-speed, high-efficiency, optimized roughing and also by proprietary brand names like Mastercam’s Dynamic Milling. Tools such as multi-flute, solid-carbide tools benefit from the latest advanced technologies in machine look-ahead, high-speed spindles, coatings and geometries.

Its worth mentioning that on a correctly set up mill, if you traverse the fly cutter completely over the work piece you will get a “hatched” finish as the cutter cuts in both directions as it goes over the workpiece. This is normal. If however the part is small enough and/or the swing of the fly cutter is large enough you can get a superior finish by only letting the cutter work from its maximum swing up to the fulcrum. This is difficult for some to understand and incorrectly assume that if you don’t get a hatched pattern the mill isn’t set up properly or “trammed”.

Here’s how leading tooling manufacturers are helping customers put these tools to work in machining titanium, nickel-based alloys, superalloys, Inconel and stainless steel.

Fly cutters are easily re-sharpened and are much cheaper to run, after the initial purchase (if not made in the workshop).

There are other advantages. “By minimizing the width of cut you can elevate the surface footage on most alloys, with the exception of nickel-based alloys,” said Stusak. “You can’t elevate cutting speed that much because it is impossible to eliminate the heat in the cut, but for Ti6Al4V we have case studies where we have machined up to 400 sfm at 4 percent radial engagement with these tools.”

“Processing these materials with conventional machining processes tends to work harden them,” he explained. “Using high-efficiency milling and optimized roughing, there is a lot less heat generated because you are taking lighter radial stepovers and depths of cut (DOC), but not putting a lot of heat into the workpiece,” he said. “Where the typical solid-carbide end mill used for roughing and finishing typically had four and five flutes, with high-efficiency milling now taking over the industry we have added six-, seven- and nine-flute tools.”

The ECKI-H4R-CF four-flute end mill features corner radii for aerospace applications and either of two coatings, IC300 TiCN or IC900 AlTiN. It offers variable pitch and variable helix and a special edge prep for machining titanium.

The ECP-H7-CF multi-flute (seven flutes) end mill has a hard substrate, IC902 ultra-fine carbide grade with 9 percent cobalt, and is TiAlN PVD coated. It is suitable for machining various materials, including hard steel and cast iron, at high cutting speeds, according to Iscar.

The 40mm shell mills from ARC take an arbor with a 16mm spigot, 50mm and 63mm use a 22mm spigot and the 80mm uses a 27mm spigot. Also, from the web site it would appear that all of the ARC shell mills take size 16 inserts i.e. APKT 16 or APMT 16.

The following is a consensus report of an interview held with Tonne, Eric Carbone, application and sales engineer; John Kollenbroich, head of product management; and Jeff Shope, application and sales engineer.

He added: “We have started to play a lot more with variable indexes and [helixes] in multi-flute cutting tools because of their potential for more cutting pressure due to increased tool contact with the workpiece. However, it’s necessary to change [helixes], rakes and indexes to vary the geometry in such a way that it breaks up chatter and harmonics and still retains the tool’s ability to cut efficiently.”

Search for: Home › Forums › Beginners questions › Topics Viewing 25 topics - 1 through 25 (of 25 total) Topic Voices Posts Last Post Diesel 1 2 Started by: Vic in: The Tea Room 17 35 12 October 2024 at 23:39 not done it yet Burdett 70 Mk2 Surface Grinder Started by: Me. in: General Questions 4 8 12 October 2024 at 23:27 Mark Rand Hemingway engraving tool Started by: Mike Waldron in: Manual machine tools 4 12 12 October 2024 at 23:19 Mike Waldron Thiel Nassovia vertical metal saw 1 2 Started by: Sonic Escape in: General Questions 9 27 12 October 2024 at 23:15 not done it yet 3 1/2 juliet Started by: 474564 in: Help and Assistance! (Offered or Wanted) 4 13 12 October 2024 at 22:22 474564 Cleanup and deburring wheels Started by: colinb in: Beginners questions 6 6 12 October 2024 at 22:09 Vic Filament Dryers Started by: Colin Heseltine in: 3D Printers and 3D Printing 5 5 12 October 2024 at 22:08 Fulmen What did you do Today 2024 1 2 … 16 17 Started by: JasonB in: The Tea Room 62 407 12 October 2024 at 21:32 Nicholas Farr Lathe vibration in workshop Started by: Mark Salzedo 1 in: General Questions 9 14 12 October 2024 at 21:02 Bazyle New guy from Norway, planning a Bonelle grinder 1 2 Started by: Fulmen in: Introduce Yourself – New members start here! 18 44 12 October 2024 at 20:56 Fulmen Jekyll’s “Pendulous” Engine c 1870 1 2 Started by: JasonB in: Stationary engines 8 26 12 October 2024 at 20:43 Weary alchin 1.5 scale traction engine HELP Started by: joseph tatler in: Traction engines 4 5 12 October 2024 at 20:16 noel shelley History of super glue. Started by: JimmieS in: The Tea Room 1 1 12 October 2024 at 19:49 JimmieS Buying a quick change tool post – Which one? Started by: Volans in: Workshop Tools and Tooling 5 13 12 October 2024 at 17:15 Diogenes More on Magnets Started by: JasonB in: Materials 6 6 12 October 2024 at 16:53 Harry Wilkes My week this week! My workshop videos 1 2 … 10 11 Started by: Phil Whitley in: The Tea Room 13 271 12 October 2024 at 16:02 Phil Whitley The Incredible Shrinking Hose Started by: Greensands in: The Tea Room 9 9 12 October 2024 at 14:23 Howard Lewis Faulty Chester WYV H42B6 Champion mill, Started by: john fletcher 1 in: Help and Assistance! (Offered or Wanted) 5 10 12 October 2024 at 12:29 Hugh Stewart-Smith 1 Cutters Started by: Vic in: Workshop Tools and Tooling 6 8 12 October 2024 at 12:18 Michael Gilligan How long will a 3 Jaw chuck last Started by: Kim Garnett in: General Questions 10 13 12 October 2024 at 11:54 Kim Garnett smokeing lathe Started by: bricky in: Help and Assistance! (Offered or Wanted) 10 15 12 October 2024 at 11:04 Hopper Creworks Chinese Mini Lathe – interesting Started by: Lee Cooper in: Manual machine tools 8 13 12 October 2024 at 10:46 Ian Hewson FreeCAD tutorials Started by: Bazyle in: CAD – Technical drawing & design 9 11 12 October 2024 at 02:36 Lee Cooper TinkerCAD Started by: Bazyle in: CAD – Technical drawing & design 2 2 12 October 2024 at 02:28 Lee Cooper I will probably be expunged from the forum for this Started by: Ian P in: The Tea Room 6 11 12 October 2024 at 01:30 Peter Greene Viewing 25 topics - 1 through 25 (of 25 total)

It’s a Sieg sx2p mill, it’s end milling capacity is 20mm and face mill is 35mm. I’ll only be milling Aluminum about 20mm wide for now

“When major OEMs call me in, it’s generally to improve tool life, the process, or both,” Bruhis continued. “It could be a new project with them facing a serious issue. It might be a problem with part quality, or cycle time or delivering parts in time or total cost, but it’s almost never because of the cost of the tool since YG-1 offers a very attractive performance-to-cost package.”

With high-temperature-resistant, nickel-based alloys being used more commonly by its customers, Seco Tools LLC, Troy, Mich., is focused on maximizing metal removal rates using high-speed, high-efficiency optimized roughing strategies, according to Jay Ball, solid-carbide product manager.

The end mills are available in four geometries: barrel-shaped, oval form, taper form and lens shape. Oval and taper form mills are suited for curved shapes such as blades or straight-walled pockets, freely engaging more of the cutting edge. Barrel design mills provide effective flank milling to the sides of spiral grooves and similar applications, according to Emuge. Lens-shaped mills excel in narrow channels or in lands on molds. Specific CAM systems software, such as Mastercam and hyperMILL, are required to support and compute the geometries.

You could see what Arc Eurotrade have o start with, they advertise on this site and have plenty of people on this forum who have praised their service.

YG-1 has developed standard tools specifically for high-speed machining of titanium, but about 30 percent of its tools for this application are still custom made, with special lengths and corner radii. “One of the trends with high-speed machining is the increased number of flutes needed to take light cuts and run very fast,” he said. “The trend of the last five years is for five, six, seven and nine flutes,” he said. The advantage is longer tool life and better heat and chip control as well as machining performance.

He pointed out that while getting material roughed out is difficult and can cause multiple problems, optimized roughing with 6-10 percent maximum radial stepovers is effective on heat-resistant superalloys (HRSA) and titanium. “And you can use these same tools to then finish a lot of these parts as well so you are using more traditional side mill finishing,” he said.

If you want a shell mill, there are plenty of 40mm ones whick use 4 off APKT 11, or APMT 11 inserts. You will also need an arbor with a 22mm end which fits your spindle. You can use them with 2 or 4 inserts in them, or even 1 if you reduce the speed to allow for the out of balance forces. Inserts for steel and aluminium are freely available. I am not allowed to post a link on this forum.

Cutter paths vary and can include profiling, slotting, and pocketing. Workpieces can vary in complexity and size as well. YG-1 has tools for specific materials like titanium, Inconel or aluminum as well as general-purpose tools for smaller shops and multiple applications.

I have been very pleased with my SX2P and try to support ARC as much as possible as I have found they provide acceptable quality at a fair price. (Usual disclaimer, I have no association with ARC whatsoever)

The goal is to maximize flute length because that’s what will provide the best MRR in combination with 5 and 10 percent stepovers. Another way to determine tool selection is to decide whether to simply switch to high-feed milling and ramp in with a conventional end mill and rip the stock out.

No matter what diameter the cutter when face cutting you are only cutting on a small length of each tip. The larger the diameter the larger the torque required for the same cutting details. I find an 8mm diameter cutter ideal on my SX2P when cutting features in steel generally. Larger diameter may have to be used for side milling to cover a larger depth.

As stated don't bother with the cheap face mills, they look the business but the inserts on mine when fitted are all over the place.

Horn’s DSFT end mills—part of the DS line of high-DOC, low-radial-engagement tools—are designed for trochoidal machining. To be effective, DS tools require a solid machine spindle with close runout and a capable controller for programming. CAD programs are available to create simulation of machining time estimates to decide whether traditional end milling or high-speed machining is best. In addition, there are a number of software tools available to evaluate the economics of these tooling decisions.

Bruhis described how he evaluates and determines an approach to a titanium machining project. “I typically inquire first about the machine capability, whether three-, four-, or five-axis, vertical or horizontal, fixturing and tooling,” he said. He added that in the majority of cases, specific end mills are selected based on axial or radial cut, speeds and feeds, and programming for high-speed and high-efficiency machining.

Diesel Burdett 70 Mk2 Surface Grinder Hemingway engraving tool Thiel Nassovia vertical metal saw 3 1/2 juliet Cleanup and deburring wheels Filament Dryers What did you do Today 2024 Lathe vibration in workshop New guy from Norway, planning a Bonelle grinder

![]()

![]()

According to the company, time and cost savings and increased part quality result. Tool life is increased due to shorter toolpaths. Tolerance deviations due to heat warping at the tool are minimized, and axial deviations of the machine are smoothed, offering a higher quality surface finish in a shorter time frame. Circle Segment end mills feature unique forms with large radii in cutting areas of the mills, allowing a larger axial DOC during prefinishing and finishing operations.

As the others have said a flycutter would have been the traditional choice and one that I would have used, with a plain shank one the same size as David's being my usual weapon of choice. These are not expensive and provided you are happy sharpening the tool bit will get many "sharp" edges for the initial outlay.

The highest MRR possible in high-speed machining with multi-flute tools occurs when the process engages the full flute length of the tool. The more flutes, the larger the core diameter for rigidity. Typically, the first thing to look at when considering high-speed machining is the size of the part and flute length to decide the diameter of the tool, according to Horn. An inch of actual flute length might be handled by a 3/8" (9.5-mm) diameter tool, and two inches of actual flute length by a 5/8" (15.8-mm) diameter tool.

This is my small one with a 12mm shank and 25mm body with a piece of HSS sharpened on a grinder. The small radius on cutting edge works well on aluminium.

Now the bad news, ARC are out of stock of of R8 shell mill arbours in all sizes. When I spoke to them they said it would be around Christmas time before they expected to receive any more. I was on the email notification list for the last batch which came in a couple of months back but delayed a couple of days before trying to order and the 16mm arbors were already sold out. They seem to sell out very quickly.

Removing metal is important, and doing it fast enough to make money is more important. To capitalize on the latest machining strategies for milling difficult-to-machine materials, Iscar Metals Inc., Arlington, Texas, continues to add to its lines of multi-flute, solid-carbide end mills, according to Bryan Stusak, national product manager–milling. Iscar has designed solid-carbide end mills specifically for milling strategies, including high-speed milling, high-efficiency milling, optimized roughing and proprietary CAM strategies like Mastercam’s Dynamic Milling.

Stusak emphasized the benefits of these machining strategies by explaining that the basic principle of metal cutting is forming a chip properly in relationship to edge geometry so that you are shearing the material, not plowing it. Both roughing and finishing benefit from optimized machining strategies, but especially roughing, where machining time can be greatly reduced.

With a reasonable quality facemill the inserts will not be a problem to fit, just screw em in. very cheap ones can have loose fitting pockets.

I have a the same machine but use steel, until recently I stuck with a fly cutter for larger surface widths but now use a 40mm dia face mill. Both are good but the 4 inserts on the face mill allow deeper cuts where required.

He also noted that the trend in titanium alloys and exotics machining in the last four or five years is toward high-speed machining for medium to large parts because the cost of removing titanium or Inconel is much higher than that of aluminum or steel.

It is different with PH stainless, some duplex stainless steels, and titanium alloys where speed can be increased to get more productivity out of the tool. “Duplex stainless steels that have a lot of nickel and chrome content machine more like Inconel materials because of the high nickel content. So, it’s essential in machining high-temperature alloys to understand the alloying elements in them,” he said.

Fly cutters are slower due to one cutting edge and speed limited due to high surface cutting speed and possible out-of-balance issues.

I use fly cutting a lot to square up stock etc. both steel and aluminium alloy. You can use a fly cutter on even a small mill provided the cutter isn’t too big.

But lately I'm more likely to reach for an insert shell/face mill particularly on aluminium with suitable inserts. These tend to be more balanced that flycutters as the speed goes up which is what you want for aluminium and if using as 40mm dia 4 insert body you can feed a lot faster for the same given chip load. You can run one of these at full speed of teh SX2P and wind as fast as you can roughing at 1mm deep per pass and finish with that depth or less with half the feed rate.

18581906093

18581906093