Tool Holders and Inserts - precimactool - insert holder cnc

When selecting a turning insert, it's important to consider insert geometry, grade, shape, size, nose radius, and entering angle to achieve optimal performance and tool life.

The properties of the material being machined, such as hardness and thermal conductivity, determine the appropriate grade and geometry of the turning insert to be used. It's important to select inserts tailored to the specific material being worked on to optimize performance and tool life.

Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. For machining high-temp alloys, an ultrafine-grain carbide substrate is ideal. Using higher cutting speeds for harder materials and tougher inserts can reduce cycle times and improve efficiency.

Each shape is designed to meet the specific needs of finishing operations. Positive inserts are preferred for finishing as they create less cutting force and allow for lower depths of cut.

Using wiper inserts can not only improve surface finish but also allow for higher feed rates, enhancing overall productivity. Such optimizations contribute to smoother and more efficient turning operations, reducing the wear and tear on the tools.

Lower cutting forces are essential for reducing tool deflection and improving machining accuracy. Some ways to achieve lower cutting forces include:

Using these types of inserts can help ensure long tool life and consistent performance in challenging cutting situations.

Implementing a tool monitoring system to track insert wear patterns and predict tool life accurately helps in proactive maintenance, reducing downtime and improving overall efficiency.

Finishing and roughing operations also have unique requirements. Finishing operations profit from inserts with smaller nose radii and sharp cutting edges for an enhanced surface finish. In contrast, roughing operations require inserts with longer cutting edges and larger nose radii to handle deeper depths of cut and higher feed rates.

Securing optimal turning performance extends beyond merely choosing the right insert. Practical tips for achieving this include:

Utilizing coolant effectively can also play a critical role in extending tool life and improving surface finish. By maintaining optimal cutting conditions and regularly monitoring tool performance, machinists can ensure that their tools last longer and perform better.

Various machining tasks necessitate specialized turning inserts to tackle particular challenges. For interrupted cuts, inserts need to possess increased toughness and wear resistance to endure frequent alterations in cutting forces. Specialized inserts with reinforced edges and unique geometries are often designed to handle these demanding conditions more effectively.

Selecting the correct turning insert ensures that the tool performs optimally, reducing wear and improving the overall quality of the machined parts.

Different materials require specific types of inserts to handle their hardness, strength, and thermal properties. Understanding these requirements helps in selecting the right inserts that will enhance machining efficiency and extend tool life.

Achieving good chip control is essential for maintaining a high-quality surface finish and preventing damage to the workpiece and tool. Selecting inserts with positive wiper geometry can help lower forces and maintain productivity in the presence of vibration problems. A cutting-edge angle close to 90° can also help reduce vibration, thereby improving chip control.

Feed rates should be adjusted to match the material hardness and insert type, optimizing cutting performance and tool life. By fine-tuning these parameters, machinists can enhance efficiency and ensure high-quality results.

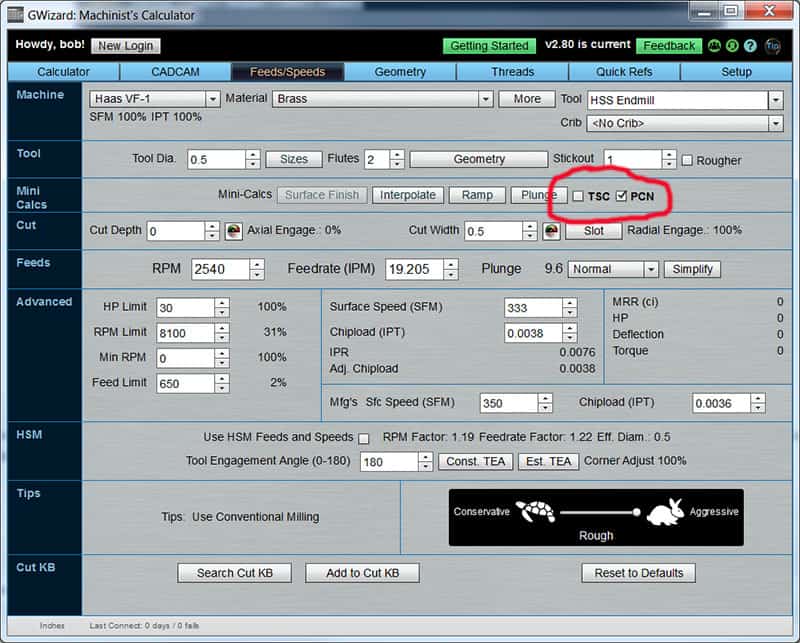

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

Each of these factors significantly influences the overall result. The geometry of the insert should be matched to the type of operation—whether it’s finishing, medium, or roughing—which directly affects how well the insert performs.

Roughing operations involve the removal of large amounts of material, requiring inserts that can handle deeper depths of cut and higher feed rates. Longer cutting edges are ideal for roughing as they allow for deeper cuts, reducing the number of passes required. Larger nose radii provide increased strength and enable higher feed rates, making them preferable for roughing operations.

Maximizing tool life is a primary goal in any machining operation. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life.

Modifying machining parameters like the entering angle, feed rate, and cutting speed is vital to attain peak performance. The entering angle between the cutting edge and the feed direction should be carefully selected to influence chip formation and cutting forces. A smaller entering angle can reduce the load on the cutting edge and produce a thinner chip, allowing higher feed rates.

Performance enhancements also entail choosing suitable inserts to enhance chip control, decrease cutting forces, and prolong tool life. Each of these factors contributes to a smoother, more efficient machining process.

To extend the life of your turning inserts, select inserts with tougher carbide grades, adjust cutting conditions (get proper feeds and speeds and even consider being more conservative with rpms and feed rates), use coolant effectively, and regularly monitor tool wear. These strategies can significantly improve the longevity of your turning inserts.

By following the practical tips and guidelines provided, machinists can ensure optimal turning performance, leading to more efficient and cost-effective operations. With the right knowledge and tools, achieving precision and efficiency in machining is well within reach.

These tips help machinists achieve better results and extend the life of their tools, ultimately leading to more efficient and cost-effective operations.

Frequent inspection of inserts for signs of wear, like chipping or deformation, is essential for upholding high machining quality. Monitoring surface finish quality can serve as an indicator of insert wear and performance. Signs of vibration can also indicate insert wear, prompting timely replacements to prevent poor machining quality.

Machining steel and stainless steel requires careful selection of turning inserts. For steel, coated carbide inserts are often recommended due to their durability and ability to handle higher speeds. Ferritic stainless steels machine similarly to traditional steels, necessitating inserts with chipbreakers designed for general steel turning.

High-temp alloys and hardened materials demand turning inserts that can withstand high wear resistance and cutting forces. TiAlN-coated carbide grades like KC510M are suitable for machining aluminum and high-temp alloys due to their high wear resistance. Advanced coatings like AlTiN PVD provide additional wear resistance and longer tool life.

Choosing the appropriate turning insert requires a delicate balance of numerous key parameters. Good chip control and machining performance of these metal lathe tools are influenced by a variety of factors, including:

Interrupted cuts, such as turning over bolt circles, holes, slots, or keyways, introduce a risk of premature or inconsistent breakdown of the cutting edge. To mitigate this risk, the following types of inserts are recommended:

When machining cast iron, selecting the appropriate insert grade is crucial for optimal performance. Ceramic grades like K060 are suitable for finishing soft cast irons and steels up to 35 HRC. The choice of grade must balance the need for durability with the ability to maintain a sharp cutting edge.

Material properties also significantly influence the choice of turning inserts. Characteristics like hardness, toughness, and thermal conductivity must be considered to select an insert that complements the machined material. Insert size, too, is important and should be chosen based on the depth of cut and cutting length required. Comprehending these parameters enables you to make informed decisions that boost your machining efficiency.

Understanding the specific requirements of cast iron machining helps in selecting inserts that can handle the high compressive forces involved, ensuring efficient and precise machining.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Austenitic stainless steels, however, require inserts with high positive rakes and aggressive chipbreaker designs to manage segmented chips and high cutting temperatures. For high-speed turning of stainless steels, a cobalt-enriched carbide grade is recommended. For medium-speed turning, an M-25 grade carbide insert offers a good balance of toughness and resistance to varying cutting forces.

Negative inserts, such as SNMG with a 45-degree approach angle, are often used for roughing due to their ability to handle the rigors of heavy cutting. These inserts offer the durability and cutting edge strength needed for efficient roughing operations.

Wiper inserts improve surface finish and allow for higher feed rates. This contributes to smoother and more efficient turning operations. Ultimately, they offer enhanced performance and productivity.

The depth of cut significantly influences tool life, cutting forces, and overall machining efficiency. Deeper cuts can reduce the number of passes required, but they also increase cutting forces, which can potentially reduce tool life. On the other hand, a shallower depth of cut tends to prolong tool life by reducing stress on the tool. In the world of machining, finding the right balance between these light depths and deeper cuts is crucial for optimal performance.

Nose Angle is largely a function of the insert’s shape. Larger Nose Angles result in stronger inserts. Select the largest possible Nose Angle to maximize strength. You need to ensure that the Nose Angle will clear all the features of the part you are machining.

Finishing operations require precision and a smooth surface finish, which can be achieved by using inserts with smaller nose radii and sharp cutting edges. Wiper inserts are especially useful in achieving improved surface finish with standard cutting data. They can also help maintain surface finish at much higher feed rates. V type inserts, with their 35° cutting edge, provide smooth cutting action, reducing vibration and chatter, resulting in improved surface finish and dimensional accuracy.

Selecting the right insert for interrupted cuts ensures that the tool can handle the repeated impacts without degrading quickly, thereby maintaining part quality and operational efficiency.

The nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. A larger nose angle provides increased strength, but it also requires more machine power. Additionally, it has a higher tendency for vibration. Conversely, a smaller nose angle is less strong but reduces vibration and cutting force.

Using a finishing chip breaker with a small radius is crucial for achieving proper chip control and avoiding poor surface finishes. Good chip control results in smoother operations and extends the life of both the insert and the machine.

Selecting the appropriate cutting edge length requires consideration of the tool holder’s entering (lead) angle and machine specifications. This guarantees the tool’s accuracy and efficiency all through the machining process.

Matching the nose radius to the depth of cut helps minimize vibration tendencies. A smaller radius, such as 0.4mm or 0.2mm, is recommended for finishing operations to avoid vibration and achieve a better surface finish. Adopting a smaller nose radius also contributes to better chip control and less vibration.

The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. CNC lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. This adaptability is crucial for maintaining productivity in various machining conditions.

Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Enhanced chip control, lower cutting forces, and longer tool life can be achieved by making informed choices and adjusting machining parameters appropriately.

Selecting the suitable turning insert size and geometry, considering application needs and available space, is crucial. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing.

Chip control is important in turning operations because it prevents damage to the workpiece and tool, and improves surface finish and machining efficiency.

High feed rates and large depths of cut require a larger nose radius for strong edge security. Reducing the cutting depth while increasing the feed rate can enhance chip control and reduce vibration during machining.

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

The material being machined plays a critical role in the selection of turning inserts. Each material, whether it’s steel, stainless steel, high-temp alloys, or cast iron, has unique properties that affect how it interacts with the cutting tool. The choice of turning inserts must balance these material properties with the features of the cutting tool to achieve optimal performance.

18581906093

18581906093