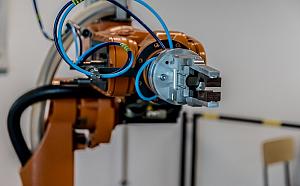

Defect Inspection of Indexable Inserts with Machine Vision and AI - indexable insert in cnc tooling

A differential pitch provides optimum operational smoothness and extends tool life, the company states.

Easily access valuable industry resources now with full access to the digital edition of Canadian Metalworking.

Easily access valuable industry resources now with full access to the digital edition of Canadian Metalworking.

The Turbo 10 cutter bodies that hold the PCD05 and PCD20 include precision milled pocket seats that improve run-out, stability and tool life by providing optimal contact between the tool body and insert. Integrated through-coolant channels support high productivity and promote excellent chip evacuation. Because of their high levels of flexibility, Turbo 10 cutters work in slotting, shouldering, ramping, facing, pocketing, plunging and turn milling applications.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

The micro-geometry of the tool makes the cutter suitable for finishing high-wall part features. The tool also has a 35-degree helix and a DIN 6535 HA (round cylindrical) shank. The uncoated WJ30UU-grade cutter is available in diameters from 12 mm to 20 mm.

Featuring solid carbide insert bodies, the PCD05 and PCD20 come in the company’s X010 insert size with a corner radius of .016" (0.4 mm) and wiper length of 0.43" (1.08 mm).

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

ISCAR's New Products 2024 NEW Head with 3 Effective Cutting Edges for Boring and Enlarging Hole Sizes

The cutting tool was specifically designed for finishing and dynamic roughing of deep pockets and cavities. Dynamic milling involves machining at a low radial depth of cut (ae), a high axial depth of cut (ap), and with a large cutting edge length (Lc), which is three times the cutting edge diameter (Dc) on these tools.

The DC160 from Walter is the next generation of drilling • High productivity in many different materials • Can be used universally in an extremely wide range of applications • Lands positioned very far forward to ensure fast guidance in the hole • Remarkable positioning accuracy thanks to the innovative new thinner web

PCD05 and PCD20 milling insert grades work alone or alongside carbide inserts in the same Turbo 10 cutter body. When used with carbide inserts, the PCD insert grades serve as wiper inserts in fixed pockets. Conversely, running the PCD05 and PCD20 in one Turbo 10 cutter body optimizes their potential and ensures maximum cutting parameters.

Walter has unveiled the MC166 Advance solid-carbide milling cutter, which is suitable for all industrial sectors that machine aluminum, copper, brass, bronze, and magnesium-based alloys (ISO N workpiece group).

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

Perfect for aerospace and automotive part production, these well-proven grades produce excellent surface quality in finish machining applications involving aluminum and titanium alloy workpiece materials. These PCD grades are also highly effective in cutting polymers and fiber-reinforced composites.

18581906093

18581906093