Understanding the ISO Code System for Turning Inserts - grooving insert nomenclature

CC6220 and CC6230 excel in demanding materials in intermediate stage machining. They take productivity to a new level compared to whisker ceramics and SiAIONs both when it comes to cutting speed and feed. Both grades are specifically developed for turbine discs in HRSA material, such as Inconel 718 and powder metallurgical nickel-based alloys.

The Sandvik Coromant grade assortment for HRSAs includes CVD and PVD coated carbide grades, ceramic and cubic boric nitride (CBN) grades for various machining conditions. Use the information below to find the right grade for your production requirements.

Challenging machining places high demands on insert grades for turning heat resistant super alloys (HRSAs) and titanium.

Carbide grades should have good edge toughness and good adhesion of the coating to the substrate to provide good resistance to plastic deformation. In general, use inserts with a large entering angle (round inserts) and select a positive insert geometry. In turning and milling, ceramic grades can be used, depending on the application.

CC670: Whisker-reinforced, alumina-based ceramic with excellent bulk toughness designed for turning and grooving. View assortment of CC670.

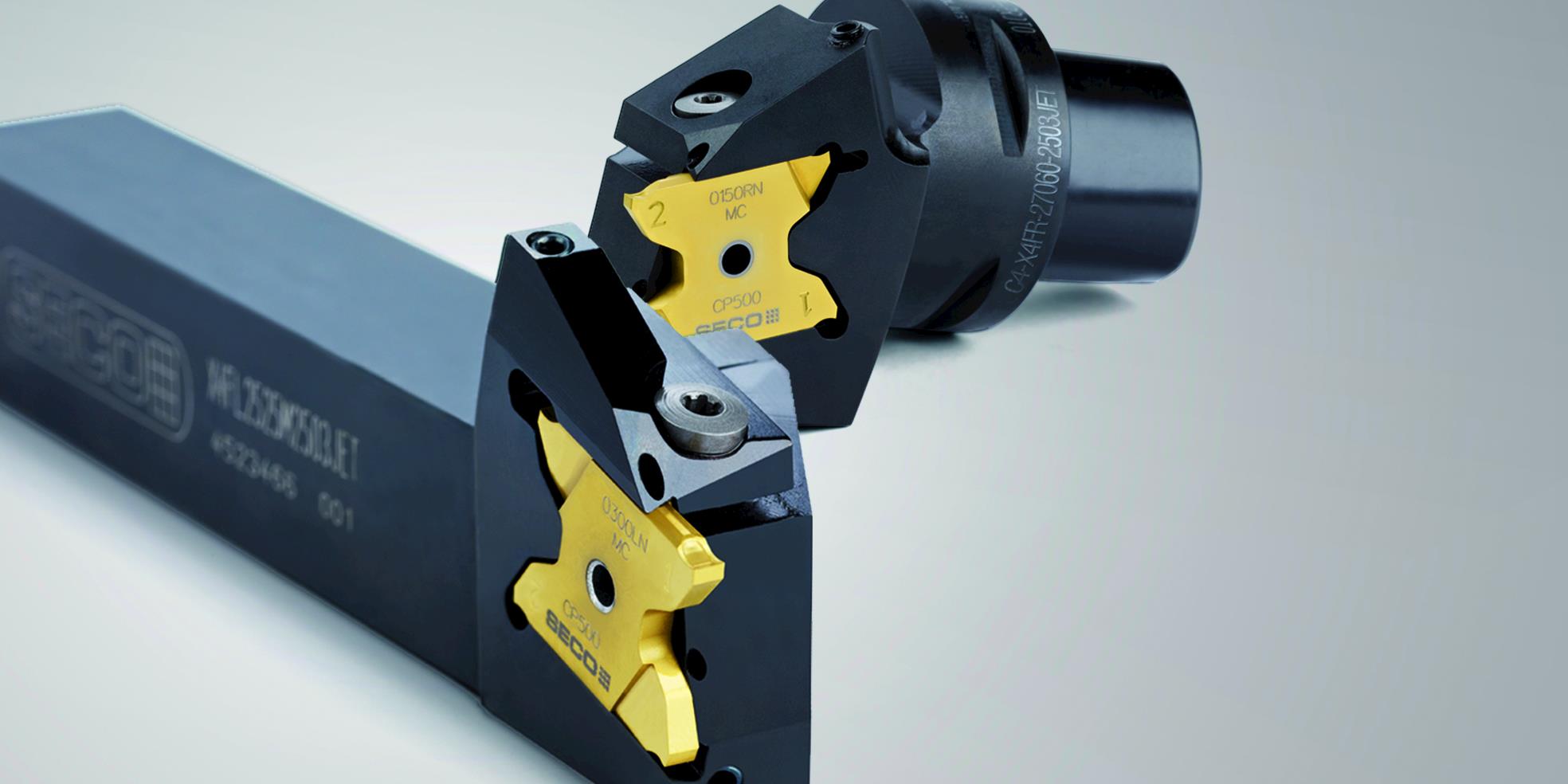

The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert.

It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system.

Sandvik Coromant is the world’s leading supplier of tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development they create unique innovations and set new productivity standards together with their customers. These include the world's major automotive, aerospace and energy industries.

Signing into Better MRO is easy. Use your MSCdirect.com username / password, or register to create an account. We’ll bring you back here as soon as you’re done.

GC1115: PVD-coated carbide grade with high hardness and good resistance against plastic deformation combined with good edge-line security. View assortment of GC1115.

CC6160: SiAION based ceramic designed to optimize performance in nickel-based materials under relatively stable conditions and offer high security and predictable wear as a result of high notch resistance. View assortment of CC6160.

CC6060: SiAION based ceramic for optimized performance in pre-machined materials under stable conditions. View assortment of CC6060.

CC6065: SiAION based ceramic that offers good toughness and security in toughness-demanding operations. View assortment of CC6065.

President of Haimer USA Brendt Holden demonstrates how setting up your complete tool assemblies the same way every time can increase productivity and, in turn, save you time and money.

The new ceramic grades CC6220 and CC6230 are developed to machine demanding materials where whisker ceramic and SiAIONs fall short. Their ability to handle high cutting speeds contributes to reduced cost per component.

THE ISO designation system for indexable insertsThe ISO designation system for indexable inserts (ISO 1832) is a standardized system to name an indexable insert.The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert. This system has several advantages:Unique naming of an indexable insert (supplier independent)All important features and dimensions are clearly stated in the nameSome code positions relate to the insert carrier in which the insert can be mounted It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system. This is an example for milling inserts. For other applications, you can refer to the relevant Machining Navigator. Do you want to know more?Contact Us Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

There is a growing demand for aerospace engine parts that can withstand extreme temperatures, beyond the capability of Inconel and other high performing super alloys. While powder metallurgic materials can be tailored to handle substantially higher temperatures, they are more difficult to machine than Inconel 718.

Poor heat conductivity and high hardness generate high temperatures during machining. The high strength, work hardening and adhesion hardening properties create notch wear at maximum depth of cut and an extremely abrasive environment for the cutting edge.

Challenging machining places high demands on insert grades for turning heat resistant super alloys (HRSAs) and titanium. Machinability of HRSA-materials increases in difficulty according to the following sequence: iron based materials, nickel based materials and cobalt based materials. All the materials have high strength at high temperatures and produce segmented chips during cutting which create high and dynamic cutting forces.

To learn more about the different grades available for your HRSA turning operations, see below a short description and link to the products.

18581906093

18581906093