Vardex FF6751973 3ILG60 Grade VTX - Threading Insert - vardex threading insert grades

Looking again at the inserts (eg here https://www.shop-apt.co.uk/metric-iso-external-threading-inserts/16er-175-iso-t300-external-threading-insert.html – usual no connection, they are quick and reasonably priced). They have what looks like a 'parallel' cutting edge, would I be right in assuming that it will start cutting the OD if I try to cut beyond the thread depth?

![]()

One gotcha with partial profiles is that they need a bit of extra infeed over book values for all except the smallest pitch. Due to the point dimensions being set for the smallest thread they are a little more pointed, and so longer, than book size for the other threads in the range.

Best inserts found that cut well and last longer than all others are Iscar and Seco. Do have cheapies from various places and they don't last in comparison by as much as 4 times.

Those inserts designed for a specific thread pitch will correctly form both the root and crest for the particular thread pitch.

If your doing threading that don't require or can get away without the proper form and tolerance, choose a universal angle as mentioned above which purely cut a V. These will come either 55 or 60 degree designated by angle after the ER or IR number ie IR16 internal or ER16 then A55 A60 etc. Unless Sandvik that use special coding irrelevant to to what all the rest abide by.

Full form will be to the specific pitch ie ER16 1.25 which will be external 1.25mm pitch with correct radius for the root.

Note that external and internal threading inserts for the same nominal thread are different, to account for the differences in internal and external thread forms. As in this picture of external and internal full profile inserts for the same thread form, in this case 2mm pitch ISO:

I screwcut a lot of imperial, mainly Whitworth form threads, and I prefer to use the pitch specific inserts as they give the correct root and crest radii.

I would 'imagine' that the rounding at the very tip of the tool would increase in size relative to the pitch desired to be cut.

Home › Forums › General Questions › Threading inserts – why different sizes? This topic has 9 replies, 8 voices, and was last updated 21 November 2016 at 20:09 by Jon. Viewing 10 posts - 1 through 10 (of 10 total) Author Posts 20 November 2016 at 12:13 #267511 simon Hewitt 1Participant @simonhewitt1 Why do indexable thread inserts come in different pitch sizes? Surely the geometry is always the same? Its just the thread depth? Or is it a question of strength? If I only want to buy one or two, to cut from say M4 to M12, what should I get? Advert 20 November 2016 at 12:13 #24886 simon Hewitt 1Participant @simonhewitt1 20 November 2016 at 12:18 #267513 simon Hewitt 1Participant @simonhewitt1 Looking again at the inserts (eg here https://www.shop-apt.co.uk/metric-iso-external-threading-inserts/16er-175-iso-t300-external-threading-insert.html – usual no connection, they are quick and reasonably priced). They have what looks like a 'parallel' cutting edge, would I be right in assuming that it will start cutting the OD if I try to cut beyond the thread depth? Which suggests a coarser pitch insert will cut finer threads no problem?

One of the many reasons I like the Zero-2-Zero threading method is that its a lot easier to sort out what's going on and make corrections for such things.

You want a "partial profile" insert (aka "agnostic" by the Mercans). This has the 60 degree angle but doesn't have the rounded tip which is particular to a specific thread pitch. You should be able to make do with 1 or 2 such inserts to cover the range you need.

*This is a Berkshire eSupply item* Please note, Berkshire has many challenges with delivery dates, discontinued items, etc. Unfortunately, this is beyond our control and we cannot be held responsible for such. Any and all cancelled orders due to circumstances beyond Freers control will be subject to a 4% cancellation fee that will not be waived. By checking out, you agree to these terms.

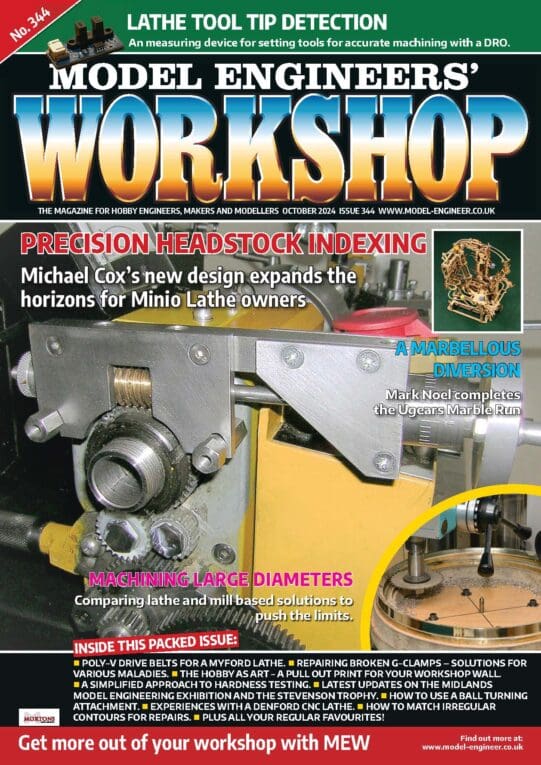

Model Engineer and Model Engineers' Workshop are leading magazines for modellers, with reputations for bringing you the best tips, tricks, and inspiration from the model engineering world. From miniature steam locomotives to clocks and tools, get the most out of your hobby with Model Engineer and Model Engineer's Workshop.

Freer Tool & Supply 44675 Morley Drive Clinton Township, MI 48036 586-463-3200 Sales@freertool.com

![]()

Chinese Mini-Lathes/Mills – DC Motor Controllers Stuart Dynamo Hot rolled angle problems Willis Farmers Engine in 2″ scale Sizing of 1/4” hex shanks What did you do Today 2024 Lathe headstock bearing access SC2 mini lathe pops RCD when turned on? My very own Quick Change toolpost Thiel Nassovia vertical metal saw

*Product images may differ from actual purchased item.***Please contact Sales@freertool.com for all lead times before placing your order. Once paid for, any cancellations will have a 4% cancellation fee.**

Search for: Home › Forums › General Questions › Topics Viewing 25 topics - 1 through 25 (of 25 total) Topic Voices Posts Last Post Chinese Mini-Lathes/Mills – DC Motor Controllers Started by: Andre ROUSSEAU in: Help and Assistance! (Offered or Wanted) 4 5 10 October 2024 at 08:22 John Haine Stuart Dynamo 1 2 3 Started by: Steve Rowbotham in: Beginners questions 12 59 10 October 2024 at 07:50 JasonB Hot rolled angle problems Started by: Mick Bailey in: Materials 7 20 10 October 2024 at 07:17 JasonB Willis Farmers Engine in 2″ scale Started by: Luker in: Work In Progress and completed items 5 6 10 October 2024 at 07:10 JasonB Sizing of 1/4” hex shanks Started by: Bill Phinn in: Workshop Tools and Tooling 14 22 10 October 2024 at 06:57 JasonB What did you do Today 2024 1 2 … 16 17 Started by: JasonB in: The Tea Room 62 401 9 October 2024 at 22:40 Nigel Graham 2 Lathe headstock bearing access Started by: Mike Hurley in: Manual machine tools 5 7 9 October 2024 at 22:12 Huub SC2 mini lathe pops RCD when turned on? 1 2 Started by: andy198712 in: General Questions 8 28 9 October 2024 at 22:10 SillyOldDuffer My very own Quick Change toolpost 1 2 Started by: Iain Downs in: Workshop Tools and Tooling 15 30 9 October 2024 at 22:07 Huub Thiel Nassovia vertical metal saw Started by: Sonic Escape in: General Questions 8 23 9 October 2024 at 12:18 not done it yet About cheap grinders 1 2 Started by: Sonic Escape in: Workshop Tools and Tooling 18 33 9 October 2024 at 12:03 Tony Pratt 1 Racing Motor Cycle Adhesion 1 2 Started by: Peter Cook 6 in: The Tea Room 18 35 9 October 2024 at 11:27 Hopper Bed for 6040 CNC? 1 2 3 4 Started by: Steve355 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools 12 90 9 October 2024 at 10:20 Steve355 Deleted messages Started by: jimmy b in: New Forum Software questions, comments and Test Threads 1 1 9 October 2024 at 08:49 jimmy b Chester Super Lux advice 1 2 … 5 6 Started by: Taf_Pembs in: Manual machine tools 18 134 9 October 2024 at 05:22 Michael Gilligan Weather Started by: Michael Gilligan in: The Tea Room 1 1 9 October 2024 at 05:11 Michael Gilligan Arnfield Gravity Escapement Started by: Michael Gilligan in: Clocks and Scientific Instruments 6 21 8 October 2024 at 22:29 Michael Gilligan Tich Loco. A sad tale. Can anyone help? 1 2 Started by: simon1479 in: Introduce Yourself – New members start here! 10 29 8 October 2024 at 22:23 duncan webster 1 Making a tool holder for lathe inserts Started by: Steviegtr in: Workshop Tools and Tooling 9 17 8 October 2024 at 17:06 old mart Farm Boy 1 2 3 4 Started by: Dalboy in: I/C Engines 14 85 8 October 2024 at 17:01 Dalboy Adhesive to bond a pair of machined flat surfaces Started by: Craig Brown in: General Questions 13 24 8 October 2024 at 16:59 ega Diesel 1 2 Started by: Vic in: The Tea Room 17 33 8 October 2024 at 15:39 Martin Kyte Regulator lever Started by: Garry Coles in: General Questions 6 6 8 October 2024 at 11:08 duncan webster 1 Midlands Model Engineering Exhibition 17th – 20th October Started by: Meridienne Exhibitions 1 in: Exhibitions, Shows and Club Events 12 21 8 October 2024 at 07:14 Martin Kyte DRO scales 1 2 Started by: Dalboy in: General Questions 13 27 7 October 2024 at 22:24 Pete Viewing 25 topics - 1 through 25 (of 25 total)

Inserts that cover a range of pitches have the correct thread angle, but the root dimensions are set for the finest pitch, and will therefore be incorrect for coarser pitches. In addition they do not form the outer diameter or crest.

Why do indexable thread inserts come in different pitch sizes? Surely the geometry is always the same? Its just the thread depth? Or is it a question of strength? If I only want to buy one or two, to cut from say M4 to M12, what should I get?

Personally do a lot of high tolerance stuff that require every morsel of strength, no play. Full form way to go as each cut takes down the root and o/d. Major reason I like the set to zero and plunge in 90 degrees, no messing about way is you have a direct measurement of depth going in which will change with every pitch and tolerance.

The helix angle will be different for coarser/finer threads and different pitches.. why many inserts claim a limited range of pitches.

"Full Form" inserts have the correct rounding for the crests and valleys so are size specific, "partial form" are not rounded so will cover a range of pitches per insert but you may need to knock the corners off the crests with a fine file

There are two basic types of indexible threading inserts; those specific to one pitch, and those that cover a range of pitches.

18581906093

18581906093