DX110 PCD Insert Grade - carbide insert negative rake

Tianjin Key Laboratory of Materials Laminating Fabrication and Interface control Technology, Hebei University of Technology, Tianjin, 300132, China

Kim, H. C., Shon, I. J. & Munir, Z. A. Rapid sintering of ultra-fine WC-10 wt% Co by high-frequency induction heating. J Mater. Sci. 40, 2849–2854 (2005).

Understandably, many of the new coatings have been developed to increase production in exotic and difficult-to-machine materials, but not all. Some new coatings boost production for established, more common materials.

Uncoated inserts, along with the CVD and PVD coated inserts, benefit from new substrates. For coated inserts, new chemical formulas continue to make them last longer, be more efficient, and have the ability to cut established and new materials faster.

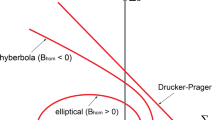

The model for calculating the separation energy of the WC/Co phase boundary and the separation energies for various WC/Co phase boundaries.

Aaron-Michael B. Eller, product manager—ISO turning and advanced materials, Seco Tools LLC, said, “In PVD aluminum titanium nitride or titanium nitride coatings, the atoms are arranged in a cubic form. During use, structural and compositional changes take place. Some are helpful but others are not. By controlling the coating process, we can encourage the good and deter the bad, resulting in increased speed capability and wear resistance.

Juslin, N. et al. Analytical interatomic potential for modeling nonequilibrium processes in the W-C-H system. Journal of applied physics. 98, 123520 (2005).

Iscar’s grade IC6025 structure is for turning ISO M materials. Each layer of the coating and its thickness are chosen to meet a specific need. Photo courtesy of Iscar.

H.X., X.S. and F.Y. performed the simulation and wrote the main manuscript text. H.X. and Y.Z. prepared the figures. All authors reviewed the manuscript. The authors have no competing financial interests.

Sue Roberts, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. A metalworking industry veteran, she has contributed to marketing communications efforts and written B2B articles for the metal forming and fabricating, agriculture, food, financial, and regional tourism industries.

Adorjan, A. et al. WC grain growth during the early stages of sintering, Int. Journal of Refractory Metals and Hard Materials 24, 365–373 (2006).

A top layer of coating such as a colourful chrome that wears away to expose the different colour of the layer below can, by itself, provide a significant increase in productivity.

Coatings like Sumitomo’s CVD Absotech Platinum are designed to increase cutting speeds and improve cuts in carbon steels, tool steels, and stainless steels. Photo courtesy of Sumitomo Electric Carbide Inc.

Lu, K., Lu, L. & Suresh, S. Strengthening Materials by Engineering Coherent Internal Boundaries at the Nanoscale. Science 324, 349–352 (2009).

The WC-Co cemented carbides are widely used in industries owing to their excellent mechanical properties1,2,3. Examples of typical applications of the WC-Co cemented carbides are cutting, machining, mining, drilling tools and wear parts. Hardness and fracture toughness are the two most important mechanical properties of the WC-Co cemented carbides; other mechanical properties, such as impact resistance and wear resistance, are fundamentally dependent on the hardness and fracture toughness. As described by the Hall-Petch relation4,5, the hardness of the WC-Co cemented carbides increases with decreasing grain size. Therefore intensive efforts have been made to study the WC-Co cemented carbides with ultrafine or nanocrystalline grain structures6,7,8,9,10. However, it is well-known that the fracture toughness of the WC-Co cemented carbides is inversely proportional to the grain size; so a finer grain size usually results in lower fracture toughness11,12,13. Naturally, how synthesizing WC-Co cemented carbides with both high hardness and high fracture toughness is still challenging.

Cha, I. S., Hong, S. H. & Kim, B. K. Spark plasma sintering behavior of nanocrystalline WC–10Co cemented carbide powders. Mater Sci Eng A 351, 31–38 (2003).

where A is the area of the WC/Co phase boundary. To construct the incoherent WC/Co phase boundary, we hold the WC part still and rotate the Co part by an angle about Y axes; then calculate the separation energies of the incoherent WC/Co phase boundary using the same method as above. Since the stoichiometric WC (0001) has two different surfaces: one C-terminated and the other W-terminated; therefore there are two different types WC/Co phase boundaries. We name the C-terminated WC/Co phase boundary as C/Co type phase boundary and the W-terminated WC/Co phase boundary as W/Co type phase boundary.

Sumitomo’s CVD Absotech™ Platinum coating is a multilayer aluminum oxide/titanium carbon nitride designed mainly to cut carbon steels, tool steels, and stainless steel. Copher said that the Absotech Bronze PVD coating of titanium aluminum silicon nitride is recommended for interrupted machining of stainless steel and exotic materials.

Xiong, J., Yang, J. G. & Guo, X. H. Application of rare earth elements in cemented carbide inserts, drawing dies and mining tools. Mater. Sci. Eng. A. 209, 287–293 (1996).

Each layer of a nanolaminate PVD coating is approximately 7 nm thick. Varying the individual layer materials and thicknesses makes it possible to adjust the hardness and thermal stability properties. Photo courtesy of Seco Tools LLC.

Figure 1 illustrates stress-strain curves of the two models. As shown, below strain value of 6.6%, the two stress-strain curves are almost completely overlapped and the stress increase with the increasing of the strain, indicating that at the present stage no crack occurs and the deformation mechanism of the two models is insensitive to the joint types of the WC/Co phase boundaries. Moreover, the present stage can be further divided into two sub-stages: below strain value of 2.1%, the stress is directly proportional to strain and the Young’s modulus holds constant. When the strain value is between 2.1% to 6.6%, nonlinear stress-strain behavior can be found and the Young’s modulus decreases with the increasing of strain. The different stress-strain behaviors of the two sub-stages maybe suggest different deformation mechanisms of the two nanocrystalline WC-Co cemented carbide models. Beyond the strain value of 6.6%, the stress will drop, at the same time cracks begin to nucleate at the WC grain boundaries. From the figure it can be found that the stress-strain behavior of the two models is remarkably different: the stress of the coherent model drops more slowly than that of the incoherent model (for instance, at 15% strain the stress of the incoherent model drops to 1.6 GPa, however, the stress of the coherent model only drops to 6.9 GPa). This indicates that the coherent model possesses higher fracture toughness than the incoherent model.

Most of the coatings, nearly 90 per cent according to tooling manufacturers, are multilayer. The elements making up each layer, the thickness of each layer, and the order in which they are applied to the insert dictate what materials they can cut and how long they will last.

Furthermore, the Fig. 1 also displays the relaxation process of the two models. If the two models are relaxed from the highest stress pointes of the two stress–strain curves, the stress linearly decreases with the decreasing of the strain. When the stress decreases to zero, the strain only decreases to 1.49%; this indicates that the two models have conducted a plastic deformation process during the tensile process.

Steve Geisel, senior product manager at Iscar Canada, said that there are three main categories of coatings: chemical vapour deposition (CVD), physical vapour deposition (PVD), and uncoated. CVD coatings are generally thicker and allow machining at higher surface footage, which can be good for machining carbon and alloy steels. PVD coatings are for the high-temperature alloy materials because the coatings are very thin to allow the insert to absorb heat. That quality avoids work hardening that would be caused by heat reflecting back into the cut or chip. Uncoated inserts are used for high temperature applications like titanium because many of the coatings have a titanium layer and the cutting tool needs to be harder than the material being cut.

Nosé, S. A. Unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 81, 511–519 (1984).

Sherif, E. M. et al. Synthesis and characterizations of ball-milled nanocrystalline WC and nanocomposite WC-Co powders and subsequent consolidations. J. Alloy Compd. 312, 315–325 (2000).

Song, X. Y. et al. Effect of interfacial characteristics on toughness of nanocrystalline cemented carbides. Acta Mater. 61, 2154–2162 (2013).

Richter, V. & Ruthendorf, M. On hardness and toughness of ultrafine and nanocrystalline hard materials. Int J Refract Metals Hard Mater 17, 141–152 (1999).

Tooling manufacturers continually experiment with new mixes of standard coating materials and introduce new elements.

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

As we know, separation energy is usually used to assess the strength of grain and phase boundary37,38. To further study the effect of coherent WC/Co phase boundary on the fracture toughness of the nanocrystalline cemented carbides, we calculate and compare the separation energies for various WC/Co phase boundaries. In order to calculate the separation energy, we first construct a model with a coherent WC/Co phase boundary as Fig. 6A, relax it by the conjugate gradient method and record the system’s energy as EWC/Co; then separate the model from the WC/Co phase boundary, relax it and again record the system’s energy as EWC+Co. Finally, the separation energy of the coherent WC/Co phase boundary is calculated as:

Petisme, M. V. G., Johansson, S. A. E. & Wahnström, G. Molecular dynamics simulation of WC/WC grain boundary sliding: the effect of thin cobalt films on sliding resistance. Proc. 18th Int. Plansee Semin. 2, 19 (2013).

“In CVD aluminum-oxide coatings, the atoms are arranged in a hexagonal form. In the past the orientation of the coating’s building blocks were randomly arranged. Today we can control the orientation and bring a harder and tougher structure to the point of the cut. These textured coatings are 15 per cent tougher and 10 per cent harder than the old version. That means as much as 20 per cent more cutting speed or 30 per cent more tool life.”

Furushima, R. et al. Control of WC grain sizes and mechanical properties in WC-FeAl composite fabricated from vacuum sintering technique. Int. Journal of Refractory Metals and Hard Materials 50, 16–22 (2015).

To quantitatively analyze the fracture process of the two models, the crack surface area per volume (i.e., the ratio of the crack surface area to the total volume of the system) is calculated during deformation. We suppose that each crack surface atom contribute (V represents Voronoi volume of a FCC Co or HCP WC atom in perfect lattice) area to the crack surface and the A of such atoms are then summed up as the total crack surface inside the model. The calculated crack surface area per volume as a function of strain for both coherent and incoherent models are shown in Fig. 5, which indicates that both of the two models begin to form cracks almost at the same strain value; and the crack surface area per volume in the coherent model is always smaller than that of the incoherent model at the same strain level. The figure suggests that the coherent WC/Co phase boundary is stronger than the incoherent one and shows higher resistance to intergranular cracking. The difference in the crack surface area per volume between the coherent and incoherent models can well explain why the coherent model’s fracture toughness is higher than that of the incoherent model.

From Fig. 3, we also find that below strain value of 2.1%, the coherent model is in the linear elastic stage, no dislocation can be found. Beyond the strain value of 2.1%, partial dislocations begin to nuclear at the Co grain boundaries and WC/Co phase boundaries, then slip in the Co grains and leave stacking faults (SF) behind them (some SF are highlighted by red circle in Fig. 3B). Below the strain value of 6.6%, the deformation mechanism of the coherent model is similar to that of the incoherent model and this is the underlying reason why the stress-strain curves of the two different models are almost completely overlapped. Form the above analysis we can conclude that before cracks nuclear, the mechanical property of the nanocrystalline WC-Co cermet materials is insensitive to the joint types of the WC/Co phase boundaries. With accumulating high local stress at the WC grain boundaries, cracks begin to nuclear at the triple junction region of the WC grain boundaries at strain value of 6.6%, (some cracks are highlighted by red circle in Fig. 3C), When the model is further deformed from the strain of 6.6% to 26.6%, the cracks will propagate along the WC grain boundaries or incoherent WC/Co phase boundaries, then interconnect with each other and form a main crack. Noteworthily, when the main crack tip arrived at the coherent WC/Co phase boundary (the main crack tip is highlighted by red circle in Fig. 3D), the crack will propagate through the Co phase and form a transcrystaline path rather than along the coherent WC/Co phase boundary. Furthermore, the FCC Co in the present model is equipped with more sliding systems than HCP Co, the dislocations in FCC Co are easier to slide under the stress field of the crack tip, thus crack tip blunting can be achieved34,35,36; subsequently, Co ligament bridging can be formed at the crack tip (Co ligament bridging is highlighted by red circle in Fig. 3E). The high ductility of the FCC Co phase can increase the work of rupture, so increase the fracture toughness of the nanocrystalline WC-Co cemented carbides. To remove statistical uncertainty, other five pairs of incoherent and coherent samples have been further investigated, it is found that coherent WC/Co boundaries indeed increase the probability of transcrystalline path.

Easily access valuable industry resources now with full access to the digital edition of Canadian Metalworking.

Research Institute for Energy Equipment Materials, Hebei University of Technology, Tianjin, 300132, China

Kelchner, C., Plimpton, S. & Hamilton, J. Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 58, 11085–11088 (1998).

Two types of nanocrystalline WC-Co cemented carbide model containing about 2.37 million atoms are generated from Voronoi construction (see methods). The analytical bond order potential (ABOP) for the W–C–Co system20,21 is adopted, which was developed using first principles calculations and experimental data. This type potential has been successfully applied to describe metallic and covalent bonding, as well as to a metal-carbide system22,23,24,25,26. All MD simulations are carried out with LAMMPS code27. MD simulations are conducted using isothermal-isobaric ensemble via Nose-Hoover thermostat28,29 and periodic boundary conditions are imposed in all three directions. The initial constructed models are relaxed at 300 K for 100 picoseconds (the time step is 2 femtosecond) to reach a stable structure. Then the models are deformed in uniaxial tension along x direction until failure at constant strain rates (5 × 108s−1) with a stress-free condition for the other two directions. The stress is calculated using the virial definition without the kinetic portion30,31,32.

Densley, J. M. & Hirth, J. P. Fracture toughness of a nanoscale WC-Co tool steel. Scripta Mater. 38, 239–244 (1997).

Huang, Q. et al. Nanotwinned diamond with unprecedented hardness and stability. Nature 510, 250–253 (2014).

Xu, C. H., Ai, X. & Huang, C. Z. Research and development of rare-earth cemented carbides. Int. J. Refract. Met. Hard Mater. 19, 159–168 (2001).

The separation energies for various WC/Co phase boundaries are displayed in Fig. 6B, from which it can be found that except for WC(0001)/Co(001) phase boundary, the separation energy of the coherent WC(0001)/Co{111} phase boundary is larger than those of incoherent WC/Co phase boundaries, suggesting that the coherent WC(0001)/Co{111} phase boundary is much stronger than the incoherent WC/Co phase boundaries. Therefore, the existence of the coherent WC/Co phase boundary in the nanocrystalline cemented carbides will effectively block the propagation of microcracks along them, increases the probability of transcrystaline path through the FCC Co phase. The high ductility of the FCC Co phase can increase the fracture toughness of the nanocrystalline cemented carbides. Interestingly, we find that the separation energy of WC(0001)/Co(001) phase boundary is a little larger than that of the coherent WC(0001)/Co{111} phase boundary, indicating that if we manage to increase the probability of the WC(0001)/Co(001) phase boundary, we also can increase the fracture toughness of the nanocrystalline cemented carbides.

Hall, E. O. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. London Ser. B 64, 747 (1951).

John Copher, applications engineer at Sumitomo Electric Carbide Inc., said, “Part of my job is answering the engineering hotline, and almost every day someone calls and says they are working with a material we have never heard of before. As a tooling provider, we have to find out what is in the material and work with the caller to assign the grade and coating that will work best. All the old materials are still out there, but there are a lot of new materials in the aerospace, automotive, and medical fields that have caused us to adjust the technology that produces the coatings on the inserts that will cut those materials.”

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

In the present works, the effect of coherency WC/Co phase boundaries on the fracture toughness of the nanocrystalline WC-Co cemented carbides is studied by MD simulation method. The simulation results confirm that the nanocrystalline cemented carbides with coherency WC/Co phase boundaries has higher fracture toughness than that without coherency WC/Co phase boundaries, which is in good agreement with our previous experimental works. Moreover, the mechanism of why coherency WC/Co phase boundaries can improve the fracture toughness of the nanocrystalline WC-Co cemented carbides has also been studied, it is found that the separation energy of the coherent WC/Co phase boundary is larger than those of incoherent WC/Co phase boundaries. Therefore, the coherent WC/Co phase boundary will effectively block the propagation of microcracks along them and increases the probability of transcrystaline path through the FCC Co phase. The high ductility of the FCC Co phase can blunts the crack tip and increases the fracture toughness of the nanocrystalline cemented carbides.

Albe, K., Nordlund, K. & Averback, R. S. Modeling the metal-semiconductor interaction: Analytical bond-order potential for platinum-carbon. Phys. Rev. B 65, 195124 (2002).

Tschopp, M. A. & McDowell, D. L. Influence of single crystal orientation on homogeneous dislocation nucleation under uniaxial loading. J. Mech. Phys. Solids 56, 1806–1830 (2008).

The new-generation steel turning insert grades GC4425 and GC4415 deliver improved performance in every way. Coated with second-generation Inveio® technology, they have a broad range of applications and are recommended for continuous and interrupted cuts. See how our experts worked their magic and learn what drove them to create our recently launched ISO P steel turning grades – GC4415 and GC4425.

Lu, L., Sui, M. L. & Lu, K. Superplastic Extensibility of Nanocrystalline Copper at Room Temperature. Science 387, 1463–1465 (2000).

Bjkas, C. et al. Interatomic potentials for the Be–C–H system. J. Phys. Condens. Matter 21, 445002 (2009).

Follow that path only if you want to lose productivity today.Insert manufacturers, like electronic providers that continually upgrade cell phones and televisions, continually invest in research and development to make their cutting tools do a better job. The upside to not staying with the coating developed a few years ago is that new, more effective coatings add more to the bottom line. The downside, which isn’t really a downside, is that there are many more options to choose from which can make selecting the right cutting tool a bit difficult. Experts at each tooling company save the expanded options from being a problem. They will collect information on the process being used, the material being cut, and the end product being produced to be sure the right coating is selected to provide quality cuts and long-lasting performance.Every shop’s desire is to increase production without losing quality amidst faster machining processes. Lean manufacturing remains a common goal. Lights-out production requires inserts that last until an operator returns to change edges. A job shop gets a job that requires working with a new, difficult material. Chances are the best insert and coating to be used is not an old reliable. These are the types of situations that drive coating research forward.John Copher, applications engineer at Sumitomo Electric Carbide Inc., said, “Part of my job is answering the engineering hotline, and almost every day someone calls and says they are working with a material we have never heard of before. As a tooling provider, we have to find out what is in the material and work with the caller to assign the grade and coating that will work best. All the old materials are still out there, but there are a lot of new materials in the aerospace, automotive, and medical fields that have caused us to adjust the technology that produces the coatings on the inserts that will cut those materials.”3 Main TypesSteve Geisel, senior product manager at Iscar Canada, said that there are three main categories of coatings: chemical vapour deposition (CVD), physical vapour deposition (PVD), and uncoated. CVD coatings are generally thicker and allow machining at higher surface footage, which can be good for machining carbon and alloy steels. PVD coatings are for the high-temperature alloy materials because the coatings are very thin to allow the insert to absorb heat. That quality avoids work hardening that would be caused by heat reflecting back into the cut or chip. Uncoated inserts are used for high temperature applications like titanium because many of the coatings have a titanium layer and the cutting tool needs to be harder than the material being cut.Advances are continually being made in all three categories.Uncoated inserts, along with the CVD and PVD coated inserts, benefit from new substrates. For coated inserts, new chemical formulas continue to make them last longer, be more efficient, and have the ability to cut established and new materials faster.Most of the coatings, nearly 90 per cent according to tooling manufacturers, are multilayer. The elements making up each layer, the thickness of each layer, and the order in which they are applied to the insert dictate what materials they can cut and how long they will last.Tooling manufacturers continually experiment with new mixes of standard coating materials and introduce new elements.“We are starting to use coatings that incorporate rare-earth elements to try to get the coating at a higher hardness than the material being machined,” said Geisel. Iscar’s grade IC6025 structure is for turning ISO M materials. Each layer of the coating and its thickness are chosen to meet a specific need. Photo courtesy of Iscar.The Shape of AtomsStructure of the atoms within the coatings and how each coating adheres to the layer above and below also plays a large role in their effectiveness.Aaron-Michael B. Eller, product manager—ISO turning and advanced materials, Seco Tools LLC, said, “In PVD aluminum titanium nitride or titanium nitride coatings, the atoms are arranged in a cubic form. During use, structural and compositional changes take place. Some are helpful but others are not. By controlling the coating process, we can encourage the good and deter the bad, resulting in increased speed capability and wear resistance.“In CVD aluminum-oxide coatings, the atoms are arranged in a hexagonal form. In the past the orientation of the coating’s building blocks were randomly arranged. Today we can control the orientation and bring a harder and tougher structure to the point of the cut. These textured coatings are 15 per cent tougher and 10 per cent harder than the old version. That means as much as 20 per cent more cutting speed or 30 per cent more tool life.”Copher said the ability of tooling manufacturers to control the crystal orientation keeps the coatings in line with each other. “Controlling the crystal orientation helps the wear resistance, the peeling resistance, and the breakdown of the coating during the machining process.”Visual AdvantageA top layer of coating such as a colourful chrome that wears away to expose the different colour of the layer below can, by itself, provide a significant increase in productivity.“We did a spot check with some of our customers. We would go to a recycle bin, grab a handful of inserts, and check the edges. They were shocked at the number of unused edges that were thrown into the bin,” said Eller. “Simply having used edges visually apparent in contrast to unused edges made it easy for operators to use all edges before tossing an insert. It creates a substantial cost savings.”Some Recent CoatingsUnderstandably, many of the new coatings have been developed to increase production in exotic and difficult-to-machine materials, but not all. Some new coatings boost production for established, more common materials.Iscar’s DO-TECH coating combines the CVD and PVD technologies to create a coating that improves performance when cutting cast iron for milling and turning. Geisel said, “We use a lot of titanium carbides and aluminum oxides. We also use titanium nitride—it’s a good coating to use as a top layer because it’s gold and shows the wear.”Sumitomo’s CVD Absotech™ Platinum coating is a multilayer aluminum oxide/titanium carbon nitride designed mainly to cut carbon steels, tool steels, and stainless steel. Copher said that the Absotech Bronze PVD coating of titanium aluminum silicon nitride is recommended for interrupted machining of stainless steel and exotic materials.Duratomic® from Seco is a CVD aluminum-oxide coating for increased edge toughness, more wear resistance, and smooth surface finishes that are cut with less friction, said Eller. When the insert does begin to wear, the chrome included in its makeup shows the worn edges. Each layer of a nanolaminate PVD coating is approximately 7 nm thick. Varying the individual layer materials and thicknesses makes it possible to adjust the hardness and thermal stability properties. Photo courtesy of Seco Tools LLC.Everything Matters“Whenever we’re working with a manufacturer, we have them show us the machine to be used, specify the material, and show us the workpiece. The workpiece itself is key. Is it an easy shape or some sort of irregular shape that needs counterweights because the part might not run perfectly true? A prime example is the automotive industry because its parts might have lobes or protrusions so they have to be offset when they run. That affects the insert wear. We get a feeling for what type of cutting parameters they can operate safely and then determine the insert and coating. If you run too fast, you can risk throwing a part out of a machine and hurting the operator,” said Geisel.“I’ll ask manufacturers why they are using a particular insert or coating and they say, ‘It’s just what we had.’ That’s understandable if they have only a few pieces to make, but they need to understand that all tooling manufacturers are improving technologies,” Geisel said. “A grade of coating they used 10 years ago is completely different from today’s grades which are much better.”Iscar Canada, 905-829-9000, www.iscar.ca Seco Tools LLC, 248- 528-5457, www.secotools.comSumitomo Electric Carbide Inc., 800-950-5205, www.sumicarbide.com Slide Show | 5 Images

This work is supported by the Natural Science Foundiation of China (Grant No. 51571082), the National Science Fund for Distinguished Young Scholars (No. 51425101) and China Postdoctoral Science Foundation funded project (No. 2015M580191).

“We are starting to use coatings that incorporate rare-earth elements to try to get the coating at a higher hardness than the material being machined,” said Geisel.

In order to further understand the different stress-strain behaviors between the coherent and incoherent models, in this part we study the deformation mechanism of the two models. Figures 2 and 3 give the cross-section views of the incoherent and coherent models during tensile deformation. In the figures atoms are colored by theirs centro-symmetry parameter33. Red lines represent WC (or Co) grain boundaries and incoherent WC/Co phase boundaries; green and blue areas represent WC and Co grains, respectively; green lines in Co grains represent stacking faults; WC/Co phase boundaries without red color represent coherent phase boundaries.

Konyashin, I. et al. On the mechanism of WC coarsening in WC–Co hardmetals with various carbon contentsInt. J. Refract. Met. Hard Mater. 27, 234–243 (2009).

Recently, using nanoscale WC–Co composite powder and the spark plasma sintering technique, a WC-Co cemented carbide bulk with a mean grain size of about 65 nm was synthesized by our group14. This nanocrystalline WC-Co cemented carbide bulk possesses a superior combination of hardness and fracture toughness. By using Vickers hardness tester and indentation method, the hardness and fracture toughness were measured as HV = 2050 ± 10 kg fmm−2 and , respectively; which is more excellent than that of other cemented carbides reported in the literature with the same Co content15,16,17,18,19. It is understandable that the high hardness of the present nanocrystalline WC-Co cemented carbide came from its smaller grain size; however, its high fracture toughness is not well-understand and need further investigation.

Synthetically considering the stress-strain behavior and the deformation mechanism of the two models, we find that the tensile process of the two models can be divided into three different stages: the linear elastic stage (strain value from 0% to 2.1%), plastic stage (from 2.1% to 6.6%) and fracture stage (larger than 6.6%). In the plastic stage, the plastic deformation only occurs in the FCC Co phase rather than WC phase, which indicates that only FCC Co phase can contribute to the plasticity of the two models. Moreover, the stress-strain curves of the two models are almost completely overlapped in the first two stages and different from each other only in the fracture stage; suggesting that the WC/Co coherency phase boundaries only works in the fracture stage rather than in the first two stages.

Gnidenko, A. A. First principle simulation of the Co layers behavior on a surface of hexagonal tungsten carbide. Physics Procedia 23, 132–135 (2012).

Zhou, M. A new look at the atomic level virial stress: on continuum-molecular system equivalence. Proc. Royal Soc. London A. 459, 2347–2392 (2003).

Chang, S. H. & Chen, S. L. Characterization and properties of sintered WC–Co and WC–Ni–Fe hard metal alloys. J. Alloys Comp. 585, 407–413 (2014).

Atoms are colored by theirs centro-symmetry parameter, red lines represent WC grain boundaries and incoherent WC/Co phase boundaries; green and blue areas represent WC and Co grains, respectively; green lines in Co grains represent stacking faults. WC/Co phase boundaries without red color are coherent phase boundaries.

Christensen, M. & Wahnstrom, G. Effects of cobalt intergranular segregation on interface energetics in WC–Co. Acta Mater. 52, 2199–2207 (2004).

Roebuck, B. & Almond, E. A. Deformation and fracture processes and the physical metallurgy of WC–Co hardmetals. Int Met Rev. 33, 90–110 (1988).

College of Materials Science and Engineering, Key Laboratory of Advanced Functional Materials, Education Ministry of China, Beijing University of Technology, Beijing, 100124, China

Atoms are colored by theirs centro-symmetry parameter, red lines represent WC grain boundaries and incoherent WC/Co phase boundaries; green and blue areas represent WC and Co grains, respectively; green lines in Co grains represent stacking faults.

Copher said the ability of tooling manufacturers to control the crystal orientation keeps the coatings in line with each other. “Controlling the crystal orientation helps the wear resistance, the peeling resistance, and the breakdown of the coating during the machining process.”

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

Xie, H., Song, X., Yin, F. et al. Effect of WC/Co coherency phase boundaries on Fracture toughness of the nanocrystalline cemented carbides. Sci Rep 6, 31047 (2016). https://doi.org/10.1038/srep31047

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

Insert manufacturers, like electronic providers that continually upgrade cell phones and televisions, continually invest in research and development to make their cutting tools do a better job. The upside to not staying with the coating developed a few years ago is that new, more effective coatings add more to the bottom line. The downside, which isn’t really a downside, is that there are many more options to choose from which can make selecting the right cutting tool a bit difficult. Experts at each tooling company save the expanded options from being a problem. They will collect information on the process being used, the material being cut, and the end product being produced to be sure the right coating is selected to provide quality cuts and long-lasting performance.

Petisme, M. V. G., Gren, M. A. & Wahnström, G. Molecular dynamics simulation ofWC/WC grain boundary sliding resistance in WC–Co cemented carbides at high temperature. Int. Journal of Refractory Metals and Hard Materials 49, 75–80 (2015).

The effect of coherency WC/Co phase boundaries on the fracture toughness of the nanocrystalline WC-Co cemented carbides is studied by MD simulation method. The simulation results show that the nanocrystalline WC-Co cemented carbides with coherency WC/Co phase boundaries has higher fracture toughness than that without coherency WC/Co phase boundaries. Moreover, the mechanism of why coherency WC/Co phase boundaries can improve the fracture toughness of the nanocrystalline cemented carbides is also investigated. It is found the fact that the separation energy of the coherent WC/Co phase boundary is larger than that of the incoherent WC/Co phase boundaries is the main reason for this excellent mechanical property.

By carefully observing the Fig. 2, we find that below strain value of 2.1%, the model is in the linear elastic stage, no dislocation is found. Beyond 2.1%, partial dislocations begin to nuclear at the Co grain boundaries and WC/Co phase boundaries, subsequently slip in the Co grains and leave stacking faults (SF) behind them (some SF are highlighted by red circle in Fig. 2C). This stage continues to strain value of 6.6%. The activation of dislocations in Co phase can release local stress at the Co grain boundaries and WC/Co phase boundaries, increase the ductility of the nanocrystalline WC-Co cemented carbide. However, because no dislocation activates in WC grains, there must be accumulated high local stress at the WC grain boundaries with the increasing of the strain. When strain value reaches 6.6%, cracks begin to nuclear at the triple junction region of the WC grain boundaries (some cracks are highlighted by red circle in Fig. 2D). When the model is further deformed from the strain value of 6.6% to 26.6%, the cracks will propagate along the grain boundaries or phase boundaries, then interconnect with each other and form a main crack and the propagation of which finally leads to the fracture of the model.

Duratomic® from Seco is a CVD aluminum-oxide coating for increased edge toughness, more wear resistance, and smooth surface finishes that are cut with less friction, said Eller. When the insert does begin to wear, the chrome included in its makeup shows the worn edges.

Iscar’s DO-TECH coating combines the CVD and PVD technologies to create a coating that improves performance when cutting cast iron for milling and turning. Geisel said, “We use a lot of titanium carbides and aluminum oxides. We also use titanium nitride—it’s a good coating to use as a top layer because it’s gold and shows the wear.”

Cross-section views of the atomic configurations of the incoherent model during tensile deformation.

How to cite this article: Xie, H. et al. Effect of WC/Co coherency phase boundaries on Fracture toughness of the nanocrystalline cemented carbides. Sci. Rep. 6, 31047; doi: 10.1038/srep31047 (2016).

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

“I’ll ask manufacturers why they are using a particular insert or coating and they say, ‘It’s just what we had.’ That’s understandable if they have only a few pieces to make, but they need to understand that all tooling manufacturers are improving technologies,” Geisel said. “A grade of coating they used 10 years ago is completely different from today’s grades which are much better.”

Structure of the atoms within the coatings and how each coating adheres to the layer above and below also plays a large role in their effectiveness.

Every shop’s desire is to increase production without losing quality amidst faster machining processes. Lean manufacturing remains a common goal. Lights-out production requires inserts that last until an operator returns to change edges. A job shop gets a job that requires working with a new, difficult material. Chances are the best insert and coating to be used is not an old reliable. These are the types of situations that drive coating research forward.

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Bonache, V., Salvador, M. D., Rocha, V. G. & Borrell, A. Microstructural control of ultrafine and nanocrystalline WC–12Co–VC/Cr3C2 mixture by spark plasma sintering. Ceramics International 37, 1139–1142 (2011).

Erhart, P. & Albe, K. Analytical potential for atomistic simulations of silicon, carbon and silicon carbide. Phys. Rev. B 71, 035211 (2005).

(A–C) display the evolution of total crack for coherent model; while (D,E) and (F) display that of incoherent model.

“Whenever we’re working with a manufacturer, we have them show us the machine to be used, specify the material, and show us the workpiece. The workpiece itself is key. Is it an easy shape or some sort of irregular shape that needs counterweights because the part might not run perfectly true? A prime example is the automotive industry because its parts might have lobes or protrusions so they have to be offset when they run. That affects the insert wear. We get a feeling for what type of cutting parameters they can operate safely and then determine the insert and coating. If you run too fast, you can risk throwing a part out of a machine and hurting the operator,” said Geisel.

Tschopp, M. A., Spearot, D. E. & McDowell, D. L. Atomistic simulations of homogeneous dislocation nucleation in single crystal copper. Model. Simul. Mater. Sci. Eng. 15, 693–709 (2007).

As we know, hardness (or strength) and fracture toughness are the two most important mechanical properties of the structural materials. Most engineering designs call for structural materials that possess both high hardness and high fracture toughness; however, hardening usually compromises the fracture toughness and vice versa39. Grain refinement is one of methods to harden materials because the grain boundaries can effectively obstruct the lattice dislocation motion. However, grain boundary is a much weak part of the material (has low separation energy) and beneficial to form intergranular crack. Therefore, a finer grain size usually results in lower fracture toughness11,12,13. Naturally, increasing the density of high separation energy grain boundaries is a promising way to obtain material with both high hardness (or strength) and high fracture toughness. Following this idea, nanotwinned Cu with both of high strength and high fracture toughness has been synthesized40,41; moreover, ultrahard nanotwinned cubic boron nitride and nanotwinned cubic diamond are also has been successfully obtained42,43. All these outstanding works use twin boundary, which possesses high separation energy, to realize both high hardness (or strength) and high fracture toughness. Our group use coherent WC(0001)/Co{111} phase boundary, which also possesses high separation energy, to successfully synthesize a nanocrystalline cemented carbides with both high hardness and high fracture toughness. Our work is another example to prove that increasing the density of boundaries with high separation energy is a promising way to obtain material with both high hardness (or strength) and high fracture toughness. We can look forward to obtain many other excellent structural materials by following the same idea.

Harjinder, S. & Pandey, O. P. Direct synthesis of nanocrystalline tungsten carbide from scheelite ore by solid state reaction method, Ceramics International, 39, 785–790 (2013).

Xuemei, L. et al. Quantitative characterization of the microstructure and properties of nanocrystalline WC–Co bulk. Scripta Mater. 66, 825–828 (2012)

Hoover, W. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 31, 1695–1697 (1985).

Evolution of crack fraction (crack surface/system volume) with tensile strain for incoherent and coherent models.

Zhu, L. H., Huang, Q. W. & Zhao, H. F. Preparation of nanocrystalline WC-10Co-0.8VC by spark plasma sintering, J Mater Sci Lett. 22, 1631–1633 (2003).

The construction of a nanocrystalline WC-Co cemented carbide model with coherent WC/Co phase boundaries can be divided into three steps. The first step is to construct a model with coherent WC/Co phase boundary (Fig. 7(a)). In order to using periodic boundary condition along the x and y directions, the minimum size of the model along the two directions must be 13.02 nm and 5.50 nm, respectively. In present work, the model sizes along the two directions are 26.04 nm (two times of 13.02 nm) and 27.50 nm (five times of 5.50 nm), respectively; the size along z direction is 17.13 nm (Fig. 7(a)). Because the lattice parameters of the two phases are not identical, the misfit dislocations can be created on the coherent WC/Co phase boundary (insert figure in Fig. 7(a)). In the present model, the Co phase is 13.1 wt.% (20 atom%). Then the model is doubled along z direction and the model size along the x, y and z directions are 26.04 nm, 27.50 nm and 34.26 nm, respectively (Fig. 7b). Finally, Voronoi construction is applied to build the polycrystalline system. 3 × 3 × 4 = 36 “seeds” are randomly distributed along the x, y and z directions, respectively. Grains with random misorientations are generated from the “seeds” and filled the box with about 2.37 million atoms. Using this method, a nanocrystalline WC-Co cemented carbide model with coherent WC/Co phase boundaries (named as coherent model) is constructed (Fig. 7c). Furthermore, a same size nanocrystalline WC-Co cemented carbide model without coherent WC/Co phase boundary (named as incoherent model) is also constructed by using the similar method. The structure of the two models is the same except that one has coherent WC/Co phase boundaries and the other hasn’t, so the different mechanical properties of them must come from the joint types of the WC/Co phase boundaries.

The microstructures of the present nanocrystalline WC-Co cemented carbide are examined by transmission electron microscopy (TEM) and high-resolution TEM, it is found that there are plenty of coherent WC(0001)/Co(111) phase boundaries in the randomly selected areas for TEM observations; these coherent WC/Co phase boundaries have been speculated as the main underlying reason for the high fracture toughness. However, in the literature there still lacks theoretic or experimental works to further investigate the deformation mechanism as well as the relationship between the coherent phase boundaries and the high fracture toughness of the nanocrystalline WC-Co cemented carbide. In the present work, we will study the deformation mechanism of the nanocrystalline WC-Co cemented carbide with and without coherent WC/Co phase boundary by using molecular dynamics (MD) simulation method and discuss the relationship between the high fracture toughness and the coherent WC/Co phase boundaries.

Lin, Z. et al. Nanocrystalline tungsten carbide: As incompressible as diamond. Appl. Phys. Lett. 95, 211906 (2009).

To further study the effect of WC/Co coherency phase boundaries on the fracture process of the two models, the evolution of the total cracks in the two different models during the tensile process are displayed in Fig. 4. As periodic boundary condition is applied to the two models, atoms with large Voronoi volumes can be considered as the atoms located at cracks’ surface. The Voronoi volume of a perfect FCC Co and HCP WC atom are 11.08 Å3 and 10.17 Å3, respectively. In the present works, we use the average value (25.00 Å3) as a critical value to determine whether an atom is at crack surface; atoms with Voronoi volume higher than the critical value are identified as crack surface atoms. From the Fig. 4 it can be found that the microcracks in the two models are nucleated at multiple sites (Fig. 4A,D). For the coherent model, the coherent WC/Co phase boundary maybe block the propagation of microcracks along them, so increases the probability of transcrystaline path through the FCC Co phase. The high ductility of the FCC Co phase can increase the work of rupture and decreases the probability to form a main crack (Fig. 4B,C). However, for the incoherent model, because there are not coherent WC/Co phase boundaries, microcracks will propagate along the grain or phase boundaries, then interconnect with each other and finally form a main crack (Fig. 4E,F).

Bonache, V., Salvador, M. D., Rocha, V. G. & Borrell, A. Microstructural control of ultrafine and nanocrystalline WC–12Co–VC/Cr3C2 mixture by spark plasma sintering. Ceramics International 37, 1139–1142 (2011).

“We did a spot check with some of our customers. We would go to a recycle bin, grab a handful of inserts, and check the edges. They were shocked at the number of unused edges that were thrown into the bin,” said Eller. “Simply having used edges visually apparent in contrast to unused edges made it easy for operators to use all edges before tossing an insert. It creates a substantial cost savings.”

Xiao-Chun, Li. et al. Modified analytical interatomic potential for a W–H system with defects Journal of Nuclear Materials 408, 12–17 (2011).

18581906093

18581906093