why choose 4 flute ball nose end mill instead of 2 flute? - end mill 2 flute vs 4 flute

Home Engineering Book Store Engineering Forum Applications and Design Beam Deflections and Stress Bearing Apps, Specs & Data Belt Design Data Calcs Civil Engineering Design & Manufacturability Electric Motor Alternators Engineering Calculators Excel App. Downloads Flat Plate Stress Calcs Fluids Flow Engineering Friction Engineering Gears Design Engineering General Design Engineering Hardware, Imperial, Inch Hardware, Metric, ISO Heat Transfer Hydraulics Pneumatics HVAC Systems Calcs Economics Engineering Electronics Instrumentation Engineering Mathematics Engineering Standards Finishing and Plating Friction Formulas Apps Lubrication Data Apps Machine Design Apps Manufacturing Processes Materials and Specifications Mechanical Tolerances Specs Plastics Synthetics Power Transmission Tech. Pressure Vessel Pumps Applications Re-Bar Shapes Apps Section Properties Apps Strength of Materials Spring Design Apps Structural Shapes Threads & Torque Calcs Thermodynamics Physics Vibration Engineering Videos Design Manufacture Volume of Solids Calculators Welding Stress Calculations Training Online Engineering

One of the goals of any manufacturer is to have a smooth finishing. This is due to the fact that the smoothness of the finished product enhances not only its style and appearance but also the complete sensation of touching it. As a result, it is an essential requirement for the procedure. It is possible to employ double-cut burrs at slower speeds, which will result in the production of fewer chips. As a consequence of this, they are able to provide a higher quality finishing than single-cut burrs. However, this is dependent on the type of burr and the size that you select. Therefore, one type of double-cut burr might remove more material while leaving a less smooth surface, whilst another type will do the reverse. Although the rate of material removal in single-cut burrs can be rather high, the smooth finishing they produce is not always as good as that of double-cut burrs.

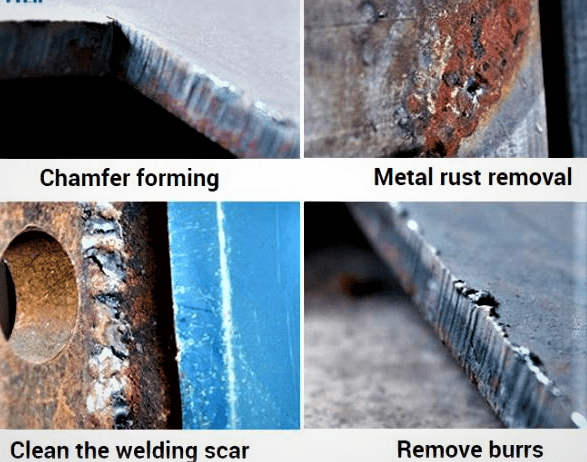

To utilize any of these burrs, the fundamental process, which we will go over in more detail later, is the same. First things first, let’s talk about the several activities in which you may put these burrs to use.

On hard materials, single-cut and double-cut burrs are equally effective. Burrs with a single cutting edge are appropriate for use on ferrous materials. Additionally included are hard materials such as iron, steel, copper, brass, and other similar substances. Well, double-cut burrs are more adaptable. They are suitable for usage on more pliable materials. Because of their compatibility with both metallic and non-metallic surfaces, these burrs have earned the name “adaptable.” They are compatible with materials that are not made of metal, such as plastic, ceramic, or even wood. When working on wood carving projects, a burr with a double cut may produce more desirable results. But you may only use them on soft metals like aluminum, mild steel, and other similar materials.

There is a wide variety of carbide rotary burrs available, each with their own specific form, dimension, and purpose. Additionally, the quality of the burr as well as its overall lifetime can be very different from one manufacturer to the next, which is the primary factor in this variation. Make sure that you pick burrs of the highest quality, regardless of whether you intend to use them on soft or hard fabrics. We offer a tutorial that will walk you through the process of choosing the appropriate tungsten carbide rotary burr. You are free to make use of it!

The functioning of the tool is a significant factor in determining how fruitful your working hours will be. If the carbide burr works quickly and consistently, you may find that your productivity increases. However, your previous job expertise may play a role in determining whether the burr is slower or more difficult to handle.

Carbide burrs cannot be used unless they are mounted to rotating equipment in order to be operated. The carbide burr may be rotated using either a wind-operated or standard electric tool, provided that the speed is sufficient. We like to refer to the burr as a carbide rotary burr since it revolves in a continuous motion at a predetermined speed.

It is important to choose the size and specifications of the carbide rotary burr in accordance with the dimensions of the workpiece as well as the machining allowance. In situations when the machining size is huge and the allowance is large, a cemented carbide rotary burr with a large size should be chosen. Alternatively, a carbide rotary burr with a tiny size might be used.

Carbide rotary burrs are sometimes referred to as carbide high-speed various milling cutters. These milling cutters are designed to work in conjunction with high-speed electric mills or pneumatic tools. The amazing results that can be achieved with the use of carbide rotary burrs have led to their widespread use in a variety of machinery, vehicle, shipbuilding, chemical industry, and craft carving applications. Therefore, understanding how to select a high-quality correct carbide rotary burr is quite vital for those who work in operations and procurement. There are a few different approaches one may use in order to select a proper carbide rotary burr of sufficient grade.

For contour finishing, you can select from among cylinders that have an end cut (i.e., a cutting edge on the end). Cylinder without end cut (flat on the end and no cutting edge) for contour finishing and right-angled corners or a round nose or ball nose shape which is a cylinder-shaped carbide burr but with a rounded head. Both of these shapes are available in a variety of sizes..

When it comes to business sectors, the automotive, aerospace, and metal forging sectors are the most common ones that make use of carbide rotary burrs in their production processes.

Carbide is nothing more than an indestructible compound that is made up of a variety of components, including carbon. In addition, carbide burrs are often manufactured from a high-quality tungsten material that has been subjected to heat treatment. Carbide burrs are able to swiftly cut through strong metals such as tungsten and steel due to their superior abrasion resistance.

Do you work with curved cuts or rounded edges on a regular basis? You may be able to do such duties with the assistance of carbide rotary tree burrs by getting into locations that are difficult to access.

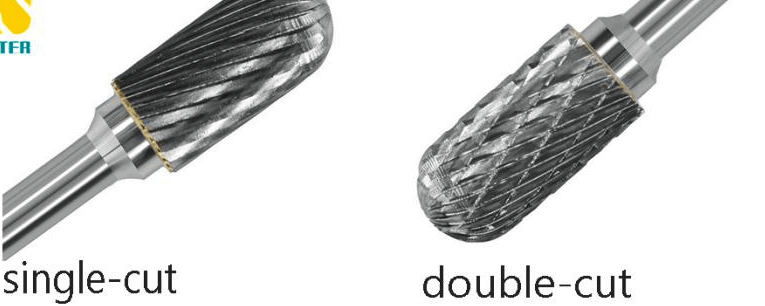

By inspecting the surface of the burr, you may determine whether or not it has a single cut. The texture runs in a single direction along single cut burrs. One of the benefits of using single-cut burrs is that they prevent blockage from occurring during use. When working with materials like aluminum, blockages are something of an everyday occurrence. On the other hand, a single cut burr protects you against this.

The utilization of tungsten carbide rotary burrs is unavoidable for you, whether the activities you perform include little cutting, welding, or shaping, or if the projects you work on involve significant model engineering endeavors. In addition, carbide rotary burrs can be used for debarring, which is the process of removing burrs as well as additional materials and sharp edges from the workpiece.

The single cut burr, also known as the single slot burr, is the most frequent form of tooth used in tungsten rotary carbide burrs. The double cut burr, which may also be referred to as the standard cut or the single groove knife, is the second most prevalent type of tooth. It works better with iron, steel, stainless steel, copper, brass, and other hard things than it does with softer materials. Due to the grain pattern of the single groove, the single-cut is not the best cut to utilise when working with delicate materials. Because the waste that is broken off during the cutting process might easily obstruct the tool groove while it is functioning. As a direct consequence of this, the texture depth of the cut will become shallow, which will lead to a reduction in the capacity to cut. Due to the fact that the single-cut burr results in a greater number of burrs leaping, this technique is not ideal for beginners.

It is important to choose the section form of the carbide rotary burr cutter in accordance with the shape of the workpiece that is going to be processed in order to ensure that the shapes of the two components are compatible with one another. When processing the internal arc surface, a semi-circular burr or round burr (workpiece with a small diameter) should be picked; when processing the inner corner surface, triangular burrs must be chosen; and when processing the internal right angle surface, a flat burr and a square burr can be picked. It is required to create a thin surface (smooth edge) without teeth near to one of the inner right angle surfaces while using a flat burr to cut the inner right angle surface. This is done so that the right angle surface is not damaged.

When selecting the tooth pattern for tungsten steel carbide rotary burrs, it is important to take into consideration the characteristics of the material that will be used for the workpiece. The ideal tool to use for filing soft materials such as aluminum, copper, soft steel, and other similar materials is a carbide burr with a single tooth (milling teeth). A big front angle, a tiny wedge angle, a huge chip retaining groove, a strong chip blocking, and a sharp cutting edge are all characteristics of the single tooth pattern file.

Utilizing the carbide rotary burrs is all there is to using them. As you can see, these burrs are capable of performing a variety of jobs, all of which contribute to making life for manufacturers far more pleasant. HUANA has developed a specialty in the manufacture of carbide rotary burrs. Products employ CNC automatic manufacturing equipment and apply contemporary management mode. At every stage of production, the quality of the product is examined. The overall product quality is superior to that of other businesses in a comparable industry. As a result of this, the vast majority of users have nothing but appreciation for it..

ANSI and ISO Twist drill size chart Fractional and Metric Sizes per. ANSI/ASME B94.11M-1993 below are the standard size drill bits used and readily available in industry. Fractional sizes are measured in inches, while metric sizes are measured in millimeters. The drill size chart contains twist drill data for up to 1.0 inches in diameter.

The double-cut burr, also known as the double-slot burr, cross-cut burr, or double grooves burrs, is a kind of burr that has two parallel cuts. It is simple to wield and manage, making it the perfect tungsten carbide burr tool for those just starting out. Because the grain is crossed, chip removal using a cross pattern is quick, and it is difficult to block the grain while cutting or polishing because the grain is being removed in a crisscross pattern. Additionally, the operating pace would be considerably slower than the typical speed. Things having a low density, such as wood, aluminum, plastic, and some soft objects, are more suited to being fit with a tungsten carbide rotary burr that has a cross-cut. This type of burr is more suitable.

The material may be removed quickly using a single slot burr, which also provides a smooth finishing to the work. For the production of lengthy chips, you may alternatively utilize burrs with a single cut. In addition, you will be able to carry out tasks such as cleaning, milling, debarring, or the removal of material.

If you want to produce concave cuts in your material or form and hollow out an area, you may do it using a carbide burr in the shape of a ball or sphere. Carving jobs that need a high level of detail call for small carbide ball burrs with diameters as small as 0.5 millimeters. These carbide carving burrs may be used in a hobby drill, a micro motor, or a high speed handpiece, and are utilised by a great number of wood carvers, stone carvers, and metal engravers.

Carbide is nothing more than an inorganic compound that is produced by combining carbon with elements that are either semi-metallic or metallic. Carbides are characterized by their high melting points, great hardness, and strong resistance to chemical attack. As a result, they are appropriate for use in cutting instruments as well as abrasives. In the same vein, rotary burrs and carbide burrs with varying cuts are both capable of completing the work at hand. However, the result or the thing that is produced may be different.

You might discover that the single-cut burr is rather difficult to manipulate in your palm. This is due to the fact that the texture runs in a single direction. As a consequence of this, it results in the practise of burr jumping. In a nutshell, missing your position relative to the goal and causing your burr to travel to a new location is what’s meant by the term “burr hopping.” The operation of a single-cut burr can be particularly difficult for novice operators. You will get to experience a performance that is both consistent and smooth while using double-cut burrs. This burr can be handled and managed with a reasonable amount of ease. This burr is so easy to manage that even a novice operator won’t have any problem with it.

The removal of chips or chip extraction is a common technique. Chip extraction is a common step in the manufacturing process of many companies that deal in hard metals. The chip extractor delivers a compressive force to the material so that it may be severed into very small bits, often known as chips. In addition, the process of removing chips involves a variety of steps, including shaping, grinding, and honing, among others. The double-cut method results in additional grooves in the burr. In contrast to single-cut burrs, therefore, they can perform effectively in the process of chip extraction. Therefore, if you conduct jobs related to chip removal on a more regular basis, you may think about purchasing a double-cut burr. Despite this, single-cut burrs are also capable of performing the chip extraction process. However, there is a possibility that the speed and quantity of chip extraction will be significantly reduced.

Because the broken chip may easily block the groove when the single groove burrs operate and cut, the texture of the single groove indicates that it is not very rational for soft things. This is because the depth of the groove texture becomes shallow, which in turn reduces the cutting capacity; The use of a rotary burr with a single groove is recommended for working with iron, copper, steel, and other hard materials.

© Copyright 2000 - 2024, by Engineers Edge, LLC www.engineersedge.com All rights reservedDisclaimer | Feedback Advertising | Contact

Both ferrous and non-ferrous metals may be worked with using burrs that have a double cut. In addition to that, this burr works extremely well on materials that are not metals. Ceramic, plastic, and wood are all considered to be part of it. Due to the increased number of cutting edges, double-cut burrs are capable of performing stock removal at a faster rate. In addition, this burr can give a more finer finishing since it has cuts on both the left and the right. Double-cut burrs have an advantage over single-cut burrs as a result of this feature.

As is common knowledge, carbide rotary burrs may be purchased in a wide variety of sorts, each with its own unique uses, sizes, and forms. Take note that the manner in which one can make use of these burrs is fully dependent, both on their level of comprehension and their level of talent. This indicates that the person who will be handling the burrs should not allow themselves to be constrained by the subsequent descriptions. In a nutshell, the following ideas will only lead you in the right direction and provide assistance in getting started.

It is best suited for objects whose densities are not very high since the double groove has crossing patterns. For example, it may be found in things made of wood, plastic, and metal. Carbide burrs with cross patterns have quick chip removal, and it is not simple to block the groove during grinding or carving, which is why a double groove carbide burr is better ideal for working with pliable materials.

Drill Bits, also called Twist drills are available with straight or tapered shanks though the most common drill bits will have straight shanks.

The convenience and adaptability of these burrs make them an excellent tool for a wide range of jobs and responsibilities. The appearance of their profile is somewhat analogous to that of cylindrical burrs. On the other hand, these burrs include a pointed edge that may be utilized for the creation of precise lines, forms, or grinds. You may utilize this burr in a totally vertical position thanks to the blades that are attached to the top surface of the wheel. In addition, if you want to make the internal surface of bezels look neater, you really need to use this burr.

Product finishing, much like the smoothening operation, produces a more substantial influence in terms of the look and appearance of the final product. Single-cut burrs produce a finishing that is not quite smooth. You may bank on burrs that have been double-cut to give greater finishing. You are able to deal with double-cut bursts at speeds comparable to or even lower than the typical rate. As a result, you will be able to carry out the completing work with more accuracy..

It is recommended that the thickness of the burr teeth be chosen with consideration given to the allowable size of the workpiece, the precision of the machining, and the qualities of the material. For machining workpieces that have a big allowance, low dimensional accuracy, high form and position tolerance, large surface roughness value, and soft material, a carbide burr with coarse teeth is the best option; otherwise, a carbide burr with fine teeth should be chosen. While it is utilized, the machining allowance, dimensional accuracy, and surface roughness requirements of the workpiece should be taken into consideration when selecting it.

There are five key characteristics that may be used to discern between single-cut and double-cut burrs. It covers the capability of chip extraction, the material, the functionality, the operation of smoothing, and the finishing.

18581906093

18581906093