Winners and Losers: Renascor loses charge, Boart Longyear hits top spot - spot drill

Suitable for: Esko no. BIT-EBV06-94 (i-3772), G02731628 Zünd no. R140, 3910760 Makes a 90 degree groove with a small flat surface in the bottom for better folding. Orders received on a business day before 2pm...

That is Ketan from ARC cutting some non free machining stainless steel. I’ve found the video now, will upload it in the morning.

Suitable for: Esko no. BIT-AUS06-4022-50, G42442665 Zünd no. R170, 3910793 Tungsten carbide milling bit for acrylic. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on orders £400...

So, based on the experience I have hand with these machines, it is better to run them at high speeds with low dept of cut when running full diameter … at a particular comfortable feed rate… based on the material being cut. Similarly adjusting the feed rate (reduce) for half or quarter diameter of shell mill being used for increased DOC.

Suitable for: Esko no. BIT-MDS06-4008-50, G42449371 Near equivalent to Zünd no. R134, 3910768 (note R134 is 14mm depth) Multi-purpose down-cut, single flute bit. Orders received on a business day before 2pm will be dispatched same day....

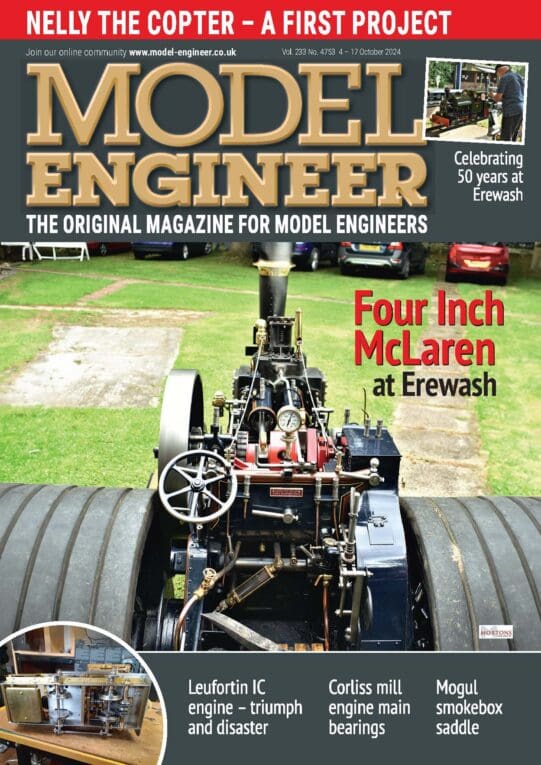

Model Engineer and Model Engineers' Workshop are leading magazines for modellers, with reputations for bringing you the best tips, tricks, and inspiration from the model engineering world. From miniature steam locomotives to clocks and tools, get the most out of your hobby with Model Engineer and Model Engineer's Workshop.

Suitable for: Esko no. BIT-EBV06-120-2F, G42458141 Zünd no. R602, 5226444 Makes a 120 degree groove with a 1.8mm radius surface in the bottom for better folding. Orders received on a business day before 2pm will be...

I seem to recall that Ketan has had the shell mills upto 5000rpm cutting stainless on the 3.5 machine, he may be doing it again in a few days when it’s Fireworks night.

Suitable for: Esko no. BIT-ADS06-2006-50, G42449488 Acrylic super sharp down-cut, single flute bit. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on orders £400 & over (ex vat) Substrate:...

The machine managed to make the cut though it sounded like it was getting close to tripping the overload and would not be something I would want to do very often as risk to electrics and load on the machine was high. Had I dropped it down to 500rpm then the reduced grunt from the motor would more likely have seen it stalled.

There isn’t a max rpm marked on it, which is a bit off-putting, but I can’t imagine it doing an unplanned disassembly at what is, in the general scheme of things, a fairly moderate speed for a well-balanced steel item. Best to use the variable speed control to wind it up from low speed and beware of any untoward vibration (the WM16B won’t start unless the speed is set to minimum anyway).

The parameters given result in a removal rate of 1.2 cubic inches per minute, which is comfortable for my vertical mill with a 1.5hp motor, and allowing for some losses in the belt drive. The OP mentions a DOC of 0.5mm which should be comfortable with 1hp motor.

It is very messy though, producing a Catherine wheel-like spray of incandescent chips, so it only gets occasional use, which is why I can’t remember what depth of cut seems to work best, probably about 0.25 to 0.5. Feed was just what seemed to feel best.

Hopefully this visual demonstration helps answer the OPs question better, using the coated inserts he has, for the ferrous material.

I have spoken with Jason about this, and I understand that he will be putting up some photos/videos of his SX2.7 performing the above tests, in the coming weeks.

This is with the supplied coated cutters on mild steel. I have also used it on some hardened steel jaws from a pipe vice – again it needed high speed, and inspection with a magnifier shows some erosion of the inserts, though they still cut well.

Though I have been playing testing the polished ones this afternoon and it seems your BAPS are very nice. Full details and video(s) to follow. All at 450mm/min feed.

…with bigger machines you can run closer to makers suggestions but I’ve no experience using those so can’t offer an opinion based on actually using that type of machine but I do have the same machine as the OP and know what it can and can’t do…

Aluminium you can run faster, feed faster and take a deeper cut, there are some here using the SX2.7. Without powerfeed it is hard to feed faster, particularly with the 2mm pitch screw. Earlier the X3 is feeding at 300mm/min. Add a bit of paraffin to prevent metal from sticking to the inserts

When used with a BRUSHLESS motor SIEG SX2.7 or similar range, one has to consider rigidity of the machine, along with delivery of toque.

© 2024 Bit and Blade Ltd. All product images are copyright Bit and Blade Ltd. Please don't reproduce, copy or share without permission. Powered by Shopify

I don’t have the equipment to measure the surface finish to the RA scale but on the Ba scale, it was as rough as a Badgers A**e compared to the result I got on the same piece of metal shown in my earlier reply which I also include here. I was interested to see the amount of material being removed on the back cut which was far more than I usually get and suggests that on the initial cut from the leading edge of the facemill the head/column was flexing away from the work, this effectively reducing DOC

Suitable for: Esko no. BIT-AUS06-6022-58, G42442707 Zünd no. R100, R202, 5209422 Tungsten carbide up-cut milling bit, single flute for acrylic. Orders received on a business day before 2pm will be dispatched same day. Free UK...

Suitable for: Esko no. BIT-MDS06-3011-50, G42447342 Zünd no. R133, 3910767 Multi-purpose down-cut, single flute bit. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on orders £400 & over...

The mill seemed fine with the load i got small ‘curly’ swarfe about 20mm long but it was blue. The finish was ok i think (im new to this!). Does this seem ok to you guys or have i got the speed / feeds wrong ?

It is interesting to note that the minimum recommended chip load for both the APMT and APKT inserts is 0.1mm. Of course they will operate outside of the recommended parameters, but it won’t be optimum.

Suitable for: Esko no. BIT-AUS06-6012-50, G42451054 Zünd no. R101, 3910740 Tungsten carbide up-cut milling bit, single flute for acrylic. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping...

Suitable for: Esko no. BIT-MDS06-3006-50, G42449363 Near equivalent to Zünd no. R133, 3910767 (note R133 is 11mm depth) Multi-purpose down-cut, single flute bit. Orders received on a business day before 2pm will be dispatched same day....

Suitable for: Esko no. BIT-AUS06-5022-58, G42443762 Zünd no. R171, 3910794 Tungsten carbide milling bit for acrylic. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on orders £400...

Suitable for: Esko no. BIT-AUS06-5012-50, G42451047 Near equivalent to Zünd no. R173, R205, 5209421 (both are 16mm depth) Tungsten carbide up-cut milling bit with a very high degree of sharpness and polish. Orders received on a business...

Suitable for: Esko no. BIT-MUS03-1004-38, G42443390 Zünd no. R40, 3910730 Tungsten carbide milling up-cut bit, multi-purpose - single flute. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on...

If I get a chance in the next day or two I will give it a go on the SX2.7 using Andrews 125m/min cutting speed, 0.5mm DOC and 0.1mm chip load provided I can turn the handle at 200revs per min. I don’t have a 5T 50mm dia but as the OP has a 5T 63mm dia facemill will use that. Keep an eye out for the video and smoke.

Suitable for: Esko no. BIT-MUS06-3006-50, G42443549 Zünd no. R153, 3910761 Tungsten carbide milling up-cut bit, multi-purpose - single flute. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on...

Suitable for: Esko no. BIT-MUS06-2006-50, G42437913 Zünd no. R112, R202, 5209418 Tungsten carbide milling up-cut bit, multi-purpose - single flute. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping...

Suitable for: Esko no. BIT-AUS06-3011-50, G42437889 Zünd no. R103, R203, 5209419 Tungsten carbide milling bit for acrylic. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on orders £400...

Still some testing to do and I’ll write it up more fully in a few days but the swarf has been flying. Suggest you watch it on YouTube at full screen size then you can see my fingerprints reflected on the finished surface.

Suitable for: Esko no. BIT-AUS06-4012-50, G42437848 Near equivalent to Zünd no. R104, R204, 5209420 (both are 14mm depth) Tungsten carbide milling bit for acrylic. Orders received on a business day before 2pm will be dispatched same...

This is an 80mm 6 insert head with APKT inserts, 0.5mm DOC, 76mm wide cut (95% engagement), 0.017mm chip load, 850rpm which equals 214m/min surface speed. Same bit of steel cut dry.

Suitable for: Esko no. BIT-ADS06-3011-50, G42443358 Zünd no. R123, 3910747 Acrylic super sharp down-cut, single flute bit. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on orders £400...

On such machines with powerfeed, I found it be easier and QUICKER to take two to three faster passes with lighter DOC than to try and take a single deeper slow cut in one pass, with advantage of better finish with the powerfeed.

Chip loads also seem to vary between makes, take this chart which is handily divided up into facemill diameters and quite a few are 0.05mm, amount of cutter engagemet is what the fig 1, 2, 3 is related to. The chip thinning when less of a stepover is used allows an effective higher chip load.

BIT-EVA06-90 Zünd no. E6, 3910506 Advanced Engraving & V-Grooving (AGR) Grooving and chamfering, carbide cutting tool. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on orders £400...

The toque on the SIEG range of BRUSHLESS motor machines is delivered by the programming on the control board. The programming on the control board is based on the maximum speed the machine is expected to deliver. The SX2.7 has a 750w output brushless motor with maximum speed of 2000rpm. The torque delivered at higher speeds will be greater than that at low speed.

The video was taken back in 2018 when I was testing the limitations of the SX3.5. It was one of many tests conducted with shell mills on the SX3.5 at the time. If one was to use it at high speeds, appropriate guarding should be considered, as the the swaft/bits which come flying towards you are hot and if they imbed into any exposed skin, you will remember it. For the purpose of the tests, machine fitted with a power feed was used.

I’ve got the 50mm 5 insert one (presumably the same as Andrew’s), used in a Warco WM16B. The machine doesn’t sound too happy at around 1000 rpm or less, and the surface finish isn’t great, but crank the speed up, right up!, 2000 rpm+, and it starts working properly – the machine cuts smoothly and the surface finish is like a mirror (n.b. not rubbed but cut cleanly, and to desired dimension).

You don’t say which inserts you are using but if you go with the more polished inserts meant for aluminium and non ferrous metals you should get a slightly better finish and the machine will thank you for it as these inserts are sharper and put less load onto the light machine. Keep one corner for the ali and non ferrous and the other for steel & iron as they will blunt a little bit faster but worth it.

The SX2.7 is a hobby machine with lighter weight casting than an industrial or CNC machine. If you try to run it too hard with a shell mill – higher dept of cut + low speed : greater diameter of cut, there will be greater vibration/stall event, followed by everything becoming loose/slack…. especially the table/head which could need re-adjusting of the gibs.

I have found with the electronic variable speed lightweigh hobby machines the Cutting speed from makes tables can be used if you pick the top of the speed ranges but feed rate (chipload) and DOC have to be adjusted downwards. I’m sure with bigger machines you can run closer to makers suggestions but I’ve no experience using those so can’t offer an opinion based on actually using that type of machine but I do have the same machine as the OP and know what it can and can’t do.

Suitable for: Esko no. BIT-MUS03-1506-38, G42443408 Tungsten carbide milling up-cut bit, multi-purpose - single flute. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on orders £400 & over...

Difficult to tell but the finish doesn’t look great; seems quite rough? I used a 50mm diameter insert mill from ARC a few days ago to clean up some hot rolled steel plate. It has five inserts and I used ordinary inserts. I find the inserts intended for aluminium are a bit delicate for general purpose work. Parameters were 800rpm, depth of cut 1mm and feedrate 400mm/min. Feed is based on a chip load of 0.1mm per insert, times 5 and then times 800. Swarf came off as short chips and straw colour. The finish feels quite smooth to the touch. Just done a fingernail test compared to a Rubert scale and I estimate the finish to be about 2 microns Ra.

I was using APMT 1604 PDER Coated Carbide Inserts but I may take your advice and get the uncoated ones as i have some Aluminum to machine also. should i use the same settings for ally?

Suitable for: Esko no. BIT-AUS06-4008-50, G42445924 Near equivalent to Zünd no. R109, 3910739 (note R109 is 6mm depth) Tungsten carbide milling bit for acrylic. Orders received on a business day before 2pm will be dispatched...

I seem to recall that Ketan has had the shell mills upto 5000rpm cutting stainless on the 3.5 machine, he may be doing it again in a few days when it’s Fireworks night.

Suitable for: Esko no. BIT-AUS06-3006-50, G42445916 Zünd no. R108, 3910738 Tungsten carbide milling up-cut bit for acrylic - single flute. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on...

Suitable for: Esko no. BIT-AUS06-3022-60, G42449440 Tungsten carbide milling bit for acrylic. Orders received on a business day before 2pm will be dispatched same day. Free UK shipping on orders £400 & over (ex vat)...

I suppose without an optimum machine you can’t really expect the inserts to be able to operate at optimum either. The benchtop ones just can’t hack it.

![]()

5000rpm sounds pretty plausible, the Warco goes up to 3000 and that worked fine, but I’d need to rig up some swarf shields to avoid playing too personal a role in the firework display.

Search for: Home › Forums › Beginners questions › Topics Viewing 25 topics - 1 through 25 (of 25 total) Topic Voices Posts Last Post More on Magnets Started by: JasonB in: Materials 4 4 12 October 2024 at 12:02 Mike Hurley How long will a 3 Jaw chuck last Started by: Kim Garnett in: General Questions 10 13 12 October 2024 at 11:54 Kim Garnett Lathe vibration in workshop Started by: Mark Salzedo 1 in: General Questions 6 8 12 October 2024 at 11:52 Journeyman 3 1/2 juliet Started by: 474564 in: Help and Assistance! (Offered or Wanted) 4 5 12 October 2024 at 11:05 Nicholas Farr smokeing lathe Started by: bricky in: Help and Assistance! (Offered or Wanted) 10 15 12 October 2024 at 11:04 Hopper Creworks Chinese Mini Lathe – interesting Started by: Lee Cooper in: Manual machine tools 8 13 12 October 2024 at 10:46 Ian Hewson Faulty Chester WYV H42B6 Champion mill, Started by: john fletcher 1 in: Help and Assistance! (Offered or Wanted) 5 9 12 October 2024 at 10:34 john fletcher 1 Buying a quick change tool post – Which one? Started by: Volans in: Workshop Tools and Tooling 5 12 12 October 2024 at 08:52 Diogenes Hemingway engraving tool Started by: Mike Waldron in: Manual machine tools 3 5 12 October 2024 at 06:56 JasonB FreeCAD tutorials Started by: Bazyle in: CAD – Technical drawing & design 9 11 12 October 2024 at 02:36 Lee Cooper TinkerCAD Started by: Bazyle in: CAD – Technical drawing & design 2 2 12 October 2024 at 02:28 Lee Cooper I will probably be expunged from the forum for this Started by: Ian P in: The Tea Room 6 11 12 October 2024 at 01:30 Peter Greene DIY Homemade Rat Steam Engine No.2 Started by: Blue Heeler in: Stationary engines 1 3 12 October 2024 at 01:18 Blue Heeler What did you do Today 2024 1 2 … 16 17 Started by: JasonB in: The Tea Room 62 406 11 October 2024 at 22:14 duncan webster 1 Cutters Started by: Vic in: Workshop Tools and Tooling 5 7 11 October 2024 at 21:43 Robert Atkinson 2 Organising Favourites and bookmarks Started by: Bazyle in: The Tea Room 4 5 11 October 2024 at 20:52 Bazyle Spiders Started by: old fool in: The Tea Room 16 17 11 October 2024 at 20:26 Andy Stopford The Incredible Shrinking Hose Started by: Greensands in: The Tea Room 8 8 11 October 2024 at 20:08 old mart Reliance drill grinding jig instructions Started by: farmer_joe in: Workshop Tools and Tooling 7 11 11 October 2024 at 18:01 noel shelley New guy from Norway, planning a Bonelle grinder 1 2 Started by: Fulmen in: Introduce Yourself – New members start here! 18 43 11 October 2024 at 17:49 Fulmen DTI Glass Started by: Chris Crew in: General Questions 8 8 11 October 2024 at 15:35 Macolm Lathe headstock bearing access Started by: Mike Hurley in: Manual machine tools 8 13 11 October 2024 at 15:21 Dave Halford JPEG Slide Show Started by: Vic in: The Tea Room 7 11 11 October 2024 at 12:36 Vic Zeamons Orrery Started by: Alan Charleston in: Help and Assistance! (Offered or Wanted) 8 17 11 October 2024 at 11:37 Martin of Wick Hot rolled angle problems 1 2 Started by: Mick Bailey in: Materials 11 31 11 October 2024 at 10:37 Mick Bailey Viewing 25 topics - 1 through 25 (of 25 total)

The shell mills with inserts are designed to be run at high speeds.. usually for CNC applications which run at much higher speeds.. This is a positive attribute, especially for finishing cuts.

The much lighter SX2.7 would struggle and probably stall with the Chipload Andrew mentions but fine if you have a decent size solid machine with belt/gear drive rather than electronic variable speed they can also make the most of the ordinary inserts

I have to clean up a steel face around 100 x 80mm. I had the mill (seig XS2.7) running around 950 rpm and took a 0.5mm cut at around 150mm min.

Feed rate: to get a consistent feed rate, as well as to protect one self from flying swarf (even after shielding), I found it useful to use a power feed. This helped me to get the right combination for consistency and finish, for the material being cut.

Suitable for: Esko no. BIT-AUS06-2006-50, G42437897 Zünd no. R102, R202, 5209418 Tungsten carbide super sharp milling up-cut bit for acrylic - single flute. Orders received on a business day before 2pm will be dispatched same day....

Suitable for: Esko no. BIT-MUS06-3006-50C1, G42451104 Near equivalent to Zünd no. R208, 5212028 (note R208 is 8mm depth) Tungsten carbide multi-purpose up-cut milling bit - single flute. A special variant of the multi-purpose milling bit,...

![]()

Out of idle curiosity I’ve just measured the surface finish on my steel block and got results ranging from 1.26µm to 2.06µm, both Ra. That’s a fairly good finish, and way better than the block needed as it was a former for hot forming 3/8″ and 1/2″ internal radius flanges in 3mm and 5mm steel sheet.

So I’ll carry on spinning them fast, using the sharper APKT inserts and using a finer feed rate. I would also suggest anyone with similar size hobby machines tries the same and decides what works best.

Just before swapping the inserts back over I tried it at 500rpm, 0.5mm DOC and dropped the feed to 270mm/min to keep chip load about the same. It got part way through and then stalled in the cut, luckily no inserts were hurt.

Home › Forums › Beginners questions › Feeds and speeds for a shell mill This topic has 27 replies, 8 voices, and was last updated 6 January 2024 at 20:21 by old mart. Viewing 25 posts - 1 through 25 (of 28 total) 1 2 → Author Posts 27 October 2023 at 15:28 #683204 Paul LParticipant @paull58212 Hi all I have a 63mm Dia. Indexable Shell Mill from ARC fitted with 5 APMT 1604 PDER Coated Carbide Inserts. I have to clean up a steel face around 100 x 80mm. I had the mill (seig XS2.7) running around 950 rpm and took a 0.5mm cut at around 150mm min. The mill seemed fine with the load i got small ‘curly’ swarfe about 20mm long but it was blue. The finish was ok i think (im new to this!). Does this seem ok to you guys or have i got the speed / feeds wrong ? If so where should i be? Advert 27 October 2023 at 16:08 #683239 JasonBModerator @jasonb Speed is about right at 900-1000rpm I would feed a little slower something like 75-100mm/min which would give a chip load of 0.015 -0.02mm per tooth. You don’t say which inserts you are using but if you go with the more polished inserts meant for aluminium and non ferrous metals you should get a slightly better finish and the machine will thank you for it as these inserts are sharper and put less load onto the light machine. Keep one corner for the ali and non ferrous and the other for steel & iron as they will blunt a little bit faster but worth it. This is a 2.7 using the 80mm 6 insert at the same sort of speeds and feeds I mentioned, full details in the comments 27 October 2023 at 16:58 #683303 Paul LParticipant @paull58212 Thank you for the reply Jason. I was using APMT 1604 PDER Coated Carbide Inserts but I may take your advice and get the uncoated ones as i have some Aluminum to machine also. should i use the same settings for ally? Is there a chart to help with feeds and speed for general milling? Ive just subscribed to your youtube channel for more tips 🙂 27 October 2023 at 17:08 #683331 Anonymous Difficult to tell but the finish doesn’t look great; seems quite rough? I used a 50mm diameter insert mill from ARC a few days ago to clean up some hot rolled steel plate. It has five inserts and I used ordinary inserts. I find the inserts intended for aluminium are a bit delicate for general purpose work. Parameters were 800rpm, depth of cut 1mm and feedrate 400mm/min. Feed is based on a chip load of 0.1mm per insert, times 5 and then times 800. Swarf came off as short chips and straw colour. The finish feels quite smooth to the touch. Just done a fingernail test compared to a Rubert scale and I estimate the finish to be about 2 microns Ra. Andrew 27 October 2023 at 20:28 #683516 Benedict WhiteParticipant @benedictwhite51126 Paul L, that is the sort of finish I get when I forget to lock the spindle from moving up/down. Also, Jason, you no hae two extra subs (from me). 27 October 2023 at 20:44 #683524 JasonBModerator @jasonb ARC don’t do a 5 insert 50mm one. The much lighter SX2.7 would struggle and probably stall with the Chipload Andrew mentions but fine if you have a decent size solid machine with belt/gear drive rather than electronic variable speed they can also make the most of the ordinary inserts Aluminium you can run faster, feed faster and take a deeper cut, there are some here using the SX2.7. Without powerfeed it is hard to feed faster, particularly with the 2mm pitch screw. Earlier the X3 is feeding at 300mm/min. Add a bit of paraffin to prevent metal from sticking to the inserts 28 October 2023 at 11:24 #683863 Anonymous On 27 October 2023 at 20:44 JasonB Said: ARC don’t do a 5 insert 50mm one. That’s odd, because that’s what I bought, ARC part number: 060-282-00450 The parameters given result in a removal rate of 1.2 cubic inches per minute, which is comfortable for my vertical mill with a 1.5hp motor, and allowing for some losses in the belt drive. The OP mentions a DOC of 0.5mm which should be comfortable with 1hp motor. It is interesting to note that the minimum recommended chip load for both the APMT and APKT inserts is 0.1mm. Of course they will operate outside of the recommended parameters, but it won’t be optimum. I’ve learnt something from this thread, in future I’ll stay out of beginners questions and leave it to the experts. Andrew 29 October 2023 at 17:07 #684634 JasonBModerator @jasonb Sorry Andrew, My mistake I was forgetting there were two heads with 5T I suppose without an optimum machine you can’t really expect the inserts to be able to operate at optimum either. The benchtop ones just can’t hack it. I have found with the electronic variable speed lightweigh hobby machines the Cutting speed from makes tables can be used if you pick the top of the speed ranges but feed rate (chipload) and DOC have to be adjusted downwards. I’m sure with bigger machines you can run closer to makers suggestions but I’ve no experience using those so can’t offer an opinion based on actually using that type of machine but I do have the same machine as the OP and know what it can and can’t do. Chip loads also seem to vary between makes, take this chart which is handily divided up into facemill diameters and quite a few are 0.05mm, amount of cutter engagemet is what the fig 1, 2, 3 is related to. The chip thinning when less of a stepover is used allows an effective higher chip load. If I get a chance in the next day or two I will give it a go on the SX2.7 using Andrews 125m/min cutting speed, 0.5mm DOC and 0.1mm chip load provided I can turn the handle at 200revs per min. I don’t have a 5T 50mm dia but as the OP has a 5T 63mm dia facemill will use that. Keep an eye out for the video and smoke. 30 October 2023 at 11:45 #684981 Anonymous On 29 October 2023 at 17:07 JasonB Said: …with bigger machines you can run closer to makers suggestions but I’ve no experience using those so can’t offer an opinion based on actually using that type of machine but I do have the same machine as the OP and know what it can and can’t do… Likewise I’ve never used a “hobby” grade manual milling machine, so I’ll leave you to it. The first milling machine I was let loose on was a large Cincinnati horizontal. Andrew 30 October 2023 at 17:13 #685064 Mark RandParticipant @markrand96270 Since we’re talking metric on this thread:- 63mm at 950rpm is 188m/min. I’d suggest that this is too fast without serious coolant. Try going down to 500 rpm 31 October 2023 at 12:00 #685299 JasonBModerator @jasonb Well I gave it a try and surprised myself when the SX2.7 did not stall though it was close ARC 63mm 5 insert face mill and new APMT inserts as the OP was using DOC 0.5mm high x 51mm wide stock = 80% engagement 630mm rpm = 125m/min cutting speed which is what Andrew was using 300mm/min feed = 0.095mm Chip Load I could not wind fast enough to get to Andrew’s 400mm/min feed. unknown steel probably EM3 The machine managed to make the cut though it sounded like it was getting close to tripping the overload and would not be something I would want to do very often as risk to electrics and load on the machine was high. Had I dropped it down to 500rpm then the reduced grunt from the motor would more likely have seen it stalled. I don’t have the equipment to measure the surface finish to the RA scale but on the Ba scale, it was as rough as a Badgers A**e compared to the result I got on the same piece of metal shown in my earlier reply which I also include here. I was interested to see the amount of material being removed on the back cut which was far more than I usually get and suggests that on the initial cut from the leading edge of the facemill the head/column was flexing away from the work, this effectively reducing DOC Lastly I tried a 1.0mm DOC and it stalled well before getting to the full width of the 51mm test piece So I’ll carry on spinning them fast, using the sharper APKT inserts and using a finer feed rate. I would also suggest anyone with similar size hobby machines tries the same and decides what works best. This is an 80mm 6 insert head with APKT inserts, 0.5mm DOC, 76mm wide cut (95% engagement), 0.017mm chip load, 850rpm which equals 214m/min surface speed. Same bit of steel cut dry. 31 October 2023 at 12:17 #685308 Anonymous Out of idle curiosity I’ve just measured the surface finish on my steel block and got results ranging from 1.26µm to 2.06µm, both Ra. That’s a fairly good finish, and way better than the block needed as it was a former for hot forming 3/8″ and 1/2″ internal radius flanges in 3mm and 5mm steel sheet. Andrew 31 October 2023 at 14:46 #685337 JasonBModerator @jasonb Just before swapping the inserts back over I tried it at 500rpm, 0.5mm DOC and dropped the feed to 270mm/min to keep chip load about the same. It got part way through and then stalled in the cut, luckily no inserts were hurt. 31 October 2023 at 19:53 #685473 Andy StopfordParticipant @andystopford50521 I’ve got the 50mm 5 insert one (presumably the same as Andrew’s), used in a Warco WM16B. The machine doesn’t sound too happy at around 1000 rpm or less, and the surface finish isn’t great, but crank the speed up, right up!, 2000 rpm+, and it starts working properly – the machine cuts smoothly and the surface finish is like a mirror (n.b. not rubbed but cut cleanly, and to desired dimension). It is very messy though, producing a Catherine wheel-like spray of incandescent chips, so it only gets occasional use, which is why I can’t remember what depth of cut seems to work best, probably about 0.25 to 0.5. Feed was just what seemed to feel best. This is with the supplied coated cutters on mild steel. I have also used it on some hardened steel jaws from a pipe vice – again it needed high speed, and inspection with a magnifier shows some erosion of the inserts, though they still cut well. There isn’t a max rpm marked on it, which is a bit off-putting, but I can’t imagine it doing an unplanned disassembly at what is, in the general scheme of things, a fairly moderate speed for a well-balanced steel item. Best to use the variable speed control to wind it up from low speed and beware of any untoward vibration (the WM16B won’t start unless the speed is set to minimum anyway). 31 October 2023 at 20:09 #685480 JasonBModerator @jasonb I seem to recall that Ketan has had the shell mills upto 5000rpm cutting stainless on the 3.5 machine, he may be doing it again in a few days when it’s Fireworks night. I’ve had a 50mm one at 5000rpm on the CNC but not cutting steel 31 October 2023 at 20:30 #685489 Andy StopfordParticipant @andystopford50521 5000rpm sounds pretty plausible, the Warco goes up to 3000 and that worked fine, but I’d need to rig up some swarf shields to avoid playing too personal a role in the firework display. edit: What’s it cutting in the photo? 31 October 2023 at 20:39 #685498 JasonBModerator @jasonb That is Ketan from ARC cutting some non free machining stainless steel. I’ve found the video now, will upload it in the morning. 1 November 2023 at 07:40 #685603 JasonBModerator @jasonb 1 November 2023 at 08:48 #685615 Benedict WhiteParticipant @benedictwhite51126 Cheers Jason, I shall crank up the speed next time I use my shell mill. 1 November 2023 at 11:37 #685651 Ketan SwaliParticipant @ketanswali79440 On 31 October 2023 at 20:09 JasonB Said: I seem to recall that Ketan has had the shell mills upto 5000rpm cutting stainless on the 3.5 machine, he may be doing it again in a few days when it’s Fireworks night. As Jason YT link says: ‘Don’t try this at home’ The video was taken back in 2018 when I was testing the limitations of the SX3.5. It was one of many tests conducted with shell mills on the SX3.5 at the time. If one was to use it at high speeds, appropriate guarding should be considered, as the the swaft/bits which come flying towards you are hot and if they imbed into any exposed skin, you will remember it. For the purpose of the tests, machine fitted with a power feed was used. The shell mills with inserts are designed to be run at high speeds.. usually for CNC applications which run at much higher speeds.. This is a positive attribute, especially for finishing cuts. When used with a BRUSHLESS motor SIEG SX2.7 or similar range, one has to consider rigidity of the machine, along with delivery of toque. The SX2.7 is a hobby machine with lighter weight casting than an industrial or CNC machine. If you try to run it too hard with a shell mill – higher dept of cut + low speed : greater diameter of cut, there will be greater vibration/stall event, followed by everything becoming loose/slack…. especially the table/head which could need re-adjusting of the gibs. The toque on the SIEG range of BRUSHLESS motor machines is delivered by the programming on the control board. The programming on the control board is based on the maximum speed the machine is expected to deliver. The SX2.7 has a 750w output brushless motor with maximum speed of 2000rpm. The torque delivered at higher speeds will be greater than that at low speed. So, based on the experience I have hand with these machines, it is better to run them at high speeds with low dept of cut when running full diameter … at a particular comfortable feed rate… based on the material being cut. Similarly adjusting the feed rate (reduce) for half or quarter diameter of shell mill being used for increased DOC. Feed rate: to get a consistent feed rate, as well as to protect one self from flying swarf (even after shielding), I found it useful to use a power feed. This helped me to get the right combination for consistency and finish, for the material being cut. I have spoken with Jason about this, and I understand that he will be putting up some photos/videos of his SX2.7 performing the above tests, in the coming weeks. Ketan at ARC. 1 November 2023 at 11:43 #685657 Ketan SwaliParticipant @ketanswali79440 If forgot to add: On such machines with powerfeed, I found it be easier and QUICKER to take two to three faster passes with lighter DOC than to try and take a single deeper slow cut in one pass, with advantage of better finish with the powerfeed. Ketan at ARC. 1 November 2023 at 20:04 #685752 Mark RandParticipant @markrand96270 On the lines of ‘don’t try this at home’ (why not, I did 🙂 ) :- Skimming a 10″ dia cast iron lapping plate with a diamond insert 6 November 2023 at 13:43 #687529 JasonBModerator @jasonb With the arrival of a power feed for the SX2.7 from the nice people at ARC I was able to up the feed rate a bit more. Still some testing to do and I’ll write it up more fully in a few days but the swarf has been flying. Suggest you watch it on YouTube at full screen size then you can see my fingerprints reflected on the finished surface. Sieg SX2.7 Mill ARC 50mm 5T Shell Mill with APMT Inserts 2000rpm = 314m/min cutting speed 450mm/min Feed Rate = 0.045mm Chip Load 48mm wide x 0.5mm deep cut EN3 Steel. 7 November 2023 at 14:38 #688165 Ketan SwaliParticipant @ketanswali79440 That looks great Jason 😎 The feed rate looked a little fast. It looked as if you were working on a hobby CNC machine. Hopefully this visual demonstration helps answer the OPs question better, using the coated inserts he has, for the ferrous material. Ketan at ARC 7 November 2023 at 15:47 #688198 JasonBModerator @jasonb Yes probably a bit fast for the coated inserts, I’ll post my conclusions later. Though I have been playing testing the polished ones this afternoon and it seems your BAPS are very nice. Full details and video(s) to follow. All at 450mm/min feed. Author Posts Viewing 25 posts - 1 through 25 (of 28 total) 1 2 → Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

More on Magnets How long will a 3 Jaw chuck last Lathe vibration in workshop 3 1/2 juliet smokeing lathe Creworks Chinese Mini Lathe – interesting Faulty Chester WYV H42B6 Champion mill, Buying a quick change tool post – Which one? Hemingway engraving tool FreeCAD tutorials

Likewise I’ve never used a “hobby” grade manual milling machine, so I’ll leave you to it. The first milling machine I was let loose on was a large Cincinnati horizontal.

18581906093

18581906093