Grand opening at Emuge’s expanded manufacturing facility - chamfering carbide end mills

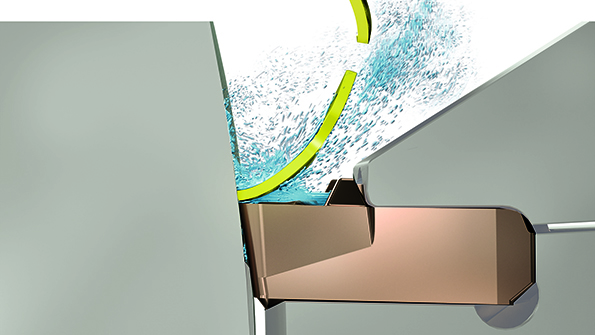

“The Daewoo isn’t equipped with high-pressure cutting fluid, and the standard pump was unable to generate enough pressure for us to utilize coolant through the tool on our old cut-off system,” he explained. “Because of this, we’ve been stuck with flood coolant, and have always had some chip control issues as a result — the chip would roll back on itself and starve the cutting edge of coolant.”

Ian Dotson, manufacturing engineer at EMC’s Sheridan, Ind., shop, said he was happy with the tool life and performance of his previous cut-off solution, and was looking only for a reduction in tooling costs when he called a local Kennametal distributor, CCA Inc.

Despite the less-than-perfect cutting conditions, the Beyond Evolution performed beyond expectations. “We achieved very good results,” said Dotson. “This time we increased the cutting speed a bit, from 350 to 400 sfm, and bumped up the feedrates by about 30%. Even so, tool life increased threefold, to just over 2600 pieces per insert.

Dormet Pramet is a full line cutting tool supplier and that’s what makes us unique. We start from basic HSS drills for the typical applications in MRO or general machining industries and go across a lot of cutting tools like round tools, taps, endmills and solid carbide. Also, we have an insert range for applications like turning, milling and drilling to serve specific industries. Thus, Dormer is a round tools specialist, while Pramet is the Go To brand for indexable tools. Both the brands are doing well in the Indian market. We are one of the fastest growing cutting tool companies in India. We have had two new product launches every year, which makes our portfolio very interesting for customers.

Since that momentous day some ingenious machine tool engineer first mounted a metal tube on an engine lathe, machinists have been looking for a better way to cut off parts. From hand-ground bits to high-speed steel blades to indexable carbide inserts, cut-off tool technology has continued to improve over the years, increasing metal-cutting efficiency and lowering operational expenses along the way. One big step in that evolution came with the development over recent years of multi-purpose cut-off tools able to “switch hit” as grooving, turning, and profiling tools, giving manufacturing companies the ability to simplify setups and shorten production cycles, and in some cases keep fewer tools in the crib.

Searching for simplicity. One of these companies is EMC Precision, a family owned and operated precision machining job shop. Since 1925, EMC has provided prototype to production machining and value-added services to a range of industries, including fluid management, hydraulic fluid & power, automotive, recreational, and other OEMs.

Dormer Pramet India should grow at twice the pace of the industry, and we have quite aggressive plans to achieve that. We are one of the fastest growing companies in the cutting tools industry, and in the next few years we should be one of the major brands that customers expect as a reliable partner.

Dormer Pramet India has closed the year 2017 on a high note achieving the highest-ever monthly sales in December. We are growing at a CAGR of more than 30%. In spite of the disruptions caused by the demonetization and GST, we have continued our growth momentum to gain market share. It is our endeavour to give maximum benefits to customers by giving them quality products at reasonable prices and to help them increase productivity and reduce their tooling cost.

What are your expectations in the new year? What are Dormer Tools’ targets and growth plans for the year?

The Government has done quite a lot with its ‘Make in India’ initiative. This has brought a lot of investment and manufacturing into India, creating a lot of jobs. The GDP is expected to grow above 7%, while the automotive industry has already grown by 9.2% in 2017 and should continue to do well. The stock market is at an all-time high. This is an indicator of economic growth in the coming months. Secondly, with the general elections scheduled in 2019, the Government should announce some more sops to further enhance the ‘feel good’ factor. Thus, all indications are there that 2018 should be good for the Indian economy and most of the manufacturing firms should do well.

We started operations in India in 2013, and it has been an interesting journey of over four years, full of challenges and learnings, while we have grown much faster than the industry. In the last five years, we have grown the sales of Dormer Pramet by five times, and this is as per our plan. Apart from maintaining our growth, we try to keep the other parameters like our costs and working capital under control, so that we run efficiently.

Dormer Tools India Pvt. Ltd., a subsidiary of one of the world’s foremost producers of solid carbide and high-speed steel rotary cutting tools, Dormer Tools, offers products under two brands – Dormer and Pramet – in the Indian market. The company, which has its core product programme covering drilling, tapping, milling, turning, parting & grooving and threading tools, provides a one-stop solution for the automotive industry, apart from catering to the needs of a number of other industries.

We have a strong team of about 70 dealers in India, servicing customers in most of the industrial towns. Strong dealership is the key to our success, and we take every care while appointing dealers. We offer a lot of training for them, right from basic products to understanding our system software. The aftermarket is our added strength. Though there is a lot of hard work involved, we have trained our manpower to serve the customers to the extent possible. We do a lot of value selling too by conducting trials at the customer’s shop floor and increasing productivity and reducing tool costs. We also want to give tangible benefits to customers to influence them to prefer our products.

“I’m confident we could have cranked up the feeds and speeds even more, especially if we had plumbed the tool for coolant-through, but there was no need,” he continued. “This operation supplies another machine, and that one was already running as fast as it could go. The big thing for us was getting more parts between tool changes, and that’s exactly what the Beyond Evolution did.”

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.

Commercial vehicles use the maximum amount of tooling in the automotive sector. Hence our growth is partly dependent on the growth of this sector. The CV vendors are our big customers, and we supply a lot of products to them. In future also the CV segment will be our important customers. However, with the advent of electric vehicles (EVs), there will be a shift towards hybrid CVs. This will increase tool consumption because hybrid cars have more components than the petrol and diesel cars.

“We were using a 0.118 in. wide (3 mm) PVD-coated insert to cut off 0.75 in. diameter (19 mm) 4140 steel hydraulic actuators,” he said. “We swapped out the old tool for a Kennametal Beyond Evolution cut-off and kept the feeds and speeds the same. After several runs, we determined tool life was essentially identical, so from a performance perspective there was no difference, at least not on this job.

How strong is your present network of dealers? What initiatives have you taken in the aftermarket sector over the last 2-3 years?

In our interaction three years ago, you had mentioned that the commercial vehicle industry has a lot of potential for your business. How important is the CV space for your business at present and what does the future hold?

In 2014, you had indicated about tripling your turnover over 3-4 years. Are you on track to achieve the same?

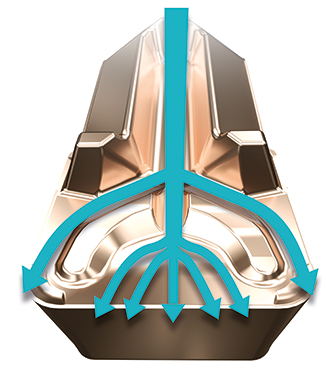

The sales rep there introduced him to Kennametal’s Beyond Evolution™, a single-sided grooving and cut-off system with multidirectional turning capability, through-the-tool coolant, proprietary chip control, and “Triple V” secure seating geometry. Dotson admitted he was not too concerned about the bells and whistles, as long as the tool would perform as well as what he was using already, and would save the company some money. He was pleased with the results.

“But, the Beyond Evolution inserts are dramatically less expensive,” he added for emphasis, “roughly 40% of what we were paying for our legacy tools. It was a clear win for us.”

How has business been for Dormer Pramet India in 2017? What about the key achievements and highlights during the year?

Triple time. The next win came on a job Dotson was running on one of EMC’s Daewoo Lynx 220 CNC lathes, a transmission gear shaft made of 1-1/4 in. (32 mm) 8620 steel, and using a 0.236-in. wide tool (6 mm) to back-turn a journal on the left side of the part, prior to cut-off. In this application, insert cost was still a concern, but Dotson’s primary goal was tool life improvement.

We spoke to Mr. Gautam K. Ahuja, Managing Director, Dormer Tools India Pvt. Ltd., to get details about the company’s overall performance over the last few years, market expansion and growth plans.

18581906093

18581906093