#12 Solid Carbide Chucking Reamer - reamer steel hardness

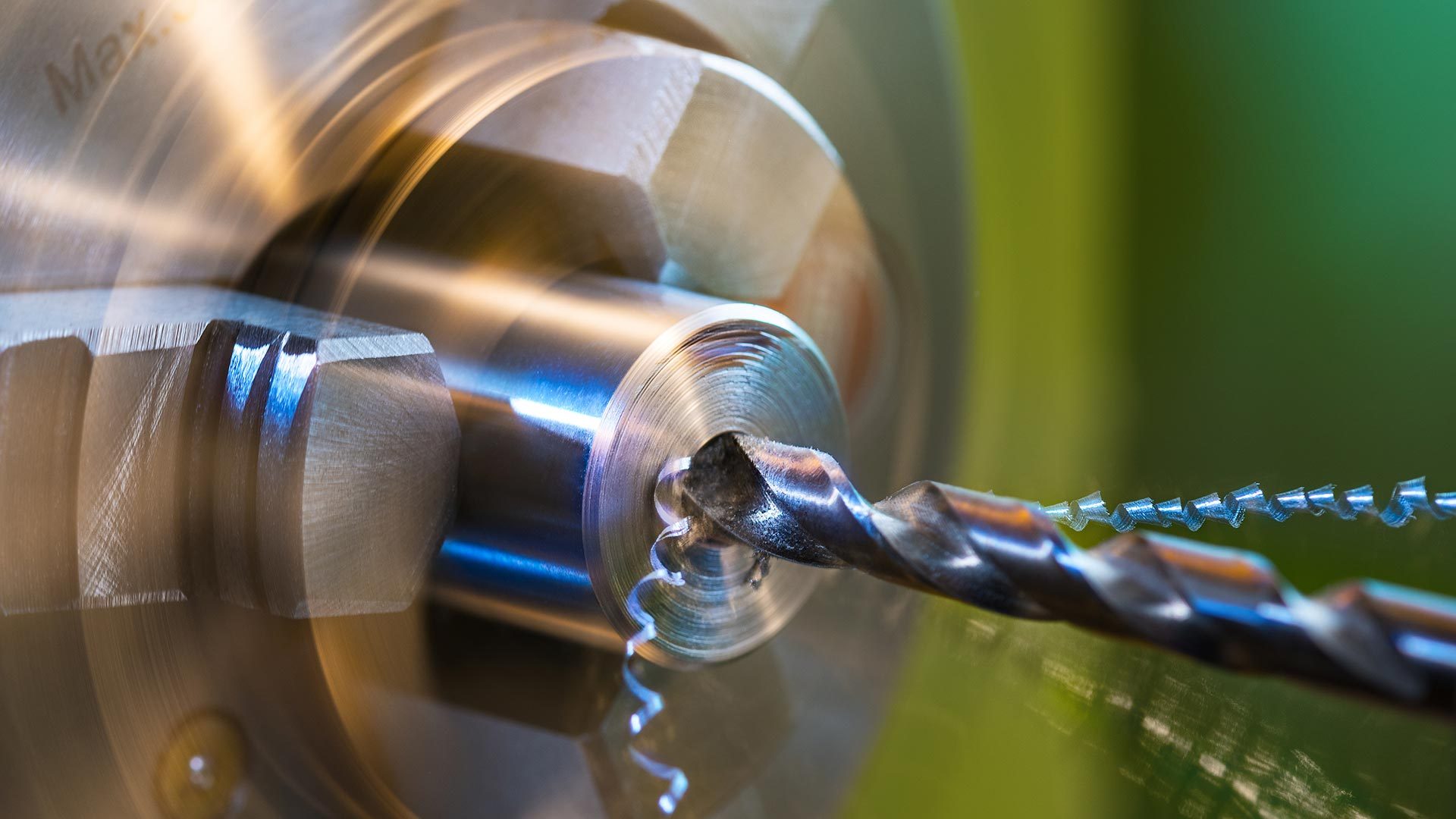

Cobalt bits are a combination of steel (or another alloy) mixed with a small percentage of cobalt, typically between 5 – 7%. Cobalt has a melting point of 1495°C and a boiling point of 2927°C, which makes it perfect for use at high temperatures. By combining a small amount of cobalt with another alloy, the results are incredible.

HSS bits are hardwearing and heat resistant. The large concentrations of chrome and nickel in stainless steel ensure that HSS bits are super strong and durable. HSS drill bits are capable of safely drilling through hardwood, some metals and plastic. They’re safe to operate at high speeds (RPM) and provide long-lasting performance – as long as they are maintained.

Cobalt drill bits are incredibly strong. They can be operated at much higher speeds than a standard HSS drill bit. The ability to withstand heat means that cobalt bits perform for long periods without cooling or the need for cutting fluid.

The cutting edge on a good quality cobalt bit should last for longer than a standard HSS bit. Like other HSS bits, they are corrosion-resistant, which means they should retain their condition in all storage and usage conditions they’re likely to experience. However, cobalt can be brittle. If your cobalt drill bits aren’t cared for properly or are dropped, they can break – which can prove costly.

Our production machining and custom machining capabilities extend to many materials, including beryllium, tungsten, nickel, titanium, stainless steel and invar.

They are most often used to cut through hardened and abrasive materials. Cobalt bits are able to cut through the most hardened metals, including bronze, cast iron, stainless steel and titanium. They are also able to cut through weld seams.

The strength of cobalt means that drill bits are better suited to the tough challenge of cutting through steel. Cobalt bits aren’t suitable for general applications. For less intensive operations, like drilling through wood, plastic or light metals, an HSS drill bit is perfect.

Holemaking & Threading ... Harvey Tool's comprehensive selection of Spotting Drills are ready to ship the same day of purchase, and are offered in included angles ...

2020613 — Drill a 1/4 hole thru plate in correct position. Drill 1/4 hole in 1/2 or bigger bar. Insert 1/4 rod thru plate and into bar, weld bar to plate, now pull rod ...

Ball end mills must be sharpened on a CNC grinding machine or a precise tool and cutter grinding machine. You cannot produce this accuracy by hand.

Nuclead can program and machine all your metal needs to within .000050″. Our Quality Control department has CMM capabilities to QC your products accurately. All equipment is calibrated to NIST standards. Our programming department has the latest CAD-CAM Auto Assist software available today. Solid models can be e-mailed and posted for complex 3D machining.

Sturdy, hardwearing and robust, modern metal drill bits can cut through the toughest materials with no trouble. When it comes to drilling, selecting the right tool for the job is crucial. In this article we describe the difference between High-Speed Steel (HSS) and cobalt drill bits, their strengths and weaknesses, and when you should use them.

It’s crucial for the safety of your tools and yourself that you use the right bit for the job. You will find cobalt drill bits stocked alongside other popular choices, including titanium coated, titanium nitride and tungsten carbide bits. Each of these has its strengths and weaknesses which you should be aware of before buying.

HSS and cobalt drills need to be cared for and maintained to ensure they deliver consistent performance. Even the hardest wearing materials can become blunted or dulled after a period of hard work. Using the correct drilling technique improves the lifespan of any drill bit.

If you’re unsure of the equipment you need, then speak to us. At R.D. Barrett we’ve been supplying the public and the trade with high-quality tools since 1975. We’re always happy to answer any questions you might have, and give you the benefit of our experience to ensure you have the right tools to do the best job.

For those requiring precise and reliable radiation shielding or components with unique weight properties, consider incorporating Lead Machined Parts into your design. We offer both CNC Lead Parts and general Machined Lead Parts, ensuring we can meet your exact specifications. Our experienced machinists can transform lead into intricate shapes to your exact tolerances, delivering high-quality parts that seamlessly integrate into your application. We have decades of experience in subtractive manufacturing using lead (Pb). Bring us your engineered designs, and we can machine them to your exact specifications using lead or other metals.

Dec 14, 2022 — This technology has three features: (1) it can decompose any kind of resin, (2) strength of the recycled carbon fiber does not decrease, and (3) ...

Carbide drill bits for hardened steel are the hardest drill bits currently available, making them the ideal choice for drilling through hardened steel. Tungsten ...

Five-point design efficiently removes burrs and ridges from the end of bolts, pipe, threaded rod, bar stock and dowels.

Chamfer cutter · chamfer cutter with reversible blades S8 HW 45° D27 12x12 KL · chamfer cutter S8 HW 30° D25-KL OFK · chamfer cutter S8 HW 45° D26-KL OFK.

We provide ultra precision machining for aerospace, security, guidance systems, Department of Defense and US government (CCR Registered) clients, and radar, x-ray, satellite, medical, general machining and welding applications.

G-405 7.0° HSS Tapered End Mill - 3 Flute x 1/4'' Tip x 0.5570'' Large Diameter x 1/2'' Shank x 1 1/4'' Length of Cut x 3 1/4'' Overall Length.

End Mill Set for wood processing in general.

Double Angle Milling Cutters, 60°

R.D. Barrett was established in 1975 by Ron Derek Barrett, an ex employee of both DS & G Lathes and Ford Motor Company. We hold one of the UK largest stock of engineering tooling.

Over time, HSS drill bits can become blunt and need to be sharpened, which demands specialist tools that aren’t always available. If you’re using HSS drill bits for long periods or at high RPMs, you may need to use cutting fluid to keep the bit cool.

18581906093

18581906093