01-26-64-023-BL - magnuson super charger

The reamer should have a left-hand spiral or a straight flute if it is to be used for through-holes. When using the left-hand spiral, the flute’s helix turns to the left, or in a counterclockwise direction. During the process of cutting, the reamer will force the chips to advance through the hole.

What is a reamertool used for

Reamer flutes are situated at the front of the device. Small chips are removed by passing along the reamer’s flutes. Flutes are classified into two types: straight and helical. Helix is further classified into four types: right hand, left hand, slow, and quick.

Chucking Reamer with Taper or Parallel Shank (Fluted) is another name for the tool that is often referred to as a machine reamer. The cutting blades of these sorts of reamers are short and parallel, and they have a beveled lead. The bodies of these reamers have large recesses between the shanks. Reamers often have cutting blades that are incorporated into a parallel or taper shank that is used for grasping the tool. The shanks can either be straight or taper, but the flutes themselves are invariably straight.

“Clark put his own head on the currency without any authority whatever,” declared an angry letter to the New York Times. Reporting by the Times depicted Clark's bearded portrait as an assault on the dignity of American money. Another letter-writer chimed in: “It shows the form of impudence in a way seldom attempted before. It is not the first time, however, that men have made a strike for fame, and only achieved notoriety.”

Minting new coins might not seem like a priority in a time of war. But without coinage, transactions of everyday life—buying bread, selling wares, sending mail—become almost impossible. One Philadelphia newspaper reported that the local economy had slowed to a crawl in 1863, citing that some storekeepers had to cut their prices “one to four cents on each transaction” or refuse to sell products outright because they were unable to get a hold of money.

Two months later, five-cent notes were quietly retired. And as Philadelphia's Daily Evening Bulletin reported in May of 1866, a new coin was to immediately take its place. “The President [Andrew Johnson] has approved a bill to authorize the coinage of five cent pieces, composed of nickel and copper,” said the article. “There are to be no more issues of fractional notes of a less denomination than ten cents.”

Reaming in shipbuilding, structural construction, and plate work can be accomplished with the use of a portable electric or pneumatic tool with a machine bridge reamer, as shown in figures (A) and (B). These are the sorts of reamers that have cutting blades that are parallel to one another. They also include a lengthy lead that is an integrated part of a tapered shank for gripping and driving the reamer. The flutes might be spiral or they could be straight. The reamer has a diameter that can range anywhere from 6.4 to 37 millimeters.

In the cutting process known as reaming, a specialized tool known as a reamer is used to widen an existing hole to a certain diameter while simultaneously creating a smooth finish on the walls of the hole. This is accomplished by the use of the reamer. A milling machine, a lathe, or drill presses are the common types of machines used for reaming. As a finishing operation, reaming is therefore performed. Before the hole can be reamed, it must first be roughed out using a different method, such as drilling. There are other ways to make holes with accurate sizes and a high quality finish on the walls, but reaming is frequently the best choice because of how quickly it can be done and how little it costs.

Reamers with numerous cutting edges typically have anywhere from four to six of these cutting blades. On the other hand, larger-diameter instruments can contain eight or even 12 blades. When there are more cutting edges, the rate of penetration will be higher, and the completed holes will have a tendency to be rounder. Additionally, more edges result in lower chip sizes. You do not want there to be a difficulty with chip evacuation because there are too many flutes. The vast majority of reamers are organized into size ranges, each of which has a certain number of teeth that corresponds to that size range.

There are several specialty carbide reamer possibilities. Chucking reamers, which generally have a straight shank and are used for general purpose reaming, automobile reamers, which are used for heavy-duty structural work, and repair reamers, which are widely used in utility and maintenance applications, are the most popular types of reamers.

The reamer’s material is determined by the workpiece material, however reamers may cut practically any metal. To attain exceedingly fine tolerances, the hole must be drilled, rough bored, and then ream. However, with aluminum, a reamer can occasionally remove material straight from a casting. A reamer is intended for precise hole tolerances rather than material removal. However, with aluminum, there are many cases where we can instantly run the reamer into the prefabricated hole and remove the material.

The taper reamer may either be driven by hand or by a machine. This features taper cutting edges for holes that fit pins with a taper of I in 50, and it has a parallel or taper shank for gripping and driving the reamer. The taper cutting edges are used to create holes that are compatible with pins. The flutes might be spiral or they could be straight.

In spite of the fact that spiral kinds have the potential to improve chip evacuation; the straight-flute reamer is the most cost-effective option. Spirals are more difficult to manufacture than other types of blades because the machine tools need an additional axis in order to grind the blade. As a result, we’ve come up with geometries for the straight flute that either assist shatter the chips or drive them ahead.

The reamer can be utilized in a drill press, turret lathe, or screw-cutting machine, depending on the application. It is operated at a modest pace, and the entire cutting process is completed while the flutes are in motion. The flutes travel at varying speeds and directions around the body of the reamer, which is round. Because of this, there is less of an inclination to babble. For work that requires greater precision, the use of a fluted reamer is recommended. Chucking reamers with a straight shank can have a diameter ranging from 0.5 to 32 millimeters, while those with a taper shank can have a diameter ranging from 5 to 32 millimeters.

A hand reamer is designed for manual reaming and usually has a handle. To compensate for the difficulties of beginning a hole by hand power along, it is built with a longer taper or lead in at the front than a machine reamer. It also allows the reamer to begin straight, lowering the chance of breakage.

When reaming blind holes, one must use extreme caution. It is imperative that careful thought be given to chip evacuation in order to avoid the chips marring the hole. It is best to never chop a chip more than once. This is the situation that occurs when a chip that has been cut becomes squeezed between the reamer and the hole, and the reamer pushes the chip between the finished hole and the reamer. This leads to a hole that is of low quality or possibly one that is out of tolerance altogether.

Machine reamers have a tiny lead in, and spiral flutes offer the benefit of automatically cleaning swarf. The reamer and the work piece are pre-aligned, eliminating the chance of the reamer deviating from its intended path. The machine’s steady force guarantees that the cutting begins quickly.

But in the spring of 1861, southern states began to secede, and Abraham Lincoln was sworn in as President. Soon shells were falling on Fort Sumter in Charleston, South Carolina. America was in crisis, and so was its currency. “The outcome of the Civil War was uncertain,” says Bowers, an author of several books on coin history. Widespread anxiety led to an important side-effect of war. “People started hoarding hard money, especially silver and gold.”

HandReamer

It turns out that even the name “nickel” is misleading. “Actually, nickels should be called 'coppers,'” says coin expert Q. David Bowers. Today's so-called nickels are 75 percent copper.

The cutting action is carried out entirely by the beveled edges at the very tip, which differentiates it from the fluted kind. The angle formed by the chamfered cutting edges is 45 degrees. The body, which is fluted, may be inserted into the reamed hole. In order to prevent the body from bending when it is inserted into the hole, it has a little taper and gets narrower towards the shank. A higher amount of metal may be removed with this style of reamer as opposed to using a fluted type.

This reamer might have a straight shank or a taper shank, and it could be operated by hand or by a machine. The reamers feature cutting edges that are tapered to fit a Morse taper, and they have shanks that are either parallel or tapered. The flutes might be spiral or they could be straight. It is possible to purchase the reamers in a package of three, which includes a roughing, a pre-finishing, and a finishing tool. There is a choice in terms of the diameter of the reamers for the finishing.

Coins seemed to vanish overnight, and the U.S. Mint couldn't keep up with demand. “The United States literally did not have the resources in gold and silver to produce enough money to meet the needs of the country,” says Douglas Mudd, the director of the American Numismatic Association. “Even the cent was disappearing.” In the South, this problem was even worse. The limited supply of gold and silver was needed to purchase supplies from abroad, which meant the Confederacy relied almost exclusively on paper currency.

One issue with reamers is preventing cutting edge chipping. The cutting edges are razor-sharp. Dropping them can damage the edge by leaving a burr or creating a negative cutting edge. This would have an impact on the way any tool cuts, but particularly reamers.

© 2024 Smithsonian Magazine Privacy Statement Cookie Policy Terms of Use Advertising Notice Your Privacy Rights Cookie Settings

Types of reamers pdf

© 2024 Smithsonian Magazine Privacy Statement Cookie Policy Terms of Use Advertising Notice Your Privacy Rights Cookie Settings

As far as the future of the nickel was concerned, the timing was perfect. The postwar economy began to gather steam again. “The supply was there, and the demand was there,” says Mudd. “People wanted coins.”

The most common type of reamer is the straight-flute variety. When using the straight flute, chips are not compelled to go in either direction. The arrangement of the coolant that pushes the chips has an effect on it. The chips are propelled forward by the radial coolant that runs via through-holes. When it comes to blind holes, having central coolant can assist in pushing the chips up and out of the hole.

The new coin was decorated with a shield, the words “In God We Trust,” and a large “5,” surrounded by a star and ray design. That year, the government minted a whopping 15 million five-cent nickels—more than 100 times the number of silver half-dimes minted the year before.

Left-hand spiral reamers have a propensity to push chips and coolant in front of the cut, allowing coolant to enter the hole and the reamer to exit. On tapered reamers, a left hand spiral can be employed to aid prevent grasping and binding. They should not be used in blind hole applications because the chips will pack at the bottom of the hole and prevent the reamer from cutting all the way to the bottom. There are four crucial criteria to consider when choosing a flute: flute diameter and length, pilot diameter and length, number of flutes, and flute depth.

Straight fluted reamers are utilized for a range of materials and applications in general. The length will be determined by the application. The entering end will be tapered somewhat. This causes the flute to self-center as it enters the hole, while the larger section of the flute will have a constant diameter to allow for the growth. Because right hand spiral reamers have a tendency to suck chips and coolant out of the hole, a right hand kind of helix should never be used on a tapered reamer; otherwise, the reamer may wedge, resulting in catastrophic tool failure.

What is a reamerused for in Dentistry

The shell reamer with an axial hole may be used on an arbor. It also features cutting edges that are almost parallel to one another and a sharpened bevel lead. These kinds of reamers are utilized for the finishing process of huge holes in order to preserve the tool. One arbor may accommodate a variety of different shell sizes when switched out. This results in a reduction in the cost of the solid shank for each individual instance. The shell reamer can either be of the rose chucking type or the fluted kind, depending on whether it is being used for finishing or truing the hole. The flutes might be spiral or they could be straight. The reamer can have a diameter ranging from 24 to 100 millimeters.

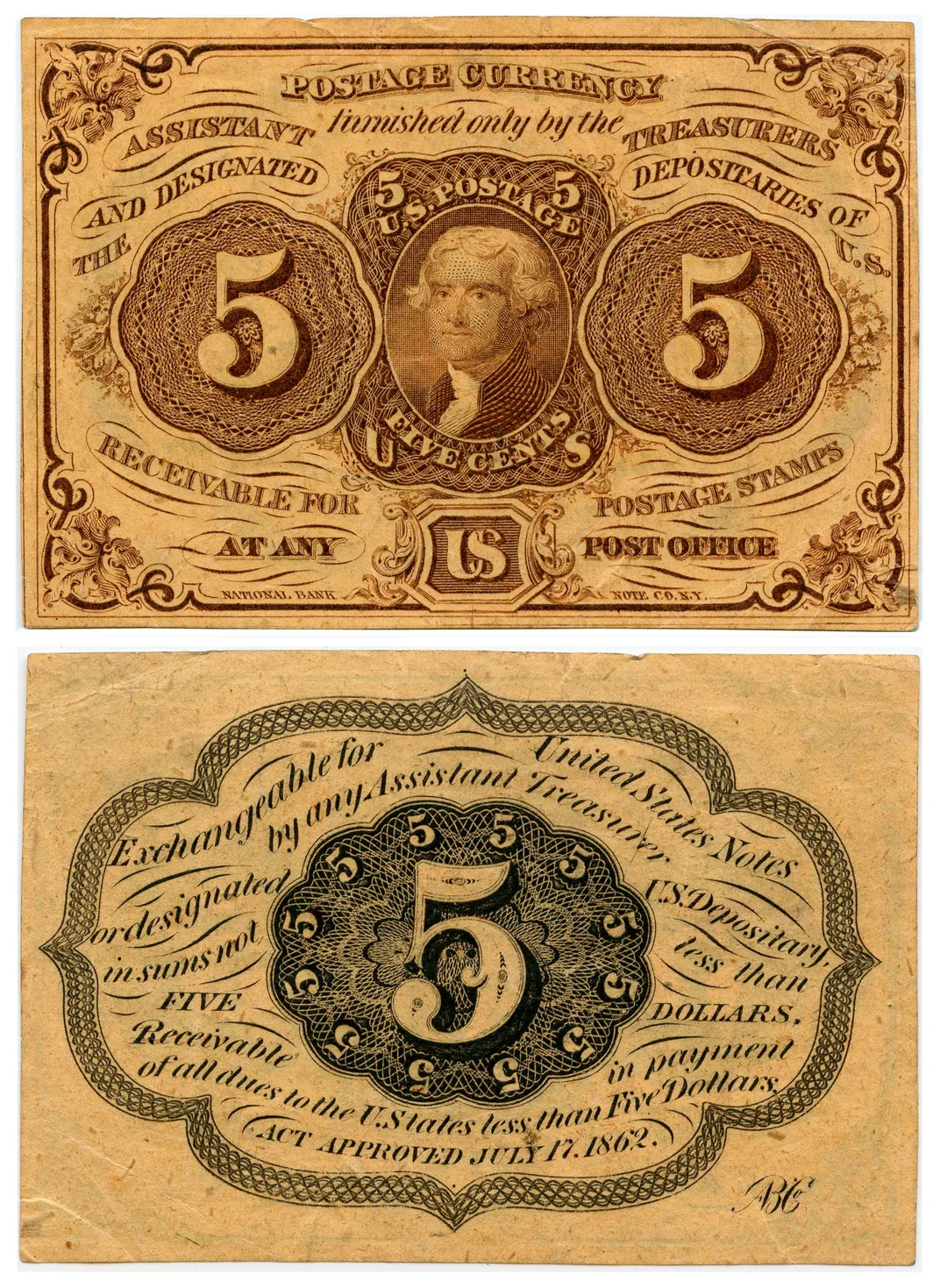

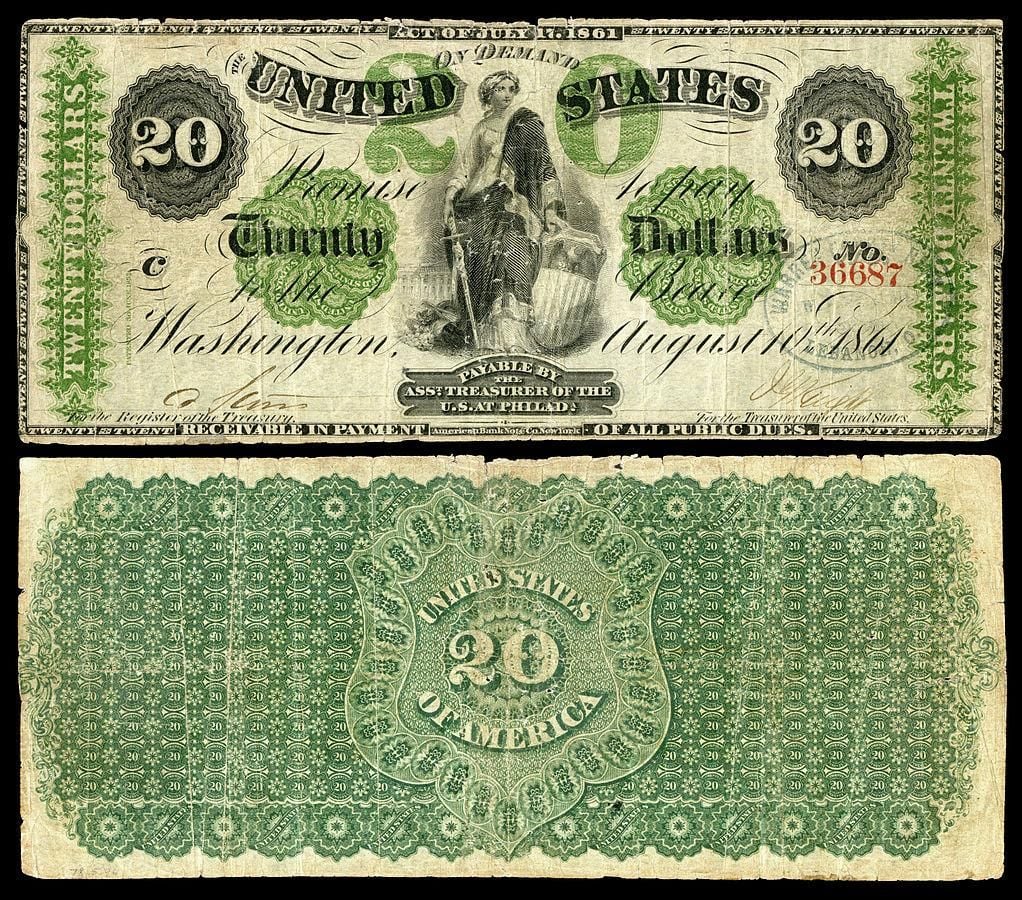

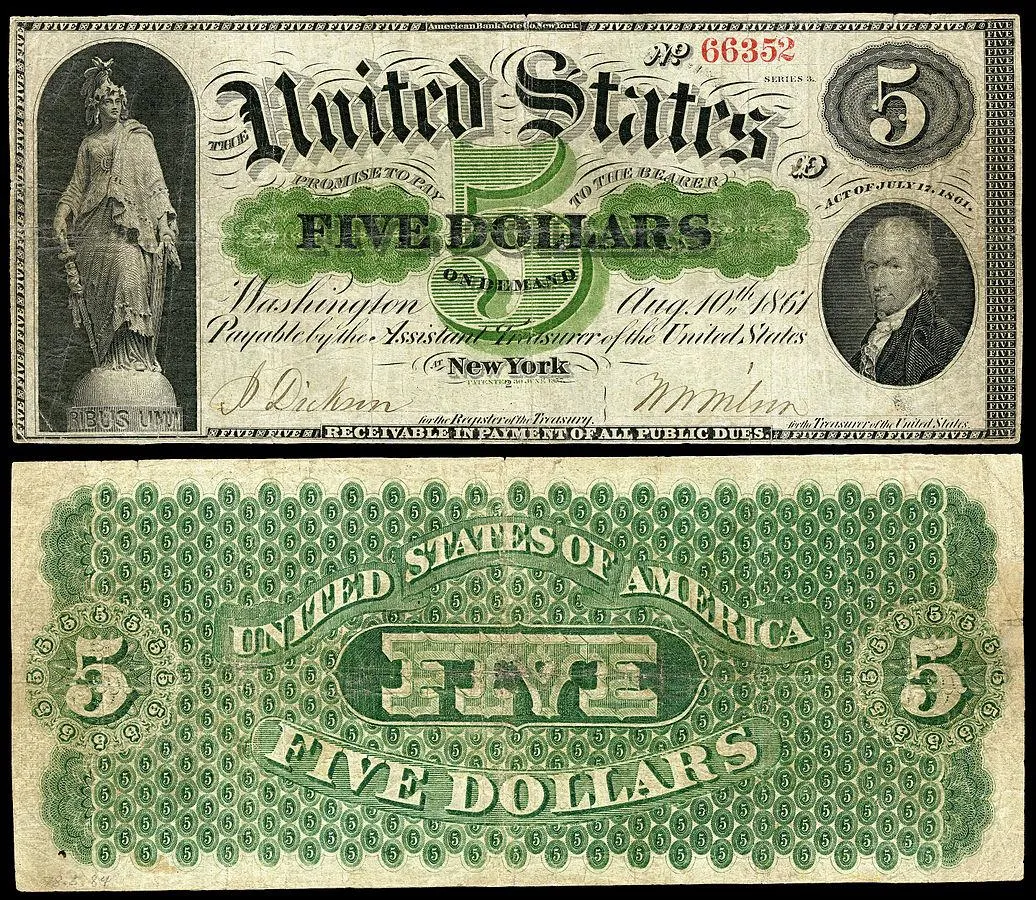

It was in this economic vacuum that the United States tried a series of monetary experiments. In 1861, the government began paying Union soldiers with “Demand Notes”—also known as “greenbacks.” Meanwhile, stamps were declared legal tender for small purchases; a round metal case was developed to keep them intact. “It looked like a coin with a window on it,” says Mudd.

While legislators were making speeches in Congress denouncing Clark's portrait, an industrialist named Joseph Wharton was busy prodding legislators to find an alternative to paper money. In the early years of the war, Wharton had bought up nickel mines in New Jersey and Pennsylvania, so his suggestion should come as no surprise. He wanted coins to be made out of nickel.

Carbide reamers are specifically engineered to increase the diameter of an existing hole while maintaining a high level of precision, consistency, and predictability throughout the process.

As the United States turned its attention to rebuilding, not all metals were scarce. War production had expanded America's industrial capacity, and nickel was available in huge quantities. The advantage of nickel lay in what it wasn't. It wasn't scarce, which meant the government could print millions of coins without creating new shortages. And it wasn't a precious metal, so people wouldn't hoard it.

In fact, some cent coins had already been minted using nickel—and as one Pennsylvania newspaper pointed out, “the hoarding of them is unwise and injudicious.” There's no sense in hoarding a coin whose value comes from a government guarantee.

The general conditions for using reamers and the results they produce might vary greatly depending on the state of the material, the configuration of the tool, and the equipment. The correct execution of reaming, on the other hand, calls for thorough planning and close attention to detail. Important considerations include the speeds and feeds of the drill as well as the quantity of stock that should be left over after drilling and choosing the appropriate reamer for the task. In most cases, reamers are only designed to cut away between 2% and 3% of the target size.

Nickels have come full-circle since their roots in the gold and silver shortages of the Civil War. One hundred and fifty years ago, coins made of nickel seemed convenient because they were made of cheap metals. These days, nickel and copper prices are high, and our beloved 5-cent coin costs around 8 cents to produce. Maybe it's time to bring back the five-cent note.

Cutting edges on reamers are inherently more delicate than those on other cutting instruments, but they are also more important. All cutting edges are fragile, but protecting all reamer edges is important because if you damage even one, it will compromise your size and surface polish. If your cutting edge is chipped, one of those teeth is creating a void within that portion while it is in that cut.

Those aren't the only surprises hidden in the history of the nickel. The story of America's five-cent coin is, strangely enough, a war story. And 150 years since it was first minted in 1866, the modest nickel serves as a window into the symbolic and practical importance of coinage itself.

The geometry of the reamer changes depending on whether the flutes are spiraled to the left or the right, or if they are straight. When it comes to clearing chips, spiral flutes are superior to straight flutes; nevertheless, straight flutes may also be used because the number of chips produced during the reaming process is little.

Machinereamer

If you need to maintain hole diameter tolerances that are more stringent than +/- 0.002 inches, using a reamer is definitely the best option for you. For instance, you might figure out the desired hole size by using our Press Fit Calculator, and then you could use a reamer to get that hole size while staying within the tolerances. The material of the workpiece has an effect on the surface finish that is produced by reaming. The range for steels is 30 to 60 rms, but the range for cast iron is 50 to 80 rms. Aluminum may be given a finish that is as fine as 8 rms by using a PCD reamer.

ChuckingReamer

Mudd puts the problem in more familiar terms. “It's like, all of a sudden, not being able to go to 7-Eleven because [the cashier] can't make change,” he says. “And if [they] can't make change, the economy stops.”

When working with some substances, you should avoid using a left-hand spiral. Cast iron and some aluminum alloys are examples of these types of materials. Because a spiral flute does not shear the material as well as a straight flute does, it is possible that the spiral will smear the silicon that is present in the aluminum, for instance, when working with high-silicon aluminum..

That’s all for now, and thanks for reading. If you like our story, please tell your friends about it. If you have any inquiries or want to order carbide reamers, please contact HUANA..

So, we hope that we have dispelled all of your concerns regarding Carbide Reamers. HUANA carbide reamers are intended for a wide range of reaming applications and materials, including titanium, super alloys, hardened steels, stainless steels, steels, cast iron, graphite, brass & copper, composites, plastics, and wood.

SocketReamer

In the 20th century, one other shift cemented the nickel as an indispensable coin of the realm: the rise of coin-operated machines. Nickels were the ideal denomination for vending machines, jukeboxes, and slot machines. It also cost five cents to attend a “nickelodeon”—that is, a nickel theater. (Odeon comes from the Greek word for theater.) “Nickels went into the mainstream,” says Bowers.

Reamer

A shank is the reamer’s shaft or stem. It’s just next to the flute. When choosing a shank, four major factors must be considered: diameter, type, hardness, and one or two piece construction.

This reamer has parallel cutting blades that have a taper and a bevel lead integrated with a shank that is the nominal diameter of the cutting edges, and the end of the reamer has a square. The flutes might be spiral or they could be straight. The hand reamer has a square tang, and it is designed to be operated with the hand in order to correctly size the holes. The reamers’ primary objective is to remove the least amount of metal possible between 0.05 and 0.125 millimeters. Because it needs to be easy to start, it has a modest taper towards the end over a distance that is equivalent to its diameter.

High speed steel is the most widely utilized material since it is reasonably affordable and works effectively on a wide range of materials. However, many other materials, such as carbide and high cobalt alloy steel, are utilized to create reamers. Carbide is more costly than high speed steel, but when reaming steel, it outlasts it by a factor of ten. The most costly alternative for reaming titanium and stainless steel is high cobalt alloy steel. The cutting fluid that must be used to extend the life of the reamer is determined by the material of the workpiece. Aluminum, brass, stainless steel, and mild steel may all be treated with soluble oil. When reaming cast iron, cold air can be utilized, and synthetic oil can be used with aluminum and plastics.

The nickel caught on for a few reasons. First of all, after years of coin shortages, nickels flooded the economy. Nearly 30 million were printed in 1867 and 1868. “The nickel was the coin from 1866 to 1876,” says Bowers. Even after that, as dimes and quarters rose in prominence, nickels were the coin of convenience. Bottles of Coca-Cola, which entered the marketplace in 1886, cost a nickel for 73 years.

The nickel wasn't always worth five cents. In 1865, the U.S. nickel was a three-cent coin. Before that, “nickel cents” referred to alloy pennies.

The shield nickel was produced until 1883, when it was replaced due to manufacturing issues by the “Liberty Head” nickel. The decades that followed saw a succession of new designs, starting in 1913 with the Buffalo nickel and followed in 1938 by the initial Jefferson nickel. (Ironically, during World War II, nickel was so essential for war production that nickels were produced without any nickel.) The most recent update, in 2006, revised Jefferson's image from a profile to a frontal portrait.

Reamers with straight flutes or right-hand spirals are the ones that are recommended for use while drilling blind holes. When using the right-hand spiral, the helix of the flute will move in the right direction, which is clockwise. In order for the reamer to be able to reach the bottom of the hole, it pushes the chip back up through the cut and out the top of the hole.

A reamer is a tool that is used to enlarge or finish holes that have been pre-drilled, bored, or cored in order to provide a high-quality finish and an accurate size. A reamer is a multi-tooth cutter that is used to cut through comparatively little material at once. There are several categories of reamers, each of which is distinguished from the others by the operation, the function, and the form.

A machine jig reamer has cutting edges that are short and parallel, and they have a bevel lead. Additionally, there is a guide between the shank and the cutting blades, and it is integrated with a tapered shank that is used for gripping and driving. The flutes are shaped like helicoids. The reamer can be properly located thanks to the plain portion of the body, which slides into a bushing on the jig. The reamer can have a diameter anywhere from 7 to 50 millimeters.

To understand how the nickel got its name, you have to go back to an era when precious metals reigned supreme. In the 1850s, coins of any real value were made of gold and silver. In the event of a financial crisis—or worse, the collapse of a government—precious metal coins could always be melted down. They had intrinsic value.

Only after a bizarre 1866 controversy about paper money, however, did nickel coins finally conquer everyday life. At the time, the National Currency Bureau (later called the Bureau of Engraving and Printing) was led by a man named Spencer Clark. He was tasked with finding a suitable portrait for the five-cent note. Clark's selection was a proud-looking man with dark eyes and a thick white beard. The public was not amused.

For the duration of the war, the American economy puttered along with all kinds of competing currency. Even private banks and businesses were releasing their own notes and coins. Shopkeepers could give coins, stamps or bills as change. The war finally ended in 1865, but it took many months for precious metals to trickle back into circulation. “It's not until after the Civil War that coin production resumes at full capacity,” says Mudd.

18581906093

18581906093