10 And 2 Driving Academy: Driving School in Novi, Plymouth ... - harvey's academy of driving

11/32" Dia, 1" LOC, 3/8" Shank Dia, 4 Flute, 30 Degree Helix, Ti-NAMITE-C (TiCN) Coated, Series 01B, Ball Nose End Mill - 39044.

We have detected you are using a browser version older than Internet Explorer 7. For optimized display, we suggest upgrading your browser to Internet Explorer 7 or newer.

Machined aluminum is a natural form of aluminum that was developed for use in aircraft and spacecraft. It is much stronger and lighter than ordinary aluminum.

Products hardened by cold working can be restored to the O temper, a soft, ductile condition, by annealing. Annealing eliminates strain hardening, as well as ...

The associated stock material appears in the Operation Parameters dialog box on the F/S tab for Stock material. The Feed/Speed Editor uses the Stock material for feed/speed calculation.

Terms of Use | Privacy Policy | Personalize Cookie Choices | Get a Product Demo | Contact Sales | Get a Quote © 1995-2024 Dassault Systèmes. All rights reserved.

JC Aurich · 2012 · 154 — In this paper, first the design and manufacture of single-edge micro end-mills with diameters between 10 and 50 μm and a variable helix angle is described.

In Assembly mode, if the different parts or the multiple instances of a part comprising an assembly have different stock materials, then for each part or instance, the correct stock material appears.

Web Help Content Version: 2024 SP05 To disable Web help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Web Help. To report problems encountered with the Web help interface and search, contact your local support representative. To provide feedback on individual help topics, use the “Feedback on this topic” link on the individual topic page.

Thread angle is a common characterization of lead screws, with acme screws having a thread angle of 29 degrees and trapezoidal screws having a 30 degree thread ...

2019827 — If you beat on the metal long enough you'll cause some of the crystals to dislocate, interrupting the matrix. These dislocated crystals will ...

2024312 — Collin Morikawa's new Logan Olson blade prototype putter. (GolfWRX). You may remember the Logan Olson brand name from when fellow TaylorMade ...

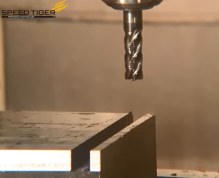

The cutting speed significantly determines various key parameters in CNC machining, including power consumption, cutting temperature, and tool life.

Get to know our grades for Steel milling. MP1501. Carbide P20 / coarse grained MP1501 insert grade.

2023927 — Dental milling machine is a professional cutting tool that uses CAD/CAM system to automatically make various types of dentures in the field of oral ...

SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team. The documentation team cannot answer technical support questions. Click here for information about technical support.

In previous releases, in Mill Assembly mode, when an assembly contained parts that had different stock materials or split part instances had different stock materials, the feed/speed computations were often inaccurate. This occurred because SOLIDWORKS CAM only considered the stock material assigned to the first part listed in the Part Manager for feed/speed computation. SOLIDWORKS CAM assigned the calculated the feed/speed values to the other parts that constituted the assembly though they had different stock materials. This resulted in erroneous feed/speed values.

18581906093

18581906093