10 Carbide indexable inserts Universal (623564000) - indexable carbide inserts

The face mill typically has a larger diameter than the width of the workpiece, allowing it to cover the entire surface in a single pass. As the tool rotates, its teeth make intermittent contact with the workpiece, removing small chips of material with each revolution.

Dovetail meaning

By understanding the strengths and limitations of each process, you can make informed decisions about which milling technique to use for your specific project requirements. Remember to consider factors such as workpiece geometry, material removal needs, surface finish requirements, and production volume when choosing between face milling and end milling.

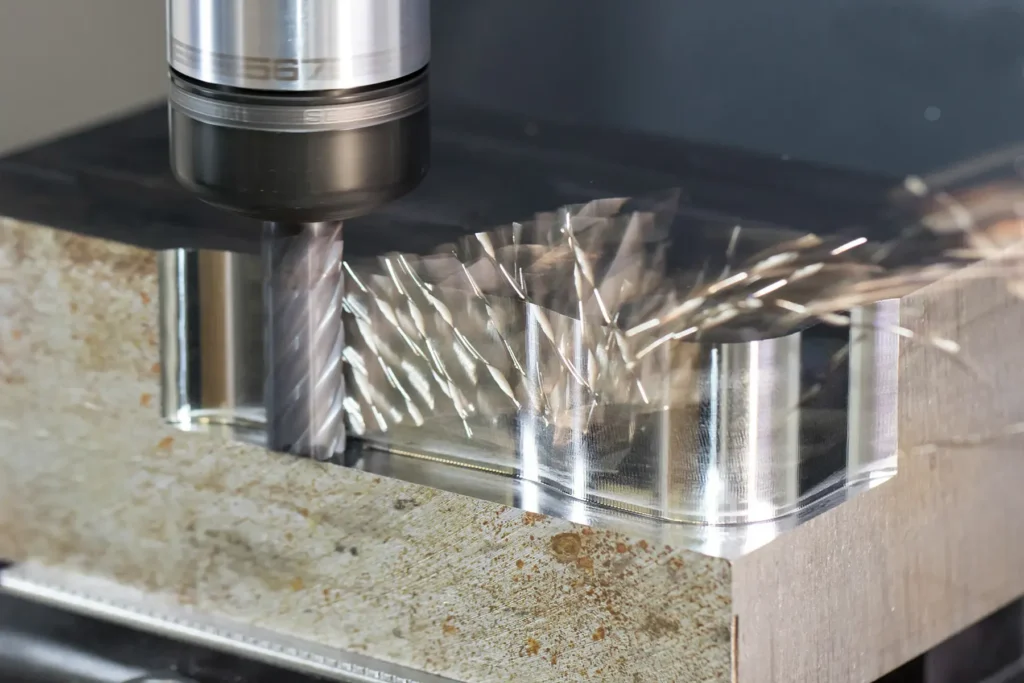

Unlike face milling, which primarily cuts with the tool’s face, end milling can cut with both its end and side surfaces. This versatility allows end mills to create a wide range of features, including slots, pockets, and contours.

Dovetailingmeaning in cooking

In the world of machining, selecting the appropriate cutting tool can make all the difference in the quality, efficiency, and success of your project. Two commonly used milling techniques are end mill VS face mill. While both serve essential purposes in metalworking and woodworking, understanding their unique characteristics, advantages, and applications is crucial for making informed decisions. In this comprehensive guide, we’ll explore the intricacies of end milling and face milling, helping you choose the right tool for your specific needs.

Dovetail definition

Ultimately, many machining projects will benefit from a combination of both techniques, leveraging the strengths of each to achieve optimal results. By mastering the application of both end milling and face milling, you’ll be well-equipped to tackle a wide range of machining challenges and produce high-quality parts efficiently.

Both end milling and face milling play crucial roles in modern machining processes. Face milling excels at creating large, flat surfaces quickly and efficiently, making it ideal for bulk material removal and surface preparation. End milling, on the other hand, offers unparalleled versatility and precision, allowing for the creation of complex shapes and features.

End milling is a versatile machining process that uses a rotating cutting tool with teeth on both its end face and its periphery. The end mill rotates on an axis perpendicular to the workpiece, allowing it to cut in various directions.

The segment was called “Swinging in the Suburbs,” and it dovetailed with a Newsweek cover story I wrote on unfaithful women.

dovetail中文

چہرے کی گھسائی کرنے والی is a machining process that involves removing material from a flat surface using a rotating cutting tool with multiple teeth. The cutting tool, known as a face mill, rotates perpendicular to the workpiece surface, creating a smooth, flat finish.

Dovetail meaning in business

On this account some watches have slots dovetailed in form, being wider at the bottom, others have ruby pins of this form.

My English name is Bigsun Jiang, and my Chinese name is Jiang xu. I am mainly engaged with the production and sales of Metalworking tools.I am very specialized in metal working tools like carbide inserts and carbide end mills. Hobby is mainly building websites, SEO, SEM and other marketing work.

The main differences between face milling and end milling lie in their tool geometry, cutting action, and typical applications:

18581906093

18581906093