10-32 unc roll tap academy tool kit 5945352 - roll tap

YY Na · 2021 · 6 — Is Your Chatbot Perplexing?: Confident Personalized Conversational Agent for Consistent Chit-Chat Dialogue. 1229. Page 5. Table 1: Automatic evaluation of the ...

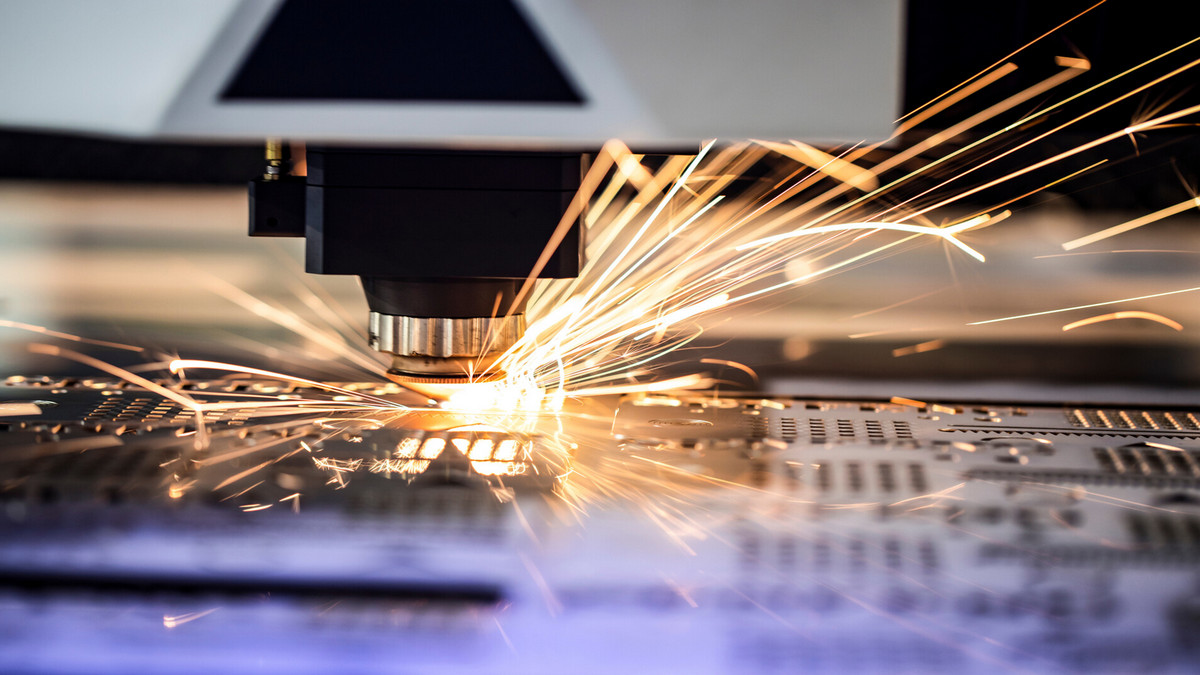

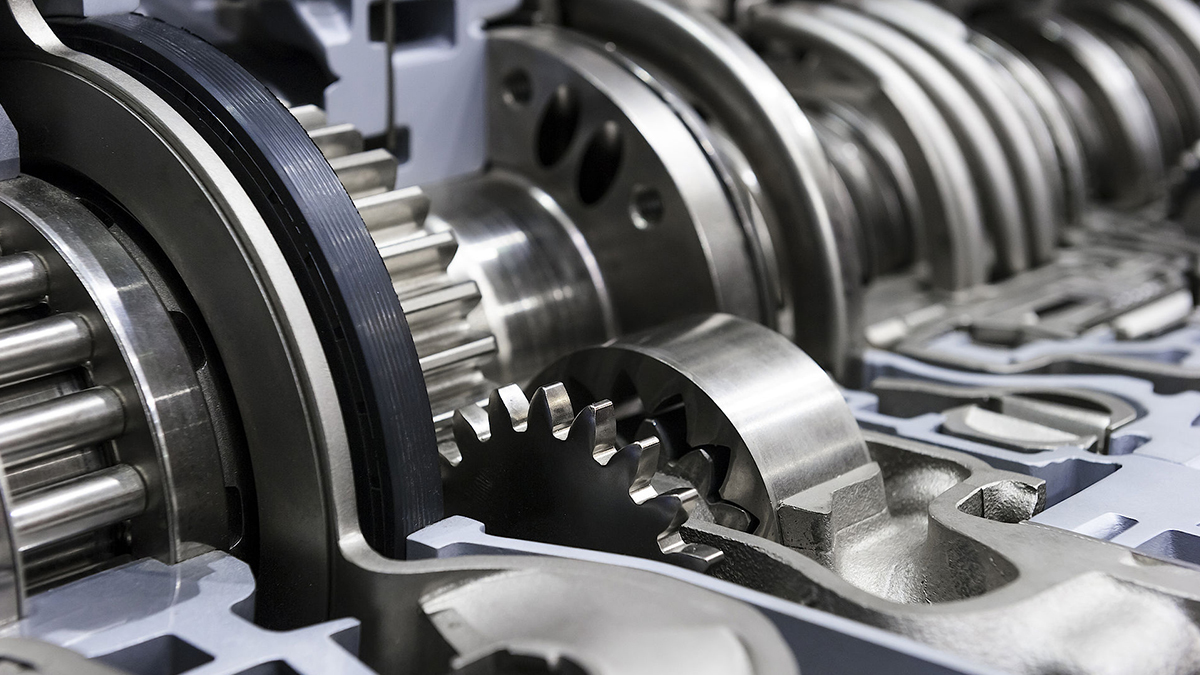

Machine tools can be divided into two categories: metal cutting machine tools and metal forming machine tools according to their functions. Metal cutting machine tools covers machining machines, drilling machines, milling machines, grinding machines, planning machines, electric discharge machines, etc.; metal forming machine tools covers lathes, boring machines, punching machines, etc.

Msc carbideinserts

A grinding machine (grinder) is a tool machine that uses abrasive tools to grind the surface of a workpiece. Most grinding machines use high-speed rotating grinding wheels for grinding, and a few uses of other abrasive tools such as oilstones, abrasive belts, and free abrasives for processing, such as honing machines, ultra-finishing tool machines, belt grinders, and grinding machines. polishing machine, etc.

The boring machine mainly uses the boring tool to boring the existing prefabricated holes of the workpiece. Usually, the rotation of the boring tool is the main motion, and the movement of the boring tool or the workpiece is the feed motion. It is mainly used for machining high-precision holes or finishing multiple holes at one time, and can also be engaged in the machining of other machining surfaces related to hole finishing. Using different tools and accessories can also be used for drilling, milling, and cutting. Its machining accuracy and surface quality are higher than those of a drilling machine. The boring machine is the main equipment for processing large parts.

A lathe is a machine tool that mainly uses a turning tool to turn a rotating workpiece. On the lathe, drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing.

TurningInserts

Authorized DP Technology ESPRIT CAD/CAM Distributor located in Houston, Texas. Shaping the Future of Manufacturing.

High Speed Steel Saws · Jeweler's Slotting Saws · Well Screen Slotting Blades · Screw Slotting Saws · Plain Metal Slitting Saws · Metal Slitting Saws with Side Teeth ...

These Garant German Milling Inserts for Softcut 45 High-Performance Indexable Face Mill offer increased insert thickness for the highest metal removal rates and are protected against wear by their coating.

Metalworking machines from OPTIMUM Maschinen GmbH - machines with a high quality standard!

ToolInserts

Tap and Drill Size Chart ; 1″-8 .8750, 7/8 ; Fine Thread ; 0-80 .0469, 3/64 ; 1-72 .0595, No. 53.

CarbideInserts

A milling machine refers to a machine tool that mainly uses a milling cutter to process various surfaces on a workpiece. Usually, the rotation of the milling cutter is the main movement, and the movement of the workpiece (and) the milling cutter is the feed movement. It can process planes, grooves, and various curved surfaces, gears, etc. A milling machine is a machine tool that uses a milling cutter to mill a workpiece. In addition to milling planes, grooves, gear teeth, threads and spline shafts, milling machines can also process more complex profiles, with higher efficiency than planers, and are widely used in machinery manufacturing and repair departments.

Knuth CNC Drill Press/Milling Machine Mark Super CNC.

Millinginsert types

2024626 — The Ultimate Guide to Titanium CNC Machining Titanium CNC machining is one of the most common machining methods. That's because titanium is ...

Drilling machine refers to a machine tool that mainly uses a drill to machine holes in a workpiece. Usually, the rotation of the drill bit is the main movement, and the axial movement of the drill bit is the feed movement. The drilling machine has a simple structure and relatively low machining accuracy. It can drill through holes and blind holes, replace special tools, expand, drill holes, ream holes or perform tapping and other processing. During the machining process, the workpiece does not move, the tool is moved, the center of the tool is aligned with the center of the hole, and the tool is rotated (main motion). The feature of the drilling machine is that the workpiece is fixed and the tool rotates.

LatheInserts

A planning machine (planer) is a linear motion machine tool that uses a planer to plan the plane, groove or forming surface of a workpiece. Using planer processing, the tool is simpler, but the productivity is low (except for processing long and narrow planes), so it is mainly used for single-piece, small batch production and machine repair workshops, and is often replaced by milling machines in mass production.

In Year 3, you'll build your first race car with final year students and represent NUS and Singapore at FSAE Michigan in June. ... ©2024 by NUS Formula SAE.

2020430 — Chatter is the unwanted noise during machining due to friction between tool and the workpiece. This is due to less sharpness of the tool. That's ...

A punching machine (punch) is a punching press. In production, the stamping process saves materials and energy compared with traditional machining, has high efficiency, does not require high technical requirements for operators, and can make products that cannot be achieved by machining through various mold applications. are more and more widely used.

We use cookies to optimize and continuously update it according to your needs.The settings can be changed at any time under "Privacy"

Masonry and concrete nails: Made from hardened steel, concrete nails have fluted shafts. Masonry nails have grooved shafts that can cling to concrete or brick.

WARNING: This product can expose you to Cobalt and Nickel which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov

18581906093

18581906093