10pcsM2.0h.6x4xd2.85xt6 torx Screws for Carbide Inserts ... - hitachi milling insert

As a local machine shop and manufacturer of high-end machined components and engineering solutions, we are proud to have earned our reputation. Our dedicated team of production specialists, designers, engineers, and creatives works by a set of core values.

Manufacturers who have implemented the system primarily use a zero-point workholding as a quick way to securely and precisely load, unload and locate workpieces on a machine table. It’s proven especially for part access and automated 5-axis machining. The versatile workholding system has also been effectively used in grinding, turning, welding, EDM, inspection and assembly.

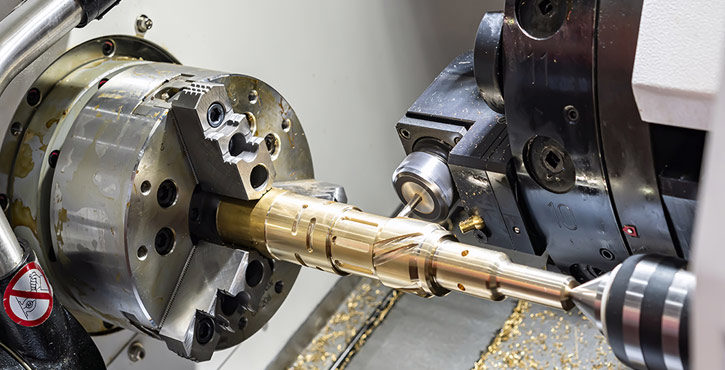

4 Flutes Machining offers high-end precision CNC machining services by working as a team to provide you with the right engineering solutions.

Our focus lies in manufacturing high-end machined components and engineering solutions for everything from automotive to medical — focused on your specific needs. We take your idea from design to production, and manage all functions related to prototype, manufacturing, and delivery.

Our multi-axis workholding products are designed to provide flexibility and functionality for 5-axis machining and 5-sided machining via multiple-part transfers. We also offer solutions for machines with retrofit 4th/5th axis tables. BIG DAISHOWA can help you to maximize the benefits of your machine design through efficient workholding. These CNC workholding fixtures locate and stabilize the workpieces without obstructing access to the top and sides of the part. They also allow a clamped workpiece to be flipped into new orientations for subsequent machining operations without unclamping it from the workholding.

We assist with product, account and procedure questions. We design tool set-ups, schedule service calls and help our customers receive the maximum efficiency from our tooling.

At 4 Flutes Machining, our attention to detail drives our direction. Through high-end prototype work, we provide short- to medium-run production for smaller quantities.

4 Flutes Machining is a locally-owned company located in Vicksburg, Michigan that promises precision, timeliness, and excellence from the initial conversation to the final product. We desire to turn your idea into reality and will work with you every step of the way.

Every job or situation will be a little different, but choosing the correct workholding device or system for the work you do should be guided by four factors:

If you’re looking for state-of-the-art prototype parts and flawless production work, 4 Flutes Machining has you covered. We use many different inspection and measurement tools to ensure the highest quality machining that reaches our customers’ specifications.

Here, Jeffrey Mosher speaks with Zack Bishop, President, of 4 Flutes Machining, Vicksburg, MI, a 2024 APEX Accelerator Best Small Business Awardee winner for this year's cycle of Michigan Celebrates Small Business. Michigan Celebrates Small Business is marking its twentieth year.

In a lead-up to the 2024 Michigan Celebrates Small Business Gala Celebration, Jeffrey Mosher spoke with several winning companies from this cycle. This year’s gala took place at the Breslin Center in East Lansing, MI, on May 21st! For more details please visit michigancelebrates.org/.

18581906093

18581906093