Insert Coating Makes the Grade in Progress Initiative - cnc lathe cutting tool insert

Browse key industry insights spread across 200 pages with 110 Market data tables and figures & charts from the report on the "Global Tungsten Carbide Market Size, Share, and COVID-19 Impact Analysis, By Application (Cemented Carbide, Coatings, Alloys, and Others), By End User (Aerospace & Defence, Automotive, Mining, and Construction, Electronics, and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 – 2033."

June 27, 2024 14:00 ET | Source: SPHERICAL INSIGHTS LLP SPHERICAL INSIGHTS LLP

The μ-precise solid carbide milling cutter cutters have a stable core geometry and an optimised flute profile. Both reduce displacement during milling and ensure stability which is reflected in a very high contour accuracy. This makes the tools suitable for finishing high-precision fits and guides with exact angular accuracy.

Global Aerogel Insulation Market Size, Share, and COVID-19 Impact Analysis, By Type (Silica, Polymer, Carbon, and Others), By Form (Blanket, Particle, Panel, Monolith), By Application (Oil and Gas, Construction, Transportation, Performance Coating, Daylighting & LVHS, and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 – 2032

Every milling application covered With its new G-Mold μ tool range, Gühring can now cover all milling processes in mould making. The solid carbide full-radius milling cutter “G-Mold μ65 B” and the high-precision torus cutter “G-Mold μ65 T” are perfect for copy milling and finishing of moulds and mould inserts made of hardened steel up to 65 HRC. The cylindrical high-precision finishing cutters “G-Mold μ65 F” for hardened workpieces and “G-Mold μ48 F” for soft workpieces enable the optimal angular accuracy and exact fits when finishing guides and pockets in moulding plates.

Global Carpet Tape Market Size, Share, and COVID-19 Impact Analysis, By Adhesive Type (Rubber-based Carpet Tape and Acrylic-based Carpet Tape), By Application (Carpet Installation, Rug Binding, Temporary Floor Covering, and Others), By End-Users (Residential and Commercial), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 – 2033

North America is anticipated to grow fastest in the global tungsten carbide market during the projected timeframe. A wide range of variables are propelling the region's explosive expansion. due to the growing automotive, aerospace, and electronics industries in North America, as well as the need for wear-resistant parts and significant performance components, tungsten carbide is in high demand. The tungsten carbide market is driven by research and development, technological developments, and the acceptance of complex materials, all of which are highly valued in this region. The growing electric vehicle, renewable energy, and additive manufacturing sectors in North America also depend on tungsten carbide.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

Inquire Before Buying This Research Report: https://www.sphericalinsights.com/inquiry-before-buying/4704

Global Sustainable Aluminum Market Size, Share, and COVID-19 Impact Analysis, By Product (Sheet, Plate, Cast Products, Extrusion, and Others), By Processing Method (Rolling, Extruding, Casting, Forging, Drawn, and Others), By End-Use (Construction, Transportation (Aerospace, Automotive, and Marine), Packaging (Food & Beverages, Cosmetics, and Others), Electrical, Consumer Durables, Machinery & Equipment, and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 – 2033

Global PFAS Filtration Market Size, Share, and COVID-19 Impact Analysis, By Technology (Reverse Osmosis, Ion Exchange Resins, Granular Activated Carbon Filters, and Others), By End-User (Commercial, Industrial, Municipal, and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 – 2033

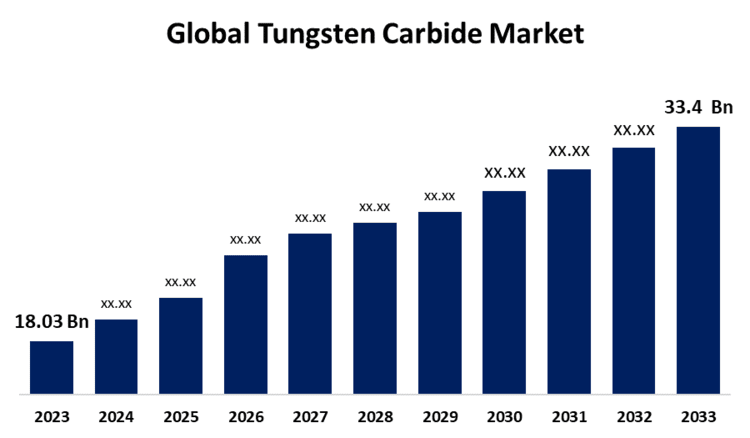

New York, United States , June 27, 2024 (GLOBE NEWSWIRE) -- The Global Tungsten Carbide Market Size is to Grow from USD 18.03 Billion in 2023 to USD 33.4 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 6.36% during the projected period.

Market SegmentThis study forecasts revenue at global, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the Global Tungsten Carbide Market based on the below-mentioned segments:

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

The automotive segment anticipated for the largest revenue share of the global tungsten carbide market during the projected timeframe.Based on the end users, the global tungsten carbide market is divided into aerospace & defense, automotive, mining, and construction, electronics, and others. Among these, the automotive segment anticipated for the largest revenue share of the global tungsten carbide market during the projected timeframe. Due to the growing need for innovation and flexibility in the creation and production of new machinery, the automotive sector currently controls the majority of the market.

For further details contact Gühring South Africa on TEL: 041 372 2047/46/43/38 or visit www.guhring.co.za

The new range offers a high degree of flexibility with over 350 different dimensions, a wide range of full or corner radii as well as corner chamfers and different versions for hard and soft materials. Because quality counts above all in addition to quantity, the tool manufacturer has invested specifically in specialised production and measuring technologies at its site in Germany – for tools that customers in tool and mould making can rely on.

Asia Pacific is expected to hold the largest share of the global tungsten carbide market over the forecast period. Asia Pacific has surpassed all other areas to become the leading force in the global market for tungsten carbide. Other elements add to the region's importance. Large manufacturing sectors are present in the Asia Pacific area, with South Korea, China, Japan, and India at the forefront. These industries include mining, autos, and electronics. Due to the increased infrastructure, quick industrialization, and expanding customer base, tungsten carbide is highly sought after in a variety of industries. In response to the central government's goal for infrastructure investment as a means of promoting economic growth, China's construction industry grew quickly. As part of their smart city’s initiative, 99 Indian cities have requested investments totalling USD 31,650 billion. It is anticipated that 500 towns and 100 smart projects will bring in billions of dollars in investment. North America is predicted to grow fastest in the global Tungsten Carbide market during the projected timeframe. Numerous research organizations and agricultural firms are raising demand for the global Tungsten Carbide market. Furthermore, the rising trend of precision farming or agriculture increases the demand for Tungsten Carbide technology.

Safe chip removal during the milling process was another focus during tool development as a basic requirement for good surfaces. The structural dimensions and neck transition geometries of the new milling cutters have therefore been optimised for use in deep and narrow contours. All micro milling cutters in the new range also consist of revolver blanks with GühroJet periphery cooling. With this innovative technology for internal cooling, chips are removed directly and safely from the machining zone by air, minimum quantity lubrication (MQL) or cooling lubricant.

The cemented carbide segment is anticipated to dominate the global tungsten carbide market during the projected timeframe. Based on the application, the global tungsten carbide market is divided into cemented carbide, coatings, alloys, and others. Among these, the cemented carbide segment is anticipated to dominate the global tungsten carbide market during the projected timeframe. It is utilized in the mining and construction industries for chipless shaping, timber machining, composite substances, metal cutting, plastics, soft ceramics, wear parts, structural parts, and military equipment.

The report offers the appropriate analysis of the key organizations/companies involved within the global market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market. Major vendors in the Global Tungsten Carbide Market are A.L.M.T. Corp., Allegheny Technologies Incorporated, Almonty Industries Inc., Betek GmbH & Co. KG, Buffalo Tungsten Inc., China Minmetals Non-Ferrous Metals Co., Ltd., China Molybdenum Co., Ltd., Chongyi Zhangyuan Tungsten Co., Ltd, Guangdong XiangLu Tungsten Co. Ltd., H.C. Starck GmbH, International Metalworking Companies, Jiangxi Tungsten Holding Group Co., Ltd., Kennametal, Inc., Nippon Tungsten Co., Ltd, and other key vendors.

Mould making plays a key role in many industries and mould makers place high demands on cutting tools – after all, they are a key component in ensuring product quality. This is why Gühring has presented a new milling cutter range for high-precision finishing requirements. The combination of new geometry, adapted coating system and ultra-hard substrate makes the high-precision milling cutters so successful when used in hardened tool steel.

The precision blanks also have optimised shaft tolerances in the h5 range and are μ-precise in diameter, concentricity and roundness. The radius tolerances are even in the range of +- 5 μm. The coating system has also been specially adapted for mould making: A Perrox coating produced using the HiPiMS process makes the tool surfaces extremely smooth and therefore very resistant to wear. Thanks to this combination of carbide, coating and geometry, the new high-precision milling cutters promise a significant increase in performance – both in soft and harder materials up to 65 HRC and even in high-alloyed or powder metallurgically manufactured tool steels.

Harder substrate, extremely smooth layer Because tool and mould making involves machining high-strength and hardened steels, Gühring has adapted its carbide substrate to these materials with the new high-precision milling cutters: The cutting material is now around 200 HV harder and finer-grained. This ultra-hard solid carbide substrate guarantees very good edge stability and thus process-reliable service life in hard machining.

Maximum angular and fit accuracy Whether plastic, metal, glass or chocolate, moulding is what turns raw materials into products. Because these moulds produce the surfaces of the finished components, maximum precision is required here: Only a perfectly manufactured mould can produce a final product with tolerances and surfaces that meet the required quality without reworking. For perfect part quality, mould makers rely on tools that guarantee process reliability, precision and repeatability. The Swabian tool manufacturer Gühring meets precisely these requirements with a new range of high-precision milling cutters.

The new μ-precise micro milling cutter “MikroMill µ55 U” meets high demands in the micro range: Very high-quality surfaces can be achieved with the tightest tolerances and precise concentricity. An FEM-optimised radius angle transition also ensures maximum radial rigidity and low displacement during micro-milling. The innovative GühroJet internal cooling increases the service life of the tool and ensures process reliability.

The solid, light gray, metal-like inorganic chemical compound known as tungsten carbide (WC) is created when tungsten and carbon black are melted in the presence of hydrogen. It is possible to press and shape it into several shapes during the sintering process. A wide range of products, including abrasives, armor-piercing shells, tools for cutting, jewelry, alloys, coatings, and mill goods, utilize tungsten carbide. It is a durable substance that is stronger, less electrically conductive, has a higher melting and boiling point, is harder, and resists heat, rusting, scratches, and scratches. As a result, tungsten carbide is used extensively in the automotive, electronics, sports, mining and construction, aerospace, and defense industries. Additionally, due to its exceptional hardness, strength, and resistance to wear, tungsten carbide powder is a preferred material for industrial use. The growth of the automotive, aerospace, oil & gas, mining, and construction industries is the primary driver of the requirement for tungsten carbide powder, which is utilized in tools, cutting inserts, wear parts, and other components. As a result, the market is developing as a result of the increasing use of tungsten carbide powder in various industrial sectors. In the mining and construction sectors, tungsten carbide powder is frequently used for wear-resistant parts, mining equipment, and drilling tools.

Asia Pacific is expected to hold the largest share of the global tungsten carbide market over the forecast period

18581906093

18581906093