Inserts and holders enable all-directional and high-feed turning - cnc all insert

In this interview, AZoM talks to Philippe Wilson about benchtop NMR and its role in different fields, focusing on its main use in biofluid analysis.

The undoped CVD diamond films have a nine-layer architecture with two different morphologies viz. nanocrystalline diamond (NCD) and sub-microcrystalline diamond (SMCD). The increase in grain size increase the density of grain boundaries of the coating, which improves the cutting performance.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

While we only use edited and approved content for Azthena answers, it may on occasions provide incorrect responses. Please confirm any data provided with the related suppliers or authors. We do not provide medical advice, if you search for medical information you must always consult a medical professional before acting on any information provided.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Hanita is a solid end milling brand devoted to delivering high-performance tools for the most demanding operations and applications in the aerospace, energy and general engineering industries.

Key characteristics of VariMill Xtreme are its versatility whereby it is capable of machining a broad range of materials (steel, stainless steel, cast iron, super alloys), provides high-performance and tool life in a variety of operations including ramping, slotting, plunging, drilling, helical interpolation, dynamic milling, is productive with improved chip evacuation and increased edge/corner strength to reduce any risk of breakage while pushing the cutting parameters to the limit and exceeds expectations in aggressive cutting parameters.

The coating of the tool is a Victory WS15PE grade and custom solutions are available. Regrinding is offered through the existing global centres.

This corresponds to a resistivity of approx. 900 W.cm. The response time of the diamond thermistor closely matches the response time of the thermographic camera with an average delay of ~1 s. The BDD thermistor shows an average voltage variation of 16.5 mV in the photodiode, due to the difference between the highest temperature at inflection positions of the cutting tool and the lowest temperature at the mid path.

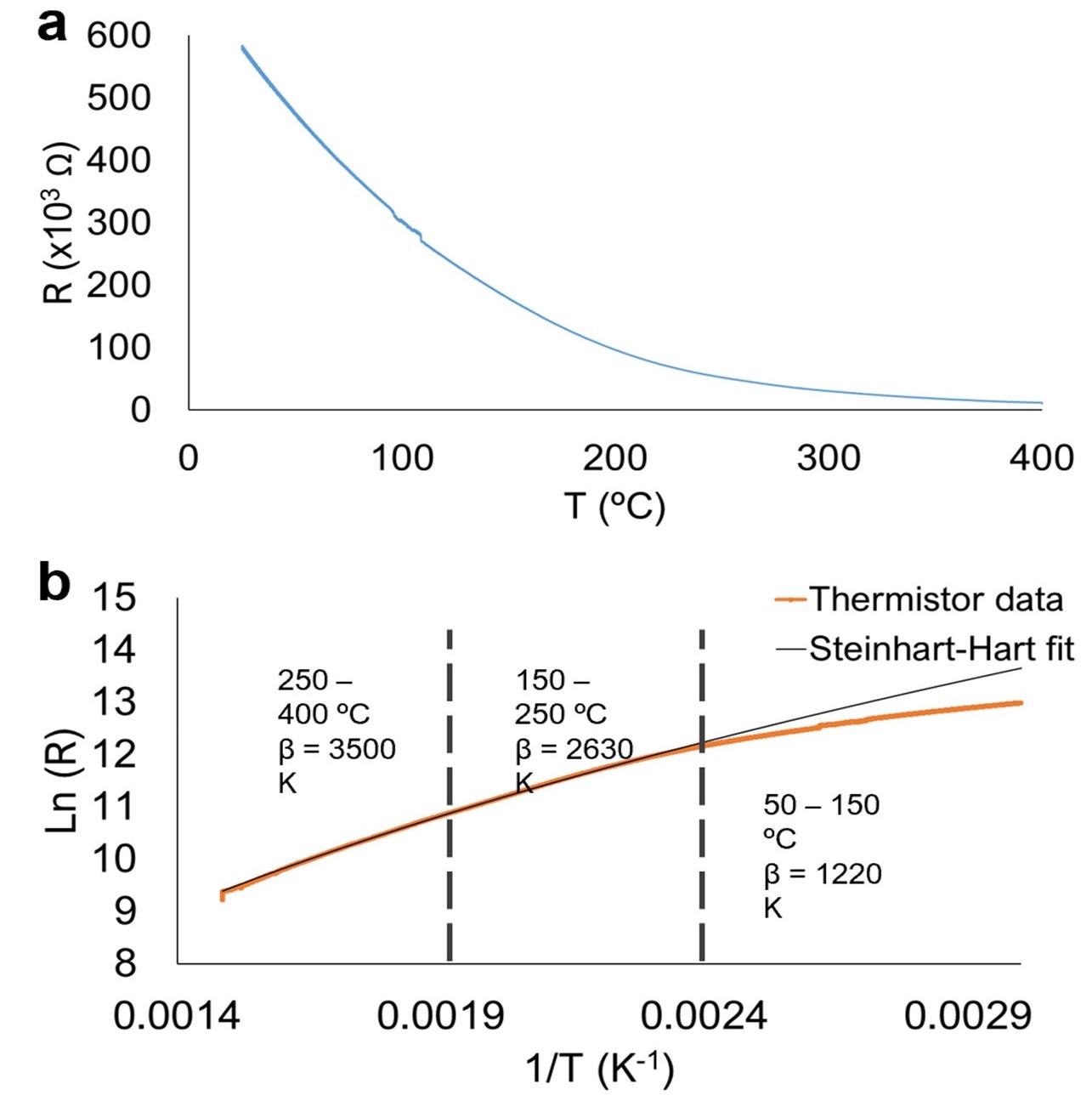

Resistance variation of the diamond NTC thermistor in the range 25–400 °C. (a) Measured curve. (b) Linear regression and fitting according to the “beta” and Steinhart-Hart models. Image Credit: Pratas, S et al., Materials

Researchers from Portugal recently developed an effective thermistor-type temperature monitoring method for boron-doped diamond-coated carbide cutting tools. It overcomes the limitations of the traditional temperature measurement approach with thin-film thermocouples and infrared thermography in certain cutting scenarios. This study is available in the journal Materials.

Target markets include the aerospace and energy industries as well as a host of general engineering industries.

Subsequently, a thermistor is fabricated by the deposition of a BBD film on top of a silicon nitride (Si3N4) insulating substrate. Here, argon is used as the carrier gas for boron dopant in HFCVD. The carrier gas is bubbled through a B2O3/ethanol solution and deposits on the Si3N4 substrate.

These chemically treated specimens are coated with diamond powder to form multilayer diamond films in a hot filament-assisted CVD (HFCVD) reactor. The films are composed of nanocrystalline diamond (NCD) and sub-microcrystalline diamond (SMCD).

Then, tungsten oxide (WO2) is vaporized from the tungsten hot filaments at 1800 ℃ followed by the reduction of WO2 in presence of hydrogen and methane to form ohmic tungsten carbide WC contacts.

In situ temperature-monitoring methods such as infrared (IR) thermography and thermocouples provide good approximations of the metal surface temperature, but there are certain limitations for both.

Prakash Rout, Bismay. 2021. Boron-Doped Diamond Thermistor for Thermal Sensing of Diamond Coated Cutting Tools. AZoM, viewed 22 September 2024, https://www.azom.com/news.aspx?newsID=57557.

“VariMill Xtreme will dominate the shop floor through productive output due to its versatile offering and ability to machine a broad range of materials in aggressive machining conditions” said a company spokesperson.

Hence, an accurate measurement can only be attained if the emissivity of the work object is well known throughout each specific range of varying machining conditions. Thermocouples suffer from the physical accommodation of wiring in tools and also provide inaccurate temperature readings since the hot junction of the thermocouple cannot be positioned directly at the machining interface, where maximum heat is generated.

Pratas, S., Silva, E.L., Neto, M., Fernandes, C., Fernandes, A., Figueiredo, D., Silva, R., Boron Doped Diamond for Real-Time Wireless Cutting Temperature Monitoring of Diamond Coated Carbide Tools. Materials, 2021, 14, 7334. https://www.mdpi.com/1996-1944/14/23/7334

Bismay is a technical writer based in Bhubaneshwar, India. His academic background is in Engineering and he has extensive experience in content writing, journal reviewing, mechanical designing. Bismay holds a Masters in Materials Engineering and BE in Mechanical Engineering and is passionate about science & technology and engineering. Outside of work, he enjoys online gaming and cooking.

Measure material stiffness and resiliency with precision up to 10,000 units with Taber's Stiffness Tester. Learn more here.

In this study, a BBD-based thermistor is fabricated by HFCVD to monitor the temperature variation during the milling of an Inconel workpiece using a DCC cutting tool. The linear regression of the characteristic resistance-temperature dependence of the BDD thermistor indicated higher temperature sensitivity in the temperature range of 250 to 400 ℃.

After the iconic VariMill I design, Widia Hanita are pleased to present the recently released VariMill Xtreme, the next generation of versatile high-performance end mills.

Experimental setup for Hot Filament Chemical Vapor Deposition of (a) undoped diamond on carbide end mills and (b) boron-doped diamond on a silicon nitride substrate for thermistor fabrication. Image Credit: Pratas, S et al., Materials

Prakash Rout, Bismay. "Boron-Doped Diamond Thermistor for Thermal Sensing of Diamond Coated Cutting Tools". AZoM. 22 September 2024. .

Prakash Rout, Bismay. "Boron-Doped Diamond Thermistor for Thermal Sensing of Diamond Coated Cutting Tools". AZoM. https://www.azom.com/news.aspx?newsID=57557. (accessed September 22, 2024).

For more information contact Widatech on TEL: +27 11 450 2108, email: info@widatech.co.za or visit www.widatech.co.za

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

The product offering of the 4-flute solid carbide end mill is it is available in metric (57 sku) and inch (57 sku) standard diameters, straight and Weldon shanks and square-end, sharp edges, chamfers and corner radii designs are available.

To launch VariMill Xtreme Widia Hanita will hold a webinar – Discover WIDIA Hanita VariMill Xtreme – on 21 January 2021 (2PM CET). To register for this webinar visit https://attendee.gotowebinar.com/register/8464220142692582672

Your questions, but not your email details will be shared with OpenAI and retained for 30 days in accordance with their privacy principles.

In this interview, Prolific North's Managing Director Alexandra Balazs discusses the launch of the inaugural STEM Marketing Awards, sharing insights into why they’re crucial for the sector and how they aim to shape the future of STEM marketing.

When the temperature increases the electrical resistance of the BDD thermistor decreases. BBD also exhibits high chemical inertness, thermal conductivity, and mechanical robustness for applications under harsh working conditions.

Discover the PinAAcle 900 spectrometer series that provides cutting-edge precision for atomic absorption.

In the metal and alloy machining industry, productivity is directly dependent upon process parameters such as cutting speed and feed rate. Hence, an increase in productivity can be achieved by optimization of the cutting cycle, increasing tool lifetime, and minimization of downtime. Two major factors, cutting force and cutting temperature, affect tool life. Thus, effective monitoring of cutting temperature can improve machining productivity.

Heat generates at three primary zones during machining viz. the primary shear-zone (the plastic deformation at the interface of the machining tool and the workpiece), the secondary shear-zone (the friction at the interface of the tool and moving chips), and the tertiary deformation zone (the friction between flank face and the machined surface).

Temperature measurement recorded by the thermographic camera shows the occurrence of lower temperature at the tool tip when approximately at the middle of the cutting path and higher temperature at inflection positions. This curve was used for calibration of the diamond-based thermistor, for which the resistance variation induced a 0.84 mV/°C variation at the photodiode. Image Credit: Pratas, S et al., Materials

Prakash Rout, Bismay. (2021, December 03). Boron-Doped Diamond Thermistor for Thermal Sensing of Diamond Coated Cutting Tools. AZoM. Retrieved on September 22, 2024 from https://www.azom.com/news.aspx?newsID=57557.

Study: Boron Doped Diamond for Real-Time Wireless Cutting Temperature Monitoring of Diamond Coated Carbide Tools. Image Credit: GRADIENT BACKGROUND/Shutterstock.com

The prepared BDD thermistor demonstrates higher sensitivity in the higher temperature range. This behavior is attributed to a hopping conduction mechanism at low temperatures, which is due to the low doping level of the diamond film (~600 kW at 25 ℃).

In this study, first, a diamond-coated carbide tool (DCC) is fabricated by depositing undoped diamonds on the tungsten carbide tool. The 7 wt.% cobalt cemented tungsten carbide (WC) grains are attacked with Murakami reagent for surface roughening followed by immersion in H2SO4 and H2O2 solution for cobalt etching.

Key features of the VariMill Xtreme are a twisted end face, an asymmetrical divided flute and variable helix angle and a parabolic core.

Engineered to excel in a variety of aggressive machining conditions the product design uses key features of the already successful VariMill I but enhances chip evacuation and corner stability to exceed performance expectations on a wide range of materials.

Moreover, the BBD thermistor exhibits a faster response and minor average variation of 0.84 mV/ ℃ than its counterpart IR thermography. To conclude, BBD thermistor is an effective, fast responsive, real-time, and in situ temperature monitoring solution for the heavy machining industry.

Kai Düffels from Microtrac discusses the CAMSIZER 1, a particle size analyzer designed for simplicity. Read the interview here.

Thermistors are temperature sensors calibrated by the dependency of resistance on temperature variation. Boron doped diamond (BDD) films developed by chemical vapor deposition (CVD) exhibit excellent temperature sensitivity.

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

Temperature monitoring with thermographic cameras is very sensitive to the emissivity of work material, which depends on factors like surface roughness, measurement angle, and the temperature of the surface being measured.

18581906093

18581906093