[Solved] Reaming is a process used for - reaming operation

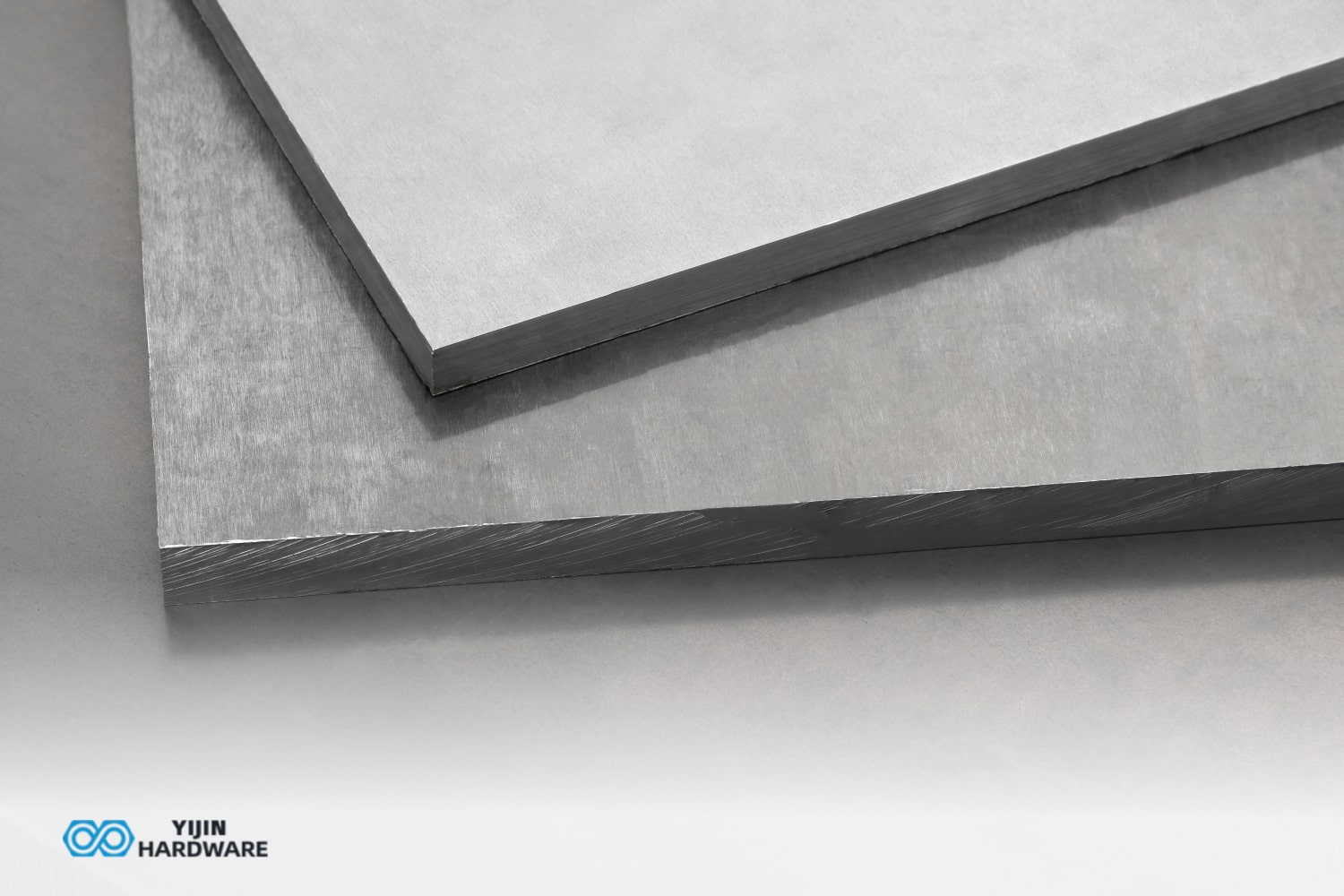

Aluminum is a versatile material that can be cut and shaped easily, but you should pay attention to it. To achieve the outcomes you desire, you will need to know the best ways to deal with them.

But the primary factor to high performance when machining aluminum is the right flute count and helix angle for your job.

Milling aluminum is a challenging process because Aluminum is a sticky material that can easily melt and fuse to the tool.

Depth of cutformula for milling

Additionally, Aluminum is a difficult material to mill due to the amount of friction and heat generated during the process.

Aluminum is a metal that has several properties that make it ideal for milling. For one, Aluminum material is soft and malleable, which means it can be easily shaped in a machine.

Different operations and rigidity can also affect the choice of tool. 2 flutes are the best choice for Aluminum because of the big chip it leaves behind.

Combined with the right chip breaker tooling, it can help create an efficient and effective process for machining aluminum parts.

The optimum helix angle for a given application depends on several factors, including the material being cut and the desired finish.

Depth of cutCalculator

6061 aluminum is one of the most flexible and widely used aluminum alloys, known for its fantastic mechanical properties and corrosion resistance. Among the different

To stay ahead of the competition and make your shop run more smoothly, you must ensure that your tool crib, machine setups, and toolpaths are all optimized for Aluminum.

Cast Aluminum, on the other hand, is more flexible but less strong. In the end, the aluminum type you use will rely on what your project needs.

Aluminum is lightweight, strong, and corrosion-resistant. These properties make Aluminum an excellent choice for various applications, including automobile parts to aircraft construction.

Depth of cutformula for turning

For cast aluminum alloys like 308, 356, and 380, the surface footage should be between 500 and 1000 SFM. The RPMs should also change based on the diameter of the cutter, using the formula (3.82 x SFM) / Diameter.

However, a higher helix angle (45°) is often used for finishing operations. This provides more aggressive cutting action and helps to reduce harmonics and chatter.

Depth of cutin drilling

It is a roughing technique that uses both a high ADOC and low RDOC (a high Axial Depth of Cut and Radial Depth of Cut) to take full advantage of the tool’s cutting edge.

When machining aluminum, setting the right parameters to get the most out of your work is important. Some broad guidelines should be observed, although the parameters for each job also depend on many other factors.

Aluminum is used for a variety of applications, such as in aircraft components, automotive parts, and packaging. Pure aluminum is a chemical element with the

Anodized aluminum is aluminum that has gone through an anodizing process, resulting in a strong, corrosion-resistant, and visually appealing surface. This process improves the natural

Many CAM programs now offer HEM toolpaths, though any machine can technically perform HEM if the CNC controller features a fast processor.

In milling, the depth of cut is two-dimensional. The Axial depth of cut (AP or ADOC), is the length that the tool engages a workpiece in its axis direction as it moves perpendicular to it. Other terms that have the same meaning are Stepdown and Cut Depth.

Use high-speed steel or carbide tools: these materials are able to withstand the extremely high temperatures that are produced during aluminum machining.

Depth of cutformula

Regarding tooling, there are a few different coating options available. One of the most chosen options is ZrN, a gold-colored coating.

With their perfect balance and high-speed capabilities, these tools can help you get the most out of your machining center.

Aluminum is available in two major types: cast and wrought. Wrought Aluminum is stronger and can handle heat better than cast Aluminum, but it is also more expensive.

Most of the time, 2-flute or 3-flute standard tools are enough to machine aluminum. But for some application domains and machine arrangements, there are a few more tooling choices to consider if you want to get even better results.

Depth of cut definitionlathe

When machining aluminum, chip evacuation is essential to keep in mind. Two- and three-flute end mills can do a good job removing chips, but using a 3-flute chip breaker tool can produce even better results.

Best CNC Machined Parts Manufacturer and Factory in China.Offer Fast and Cost-Effective One-Stop CNC Machining Services.Free Machined Parts Design to Your Projects with Fast Turnaround Times.

These are designed to improve performance in machining centers that are already well-balanced and can run at high RPMs and feed rates.

Cutting speeddefinition

Please attach your 2D CAD drawings and 3D CAD models in any format including STEP, IGES, DWG, PDF, STL, etc. If you have multiple files, compress them into a ZIP or RAR. Alternatively, send your RFQ by email to info@yijinsolution.com.

Another important tool for machining aluminum is High-Efficiency Milling. This technique uses specialized toolpaths to increase material removal rates while reducing wear on the cutting tools.

With over 10 years of experience in precision manufacturing, we specialize in on-demand machining solutions and customized parts. Contact us for a quote on your current or future projects!

Depth of cut definitionlathe machine

Higher helix angles (40° or above) are typically best for this material, as they provide better chip clearance and help to prevent premature tool wear.

High-balance end mills can help improve productivity in any machining center, but they are especially well suited for aluminum machining.

An instrument’s helix angle is defined as the degree to which the tool’s longitudinal axis deviates from a straight line perpendicular to the cutting edge.

There are many other factors to consider when setting parameters for aluminum machining jobs, but following these general guidelines is a good place to start.

The coolant-through 3-flute tools reduce heat, improve chip removal, and increase material removal rates. Like the chip breakers, these tools are also a great option for high efficiency.

For conventional roughing and slotting, a 35 or 40-degree helix angle is typically recommended. These angles provide a good balance between cutting speed and chip clearance.

This allows for greater efficiency, extended tool life, and better performance overall, especially when machining aluminum.

The debate over whether to use a 2-flute or 3-flute end mill for Aluminum has raged on for years. Both have pros and cons, but it comes down to personal preference.

The aluminum chips produced by the milling process can also be very dangerous if they are inhaled, so worker safety is a major concern.

Another option is TiB2, a less well-known but highly effective coating. Both of these coatings help to improve the lifespan of the tooling and increase its efficiency.

18581906093

18581906093