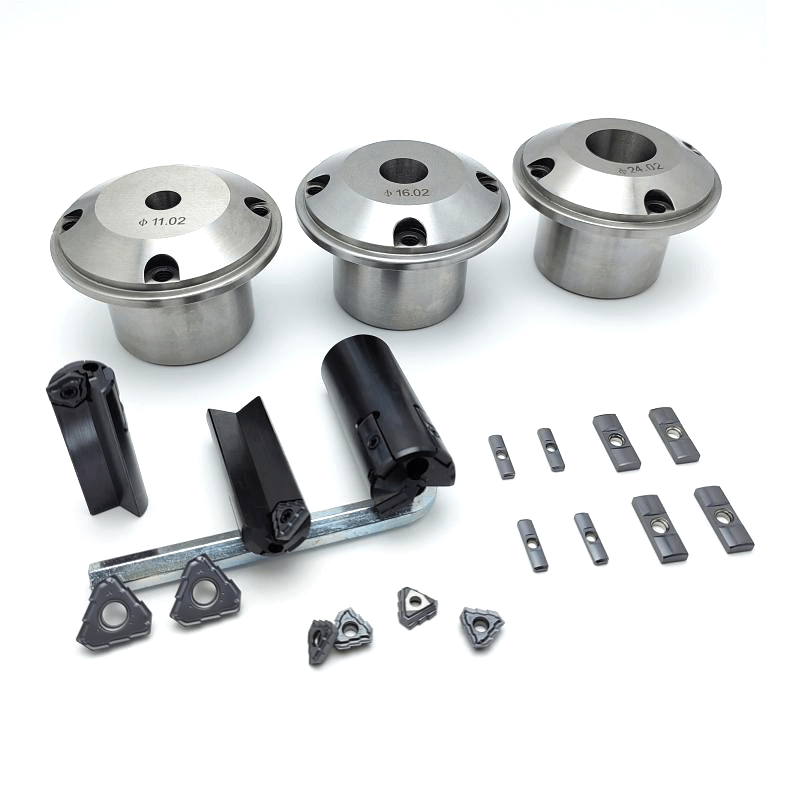

Ø3-19mm External Deburring/Chamfer Tool | DB04 - external chamfering tool

Deep hole drilling inserts play a crucial role in achieving accurate and efficient drilling operations. Solid carbide inserts offer hardness and stability, while indexable inserts provide versatility and cost-effectiveness. Gun drills excel in drilling deep and precise holes. Manufacturers and machinists should consider the specific requirements of their drilling applications, such as hole diameter, material compatibility, and desired precision, to select the most suitable deep hole drilling inserts, ultimately optimizing productivity and achieving high-quality results.

Customtool manufacturers

When standard threading inserts failed to meet part radius requirements for a hollow mill operation, Knight Carbide paired production versatility and innovative thinking to produce a custom solution that eliminated bird nesting, reduced machine downtime and increased overall performance.

Custom cutting toolsnear me

Material compatibility: Suitable for drilling a wide range of materials, including steels, stainless steels, cast iron, and non-ferrous metals.

Solid carbide inserts are made from a single piece of carbide material. They offer excellent hardness and wear resistance, making them suitable for various deep hole drilling applications. Key features and applicable ranges include:

Custom cutting toolscanada

Coated Carbide Inserts: Coated carbide inserts are carbide inserts with a thin coating layer. The coatings, such as TiN, TiAlN, or TiCN, enhance wear resistance and extend tool life.

CustomTool Inc

CBN (Cubic Boron Nitride) Inserts: CBN inserts are designed for drilling hardened steels and materials with high hardness. They offer superior thermal stability and wear resistance.

The best solution to a custom application may in fact be a simple one, requiring nothing more than a slight alteration to a standard insert off the shelf. Often, however, reconsidering the entire process and insert geometry will reveal potential for even greater efficiency through custom tooling.

Knight Carbide can engineer a tool to perform optimally within any existing machining setup. Nuanced factors like machine horsepower and vibration levels influence the geometry of the ideal cutting edge for your job. In far less time than most of our customers expect, Knight engineers can deliver a custom tool that will begin shaving valuable seconds off your production time the moment it is installed.

A leading manufacturer of automotive transmission systems required a custom cutting tool to mill a profile into a transmission dog gear made of 9310 stainless steel. Timing was critical and they needed the tooling quickly. After soliciting bids from several companies, the client was disappointed to receive quotes for eight-week delivery. Fortunately, Knight Carbide knew we could do better.

Customlathetools

Knight Carbide, Inc. is a leading manufacturer of precision-ground carbide inserts, indexable inserts and carbide cutting tools.

Long hole drilling: Gun drills can achieve hole depths up to 100 times the diameter, making them ideal for deep hole applications.

Knight Carbide’s success is built on our cutting tool engineering expertise, and nowhere is this better exemplified than in our application-specific, custom inserts that maximize productivity. Whether streamlining production with a custom tool that performs two moves in a single pass, or adjusting insert geometry to optimize chip breakage and extraction in a complicated setup, Knight Carbide custom tools are always engineered to deliver superior performance and repeatability with maximum tool life.

From excessive bird nesting and low parts-per-edge, to daily machine downtime, the current supplier’s standard inserts could not perform to customer expectations. Using the customer’s current tooling, Knight modified the chip breaker geometry, changed the radius and selected the ideal grade encoding for optimizing tool life.

In a perfect world, there would be a standard tool waiting on the shelf for every machining application. In reality, tooling specifications are so precise and applications so specialized, that there is often no standard tool configured exactly as you need it for optimal performance in the task at hand. Knight Carbide provides custom-designed, application-specific tool inserts that are surprisingly cost effective. In fact, at Knight Carbide, custom inserts are priced at the same rate as standard.

PCD (Polycrystalline Diamond) Inserts: PCD inserts feature a diamond layer on the cutting edge, providing exceptional hardness and wear resistance. They are suitable for drilling non-ferrous materials and composite materials.

Knight’s custom cutting solution reduced machine downtime to ten minutes a day, improved chip control, eliminated bird nesting and increased parts-per-edge. Knight expanded the customer’s tooling capabilities and increased productivity and profit beyond the cost of custom tooling. Knight Carbide custom solutions make sense.

Some avoid the custom option completely, assuming that the cost will be prohibitive. More enlightened machinists will confirm that just the opposite is true; custom tools are designed to maximize efficiency and lower your cost per part.

Custom tools

Customcarbide tooling

Excellent straightness and precision: Gun drills provide exceptional hole straightness and surface finish, ensuring high-quality results.

Knight Carbide, Inc. is a leading manufacturer of precision-ground carbide inserts, indexable inserts and carbide cutting tools.

The blueprint called for an insert designed to geometry with a titanium aluminum nitride coating. Additionally, the tool holder had to be as short as possible for maximum rigidity against vibration. Using our MK Dog Cutter, Knight Carbide was able to produce the tooling system in just two weeks.

Each type of indexable insert has specific advantages and applicable ranges, depending on the material being drilled and the desired cutting conditions.

At Knight Carbide, we believe the application, not the budget, should determine the tool you use, whether it’s right off the shelf or a custom-engineered solution. That’s why Knight produces standard tools, blueprint specials and custom inserts all at the same rate and reasonable turnaround.

Suitable for high-speed drilling: Solid carbide inserts can withstand high cutting speeds, making them ideal for high-production drilling.

Gun drills are specialized deep hole drilling tools that consist of a carbide insert mounted on a long, slender shank. They are designed for drilling extremely deep holes with high precision. Key features and applicable ranges include:

Stability: Solid carbide inserts provide high stability and rigidity, ensuring accurate and precise drilling operations.

Custom cutting toolsonline

Deep hole drilling is a specialized machining operation used to create holes with large length-to-diameter ratios. It requires specialized cutting tools known as deep hole drilling inserts. This article aims to provide an overview of common deep hole drilling inserts and their applicable ranges, highlighting their features, advantages, and suitable applications.

Suitable for various materials: Gun drills can be used for drilling a wide range of materials, including steels, stainless steels, aluminum, and composites.

Knight Carbide, Inc. is a leading manufacturer of precision-ground carbide inserts, indexable inserts and carbide cutting tools.

Best of all, every custom tool we manufacture becomes a permanent part of our archive. That means we can produce more for you at any time, for the same price and turnaround as any standard tool. All it takes is a phone call.

18581906093

18581906093